Fitting assembly

A technology of accessories and components, applied in the direction of building fastening devices, buildings, building structures, etc., can solve problems such as high cost and complex structure, and achieve the effect of simplifying the length adjustment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

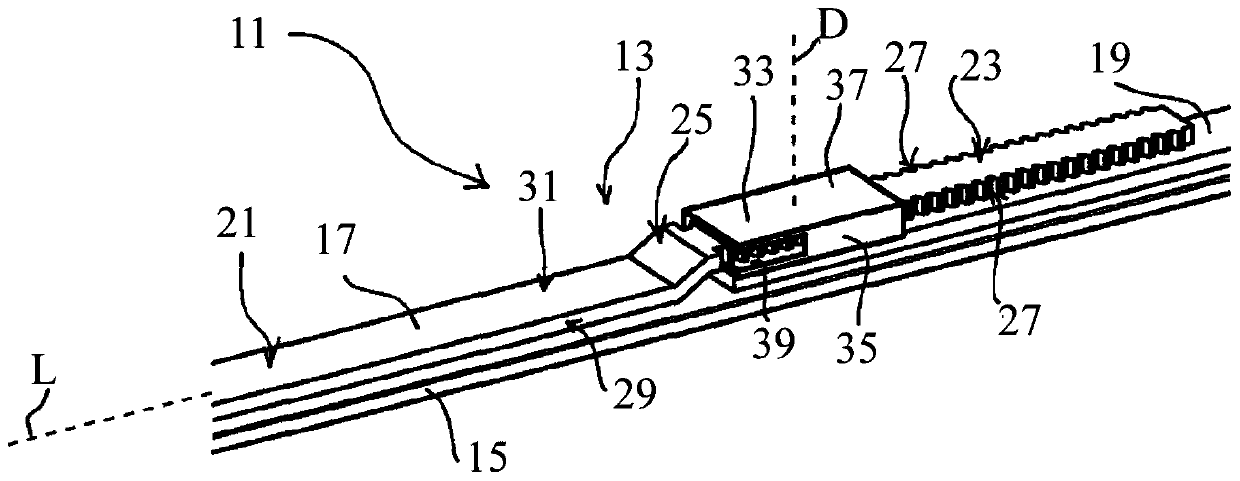

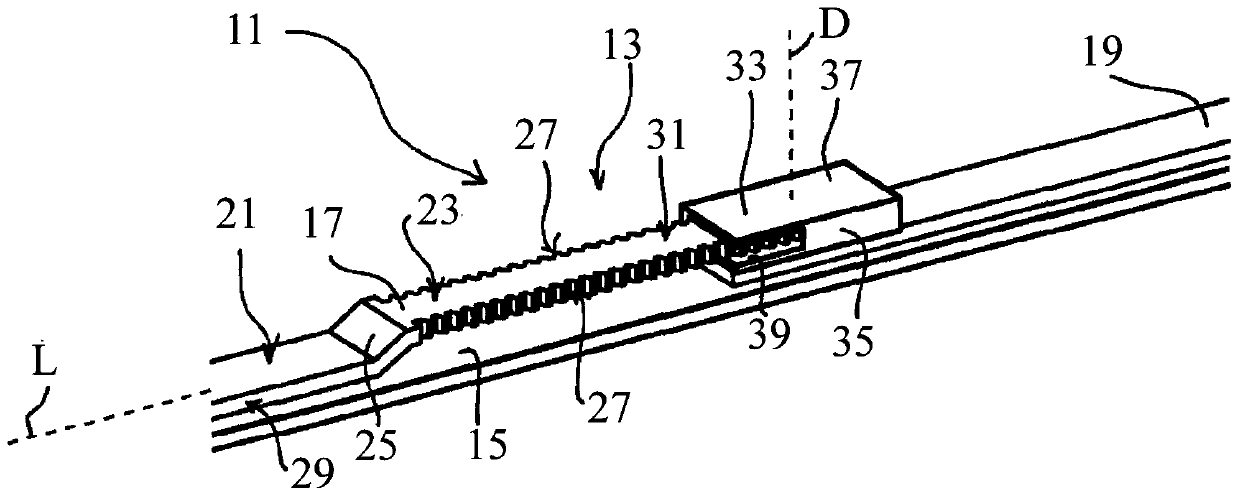

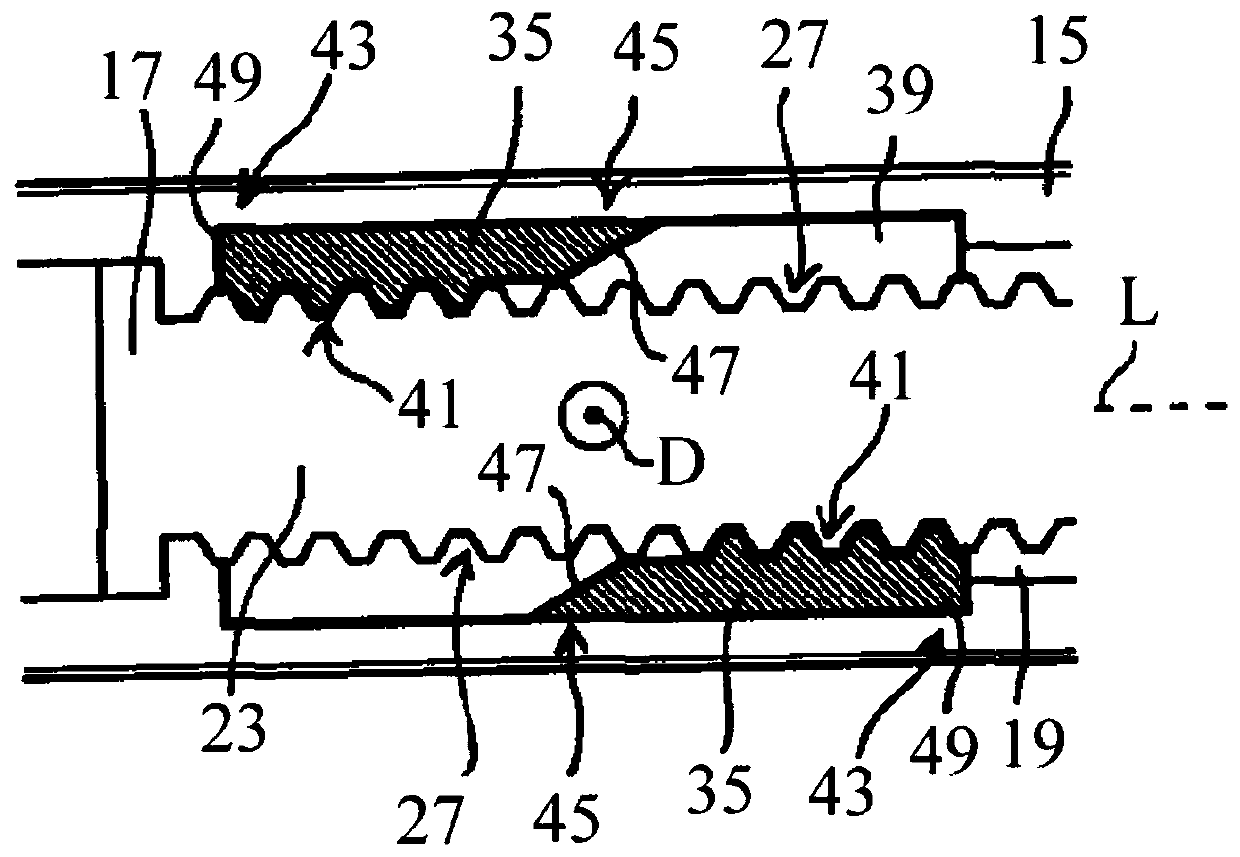

[0043] exist figure 1 An exemplary embodiment of the fitting assembly 11 according to the invention is shown in perspective in the middle. In this case, the fitting assembly 11 is not shown in its entirety, but only a section which illustrates the length adjustability according to the invention. The fitting assembly 11 comprises a locking lever 13 for transmitting an actuating stroke of a drive, not shown, to a different locking element, also not shown. Furthermore, the fitting assembly 11 has a sleeve rail 15 which covers the locking lever 13 when the fitting assembly 11 is inserted into the fitting groove of the door or window.

[0044]By making the locking rod 13 comprise a first sub-rod 17 and a second sub-rod 19, and the first sub-rod 17 and the second sub-rod 19 can move relative to each other along the longitudinal axis L of the locking rod 13, so that the locking rod 13 The length is adjustable. The two sub-rods 17, 19 are designed as elongated and flat rods. The s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap