Intelligent plastic film mulching machine

A technology of plastic film covering and fixed frame, which is applied in plant protection cover, metal processing, gardening, etc. It can solve the problems of easy slipping, inconvenient rotation of the bottom wheel, and inconvenient adjustment of the scraping frame, etc., to increase the anti-slip effect and increase the grip The effect of soil force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

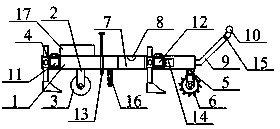

[0038] as attached figure 1 And attached Figure 4 shown

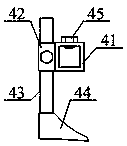

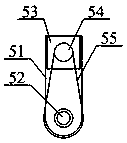

[0039]The invention provides an intelligent mulching machine, which includes a back-shaped fixed frame 1, a rear wheel frame 2, a rear wheel 3, an adjustable scraping frame structure 4, a front driving frame structure 5, a removable movable frame structure 6, and a side Fixed frame 7, concave groove 8, guide rod 9, handle 10, rear side fixed mount 11, front side fixed mount 12, auxiliary cutting frame structure 13, controller 14, power switch 15, buffer guide frame structure 16 and can Rechargeable lithium battery 17, the rear wheel frame 2 is welded on the front and rear sides of the middle and lower part of the back-shaped fixed frame 1; the rear wheel 3 shaft is connected to the bottom of the rear wheel frame 2; the adjustable scraper The frame structure 4 is respectively installed on the front and rear sides of the rear side fixed frame 11 and the front side fixed frame 12; Remove the mobile frame structure 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com