A land covering machine

A laminator and land technology, applied in plant protection cover, horticulture, botanical equipment and methods, etc., can solve the problems of high labor cost, labor and trouble, and achieve the effect of avoiding being blown away by the wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

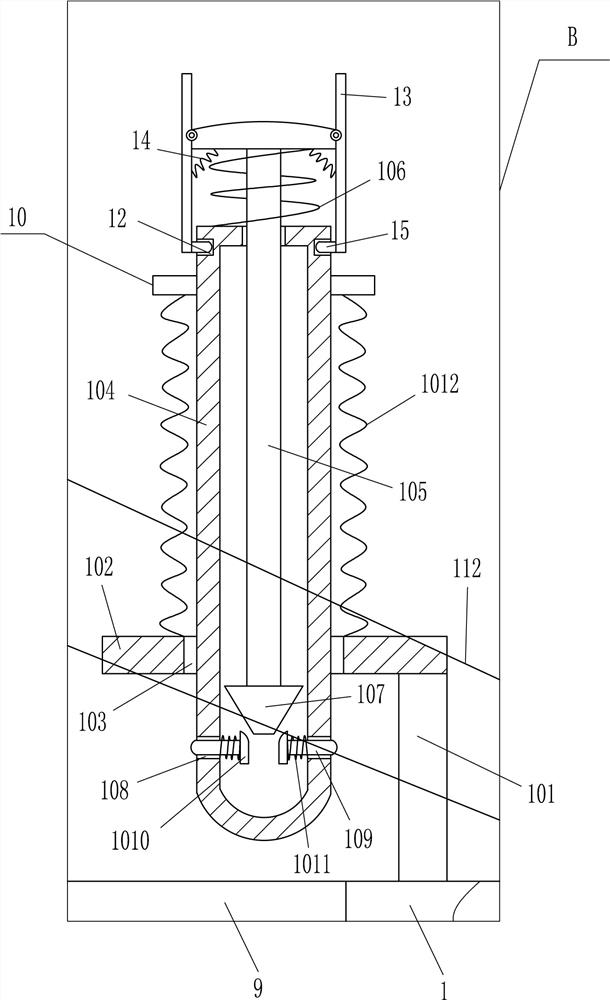

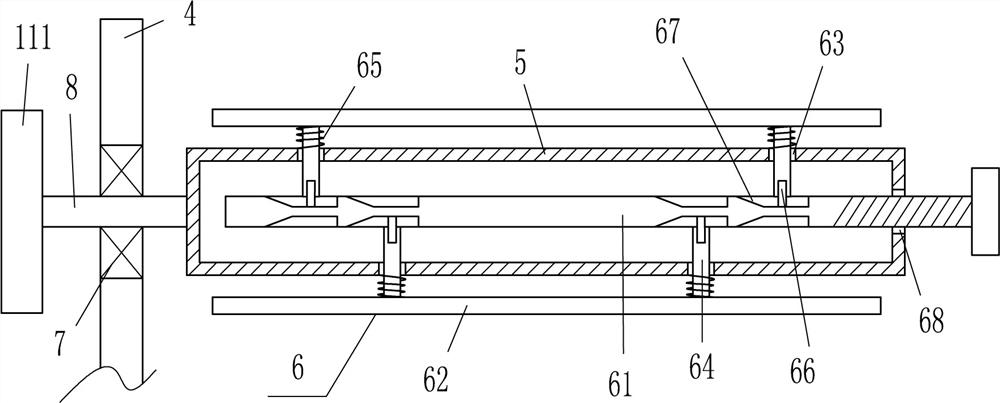

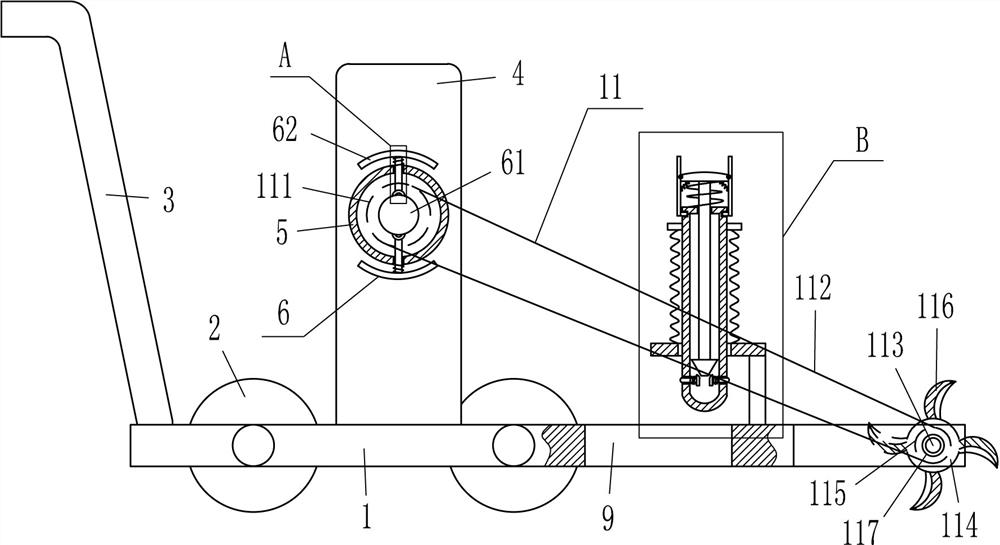

[0021] A land mulching machine such as Figure 1-4 As shown, it includes a base plate 1, wheels 2, pull rods 3, vertical plates 4, cylinder 5, fixing device 6, first bearing seat 7, rotating shaft 8 and pushing device 10, and the left part of the front and rear sides of the base plate 1 is rotating Two wheels 2 are installed, and the tie rod 3 is installed on the left side of the top of the bottom plate 1. The tie rod 3 is connected to the bottom plate 1 by welding. The first bearing seat 7 is installed, the first bearing seat 7 is connected with a rotating shaft 8, the front end of the rotating shaft 8 is fixedly connected with the cylinder body 5, the rotating shaft 8 is connected with the cylinder body 5 by welding, and the cylinder body 5 is equipped with a The fixing device 6 that the plastic film is fixed, the bottom plate 1 right part has the opening 9 that can make the plastic film pass, and the right side of the bottom plate 1 top is provided with a pusher 10 that can...

Embodiment 2

[0023] A land mulching machine such as Figure 1-4 As shown, it includes a base plate 1, wheels 2, pull rods 3, vertical plates 4, cylinder 5, fixing device 6, first bearing seat 7, rotating shaft 8 and pushing device 10, and the left part of the front and rear sides of the base plate 1 is rotating Two wheels 2 are installed, and the pull rod 3 is installed on the left side of the top of the base plate 1. A riser 4 is fixedly connected to the rear part of the top left side of the base plate 1. A first bearing seat 7 is embedded in the middle of the upper part of the riser 4. The first bearing The seat 7 is connected with a rotating shaft 8, the front end of the rotating shaft 8 is fixedly connected with a cylinder 5, the cylinder 5 is provided with a fixing device 6 for fixing the plastic film, and the right part of the base plate 1 has an opening 9 through which the plastic film can pass. The right side of the bottom plate 1 top is provided with a propulsion device 10 that ca...

Embodiment 3

[0026] A land mulching machine such as Figure 1-4As shown, it includes a base plate 1, wheels 2, pull rods 3, vertical plates 4, cylinder 5, fixing device 6, first bearing seat 7, rotating shaft 8 and pushing device 10, and the left part of the front and rear sides of the base plate 1 is rotating Two wheels 2 are installed, and the pull rod 3 is installed on the left side of the top of the base plate 1. A riser 4 is fixedly connected to the rear part of the top left side of the base plate 1. A first bearing seat 7 is embedded in the middle of the upper part of the riser 4. The first bearing The seat 7 is connected with a rotating shaft 8, the front end of the rotating shaft 8 is fixedly connected with a cylinder 5, the cylinder 5 is provided with a fixing device 6 for fixing the plastic film, and the right part of the base plate 1 has an opening 9 through which the plastic film can pass. The right side of the top of the base plate 1 is provided with a propulsion device 10 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com