Method for separating and purifying xylose and arabinose from hemicellulose acid hydrolysis liquid

A technology of hemicellulose and arabinose, applied in the field of simulated moving bed chromatographic separation, can solve the problems such as difficult to effectively control the process, affect industrial production, and uneconomical separation process, achieve less mobile phase consumption, realize continuous operation, The effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

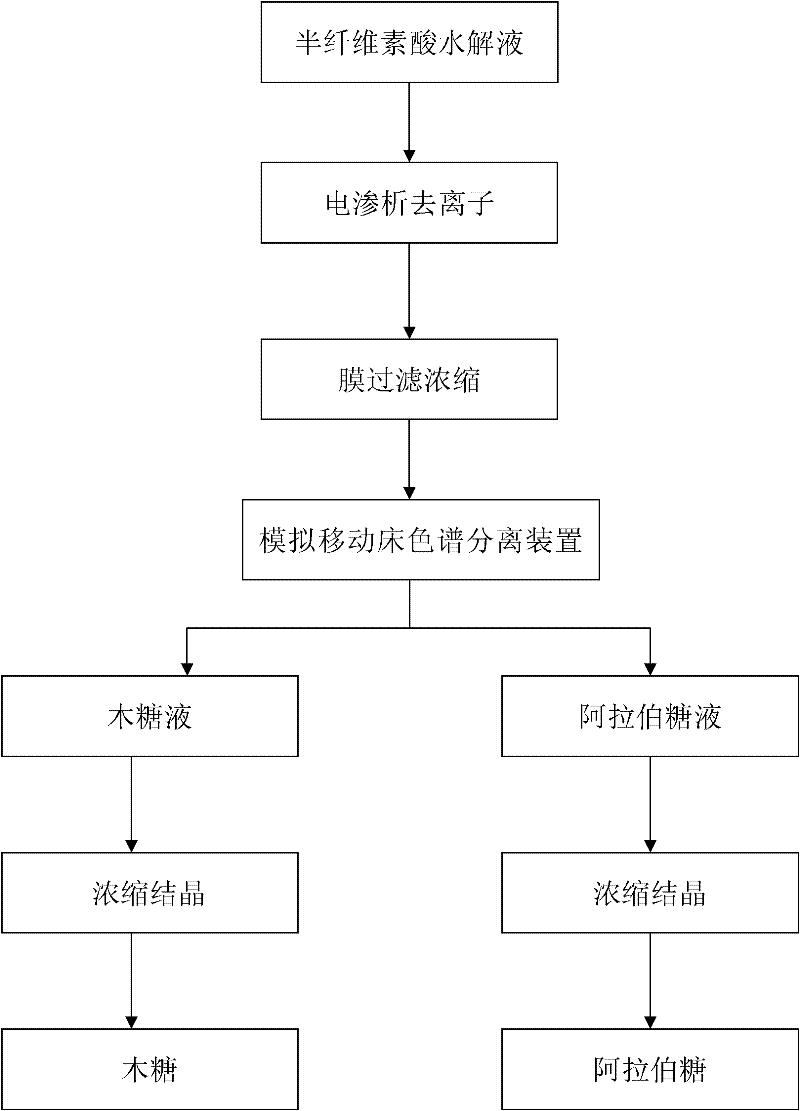

[0026] A method for separating and purifying xylose and arabinose from hemicellulose acid hydrolyzate, the steps are as follows:

[0027] (1) The hemicellulose hydrolyzate directly obtained by acid hydrolysis is subjected to electrodialysis, membrane filtration and concentrated pretreatment, and the measured concentration is 40%. The high-purity water is deoxygenated and filtered for subsequent use, and the composition content of the feed liquid is detected by high-performance liquid chromatography. The xylose content is 75.6%, and the arabinose content is 20.3%;

[0028] The hemicellulose acid hydrolyzate is pretreated by electrodialysis deionization, membrane filtration and concentration, and then enters the simulated moving bed separation as the feed liquid to eliminate interference and achieve high-efficiency separation.

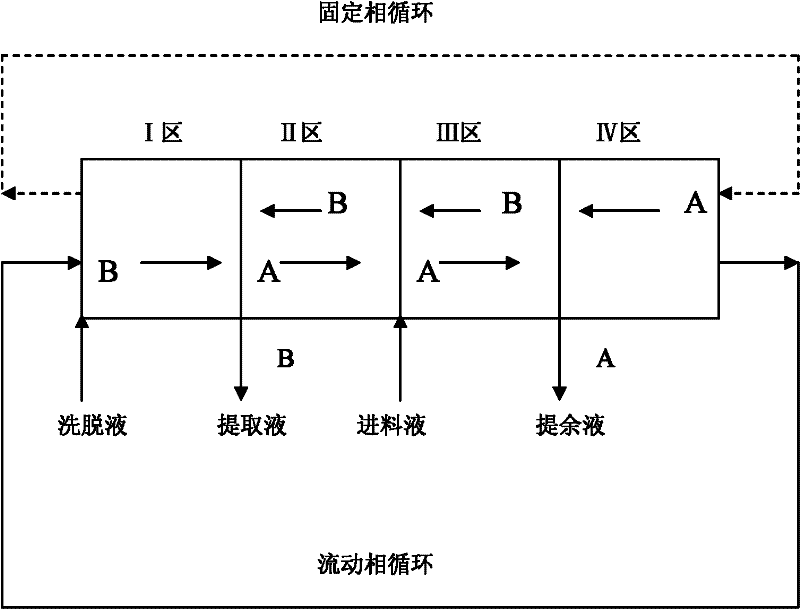

[0029] (2) Start the switch of the column thermostat and the water bath box to make it rise to the set temperature of 70°C, and enter the pretreated raw...

Embodiment 2

[0033] (1) The hemicellulose hydrolyzate directly obtained by acid hydrolysis is subjected to electrodialysis, membrane filtration, concentrated pretreatment, and the measured concentration is 51%, and the high-purity water is deoxygenated and filtered for standby. The composition content of the feed liquid is detected by high performance liquid chromatography, and the content of xylose is 73.4%, and the content of arabinose is 21.8%.

[0034] (2) Start the switch of the column thermostat and the water bath box to raise it to the set temperature of 65°C, and enter the pretreated raw material liquid into the simulated moving bed chromatographic separation device for separation. The process conditions are as follows: maintain a pressure not exceeding 1Mpa Under the premise, the separation temperature is 65°C, the feed rate of the raw material liquid is 145ml / min, and the feed rate of the eluent high-purity water is 180ml / min. After 20 hours of operation, the equilibrium is reache...

Embodiment 3

[0037] (1) The hemicellulose hydrolyzate directly obtained by acid hydrolysis is subjected to electrodialysis, membrane filtration, concentrated pretreatment, and the measured concentration is 60%, and high-purity water is deoxygenated and filtered separately for standby. The composition content of the feed liquid is detected by high performance liquid chromatography, and the content of xylose is 74.6%, and the content of arabinose is 22.3%.

[0038] (2) Start the switch of the column thermostat and the water bath box to make it rise to the set temperature of 70°C, and enter the pretreated raw material liquid into the simulated moving bed chromatographic separation device for separation. Under the premise, the separation temperature is 70°C, the feed rate of the raw material liquid is 155ml / min, and the feed rate of the eluent high-purity water is 220ml / min. After 17 hours of operation, the equilibrium is reached. The conditions of the two output liquids are: one is rich in xyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com