Installation structure for assembly type adjustable partition

An installation structure and adjustable technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of slow progress, high installation cost, inconvenient maintenance, etc., and achieve the effects of convenient disassembly and assembly, low installation cost, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

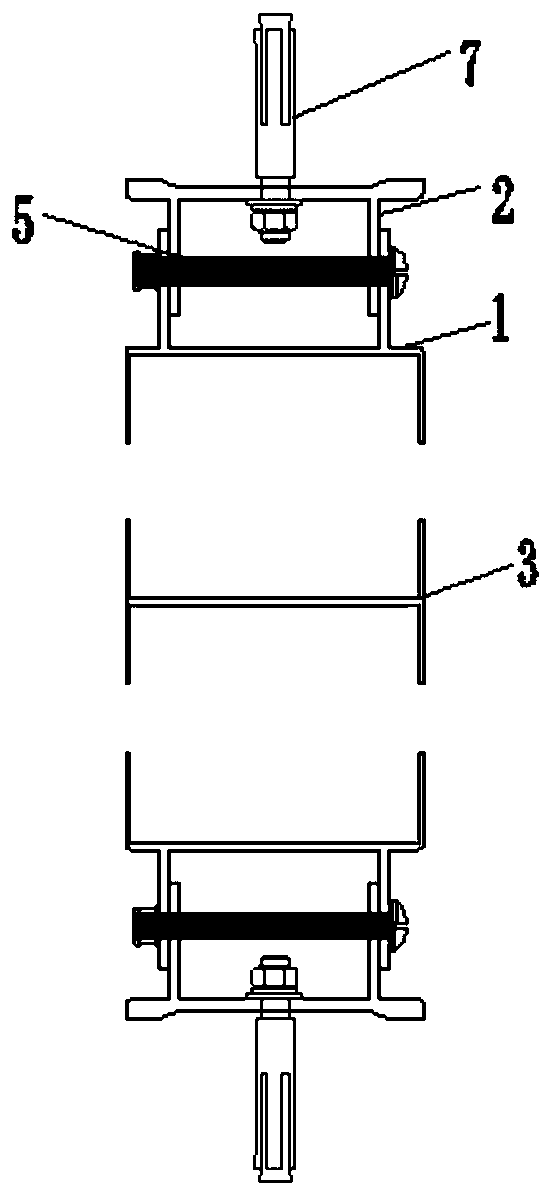

[0037] see Figure 1-2 , Figure 9 , the figure shows a prefabricated adjustable partition wall installation structure provided by Embodiment 1 of the present invention, including: an adjustment base, which is symmetrically arranged on the top of the wall and the ground, and the adjustment base includes a base 1 and its corresponding Connected abutment 2, wherein one abutment 2 is fixedly connected to the top of the wall, and the other abutment 2 is fixedly connected to the ground, and the two bases 1 are arranged up and down opposite to each other; the middle keel 3 is located in the middle of the two adjustment bases and is fixed on the On the side wall; the partition wall assembly, which includes a partition wall frame 41 and a plurality of decorative panels 42 arranged in the partition wall frame 41, and an installation groove 43 is arranged between adjacent two decorative panels 42, and the installation groove 43 and the middle keel 3-phase clamping connection; the inner...

Embodiment 2

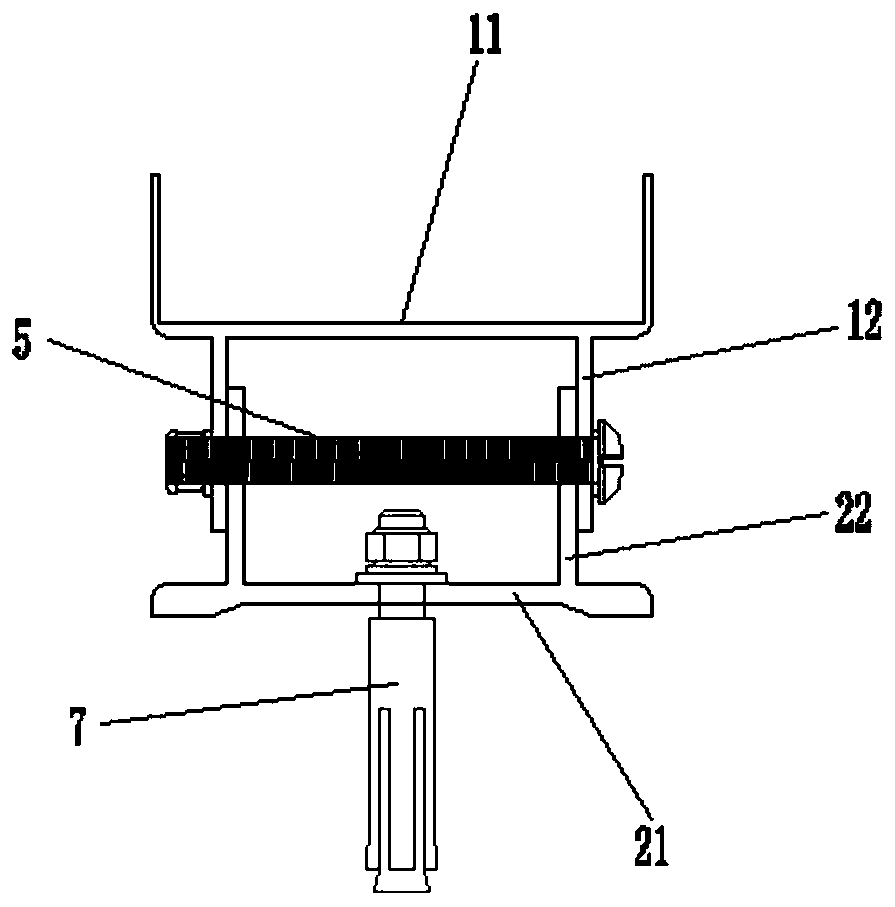

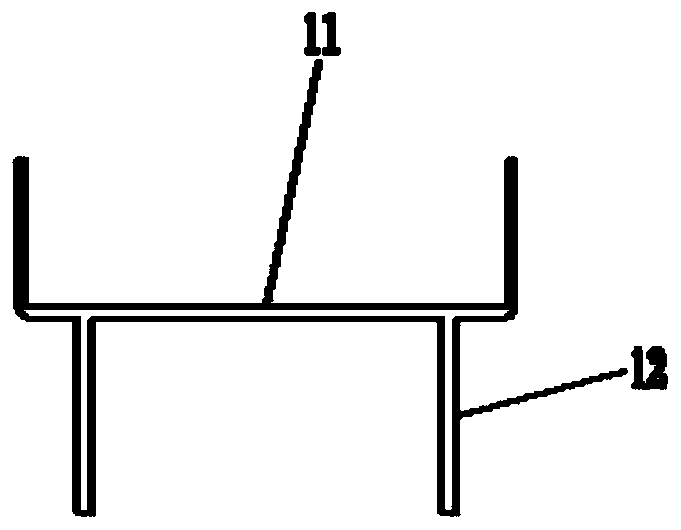

[0046] see Figure 2-4 , Figure 6-7 , the figure shows the installation structure of a prefabricated adjustable partition wall provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The seat 1 includes a carrier frame 11 and a connecting plate 12 arranged at the bottom of the carrier frame 11, and the abutment 2 includes a bottom plate 21 and a side plate 22 arranged on the bottom plate 21; the connecting plate 12 and the side plate 22 are arranged in pairs, and the side plate 22 Located on the inner side of the connecting plate 12. Through the setting of the above structure, the base 1 and the base platform 2 are connected through the connection plate 12 and the side plate 22, and the connection effect is good.

Embodiment 3

[0048] see Figure 1 to Figure 2, the figure shows the installation structure of a prefabricated adjustable partition wall provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Adjust The base also includes a connecting piece 5, the connecting piece 5 passes through the connecting plate 12 and the side plate 22 in turn, and connects the connecting plate 12 and the side plate 22 fixedly; the adjusting base also includes a fixing piece 7 for connecting the abutment 2; wherein , the connecting piece 5 is a long bolt, and the fixing piece 7 is an expansion screw. Through the setting of the above structure, the connecting part 5 further improves the connection effect between the base 1 and the abutment 2, and at the same time, the fixing part 7 ensures the connection strength between the abutment 2 and the top of the wall and the ground respectively, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com