Automatic-speed-changing textile fabric ironing device

A textile cloth and ironing device technology, applied in the textile field, can solve the problems of low ironing efficiency, textile cloth scalding, insufficient ironing, etc., to avoid incomplete ironing, strong penetration, and prevent scalding damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

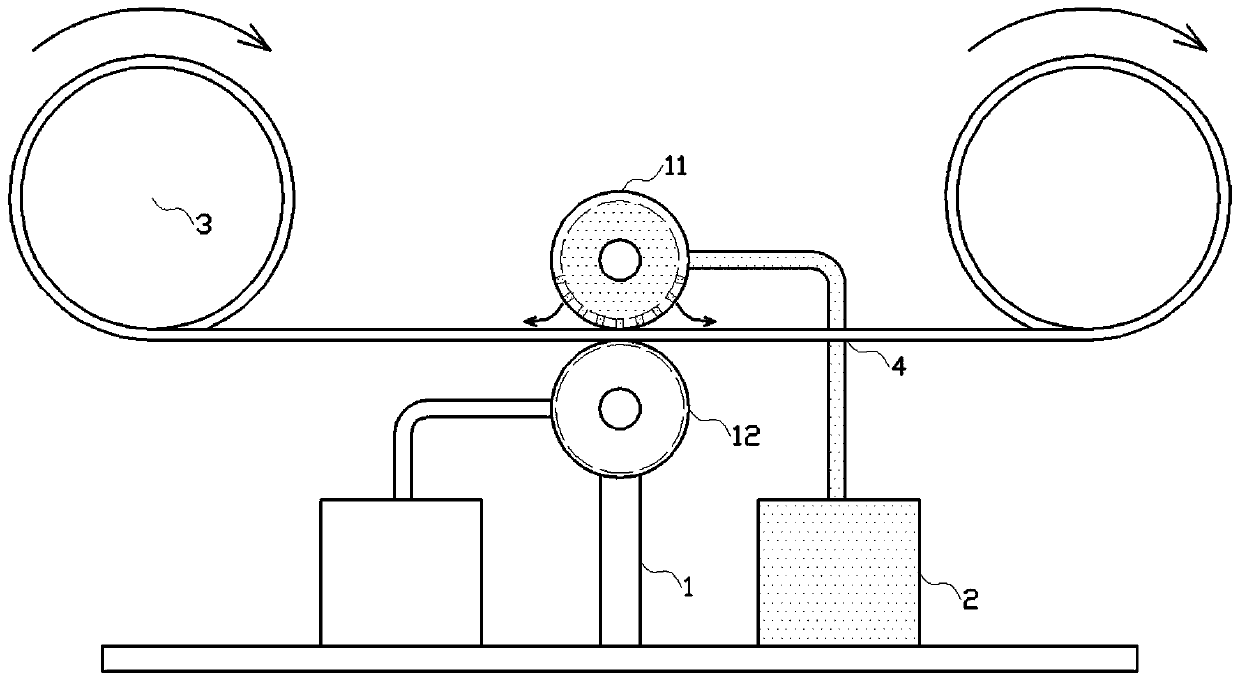

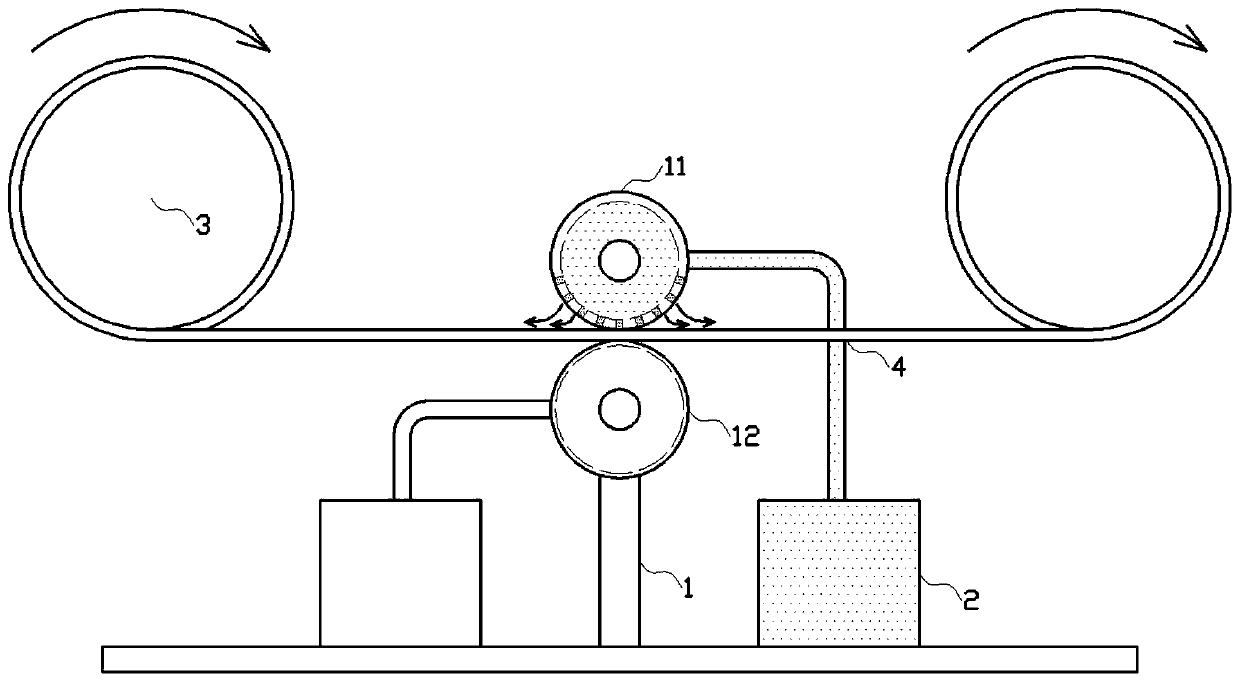

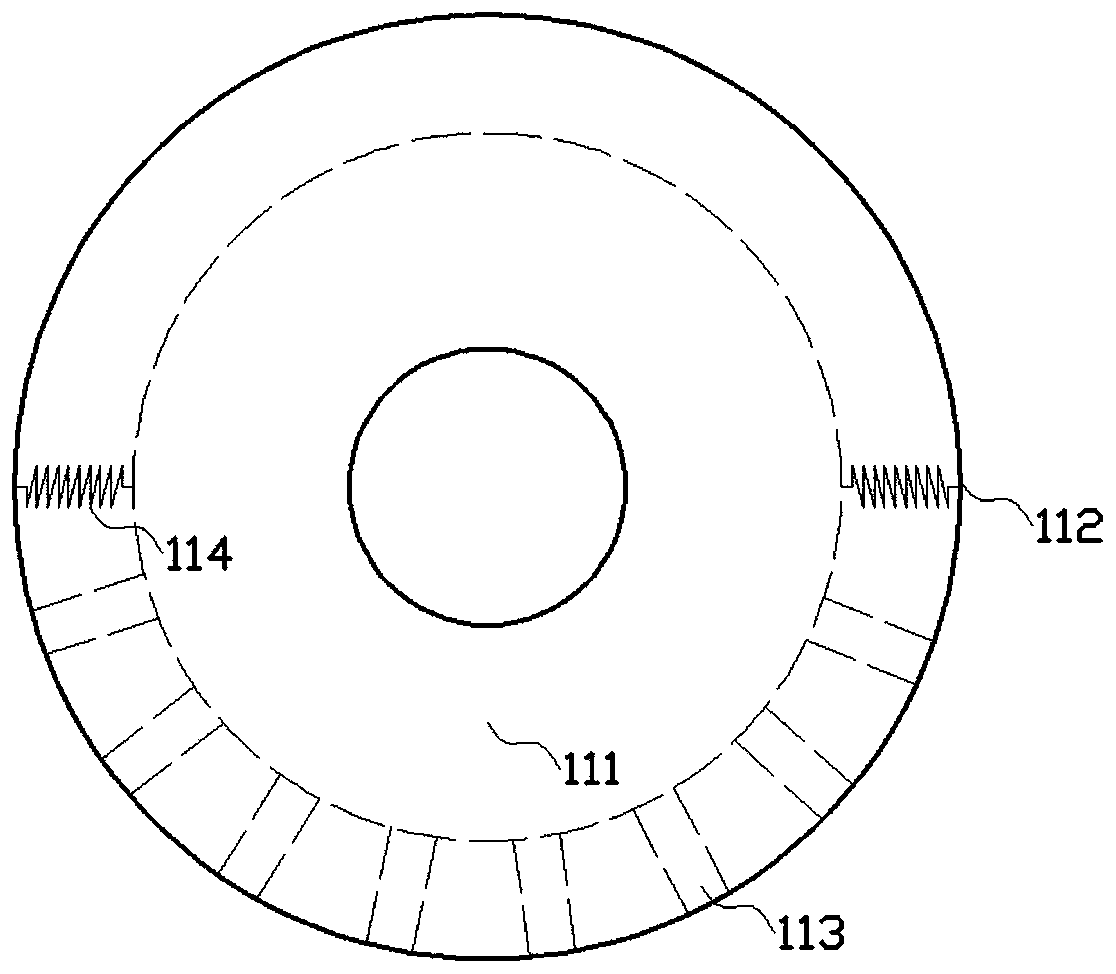

[0013] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the automatic variable speed textile cloth ironing device is a kind of uniform rolling of the cloth through the roller, and at the same time, the surface of the cloth is subjected to high temperature humidification treatment, so that the cloth can be uniformly ironed; in addition, according to A device that automatically adjusts the amount of steam when ironing textile fabrics of different thicknesses, thereby effectively improving the ironing efficiency of the fabrics. It includes an ironing module 1, a steam module 2 and a conveying module 3; the ironing module 1 includes a pressing roller 11 And the top roller 12, the pressure roller 11 includes an outer roller 112 and an inner roller 111; the lower end of the outer ring surface of the outer roller 112 is provided with a steam hole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com