Self-adaptive pavement liquid speed bump

A self-adaptive, speed bump technology, applied in the directions of roads, roads, road signs, etc., can solve the problems of poor adaptability of speed bumps, the influence of vibration, and the inability to distinguish between rewards and punishments, so as to prevent rear-end collision accidents and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

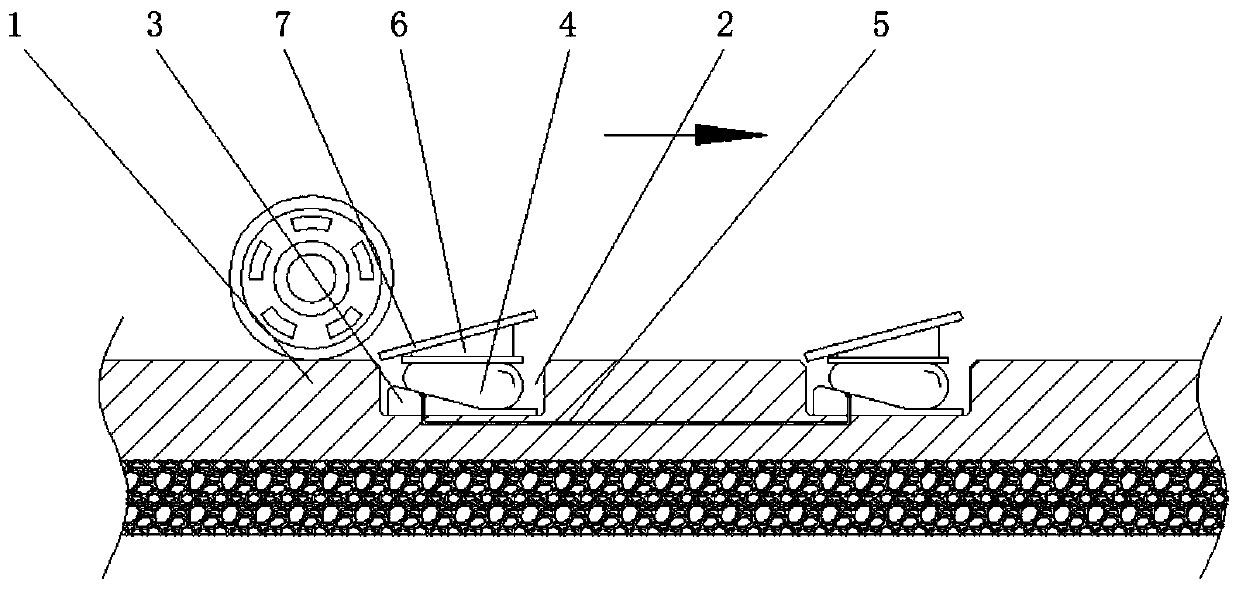

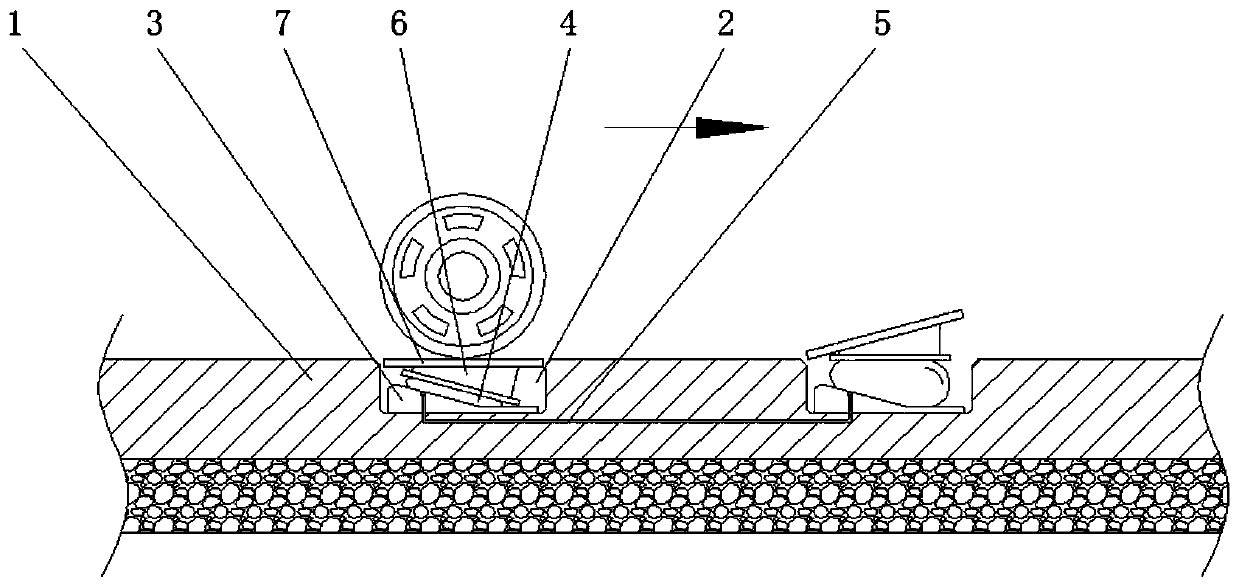

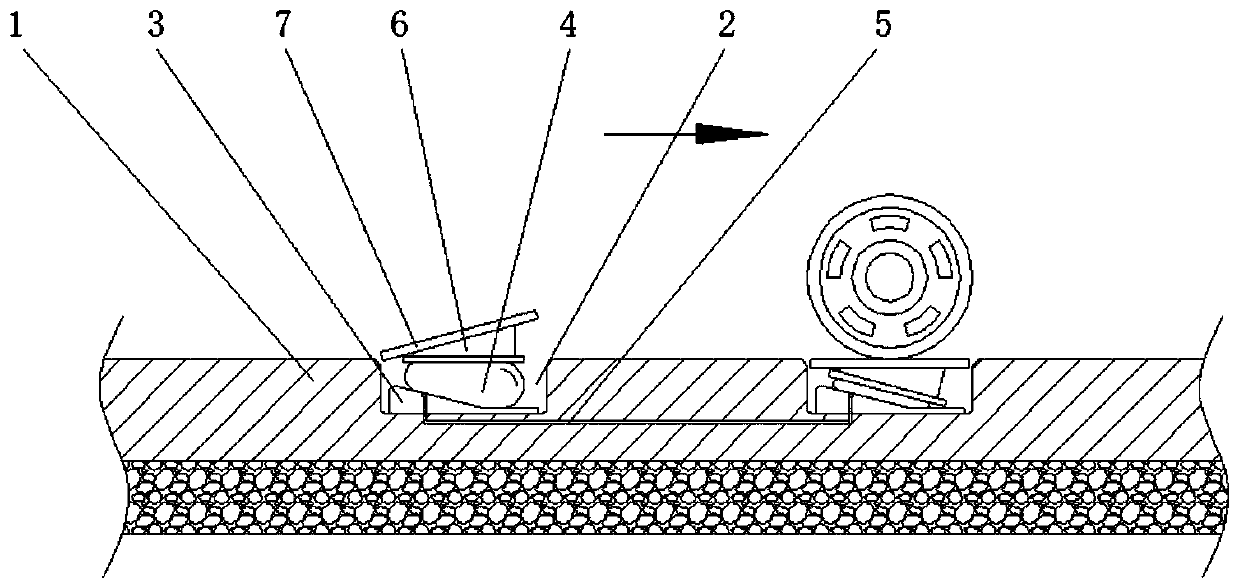

[0027] When the vehicle speed is fast, the pressure time for the pressure-bearing sealing bag 4 will be shorter, so that the hydraulic transmission oil in it cannot be compressed into another group of pressure-bearing sealing bags 4 in time and effectively, thereby causing the deceleration pressure plate 7 The inclination height is difficult to occur, and then the resistance to the vehicle is relatively large, and when the vehicle speed is slow, the pressure time for the pressure-bearing sealing bag 4 is relatively long, so that the hydraulic transmission oil in the pressure-bearing sealing bag 4 is sufficient. The time is compressed into the next group of pressure-bearing sealed capsules 4, which in turn causes the inclination angle of the deceleration plate 7 to be reduced, without forming a large hindering force on the vehicle, so that the deceleration belt can be used for vehicles with different speeds. Form the hindering force of different sizes, for example, take the exis...

specific Embodiment 2

[0031] When the front vehicle drives the front deceleration plate 7 at a lower speed, and prepares to pass through the rear deceleration plate 7 at the same speed, the hydraulic transmission in the pressure sealing bag 4 will be compressed under the pressure of the front vehicle. transported to another group of pressure-bearing sealing bags 4, so that the pressure on the pressure-bearing sealing bags 4 and the deceleration plate 7 is relatively large and difficult to be compressed, resulting in greater obstruction and vibration, and then forcing the vehicles behind to have to Continue to decelerate and wait for the vehicle in front to pass, or pass the speed reduction belt at a lower speed, resulting in an increase in the distance between the front and rear vehicles, effectively improving the safety of the vehicle when passing the speed reduction belt, and preventing the rear vehicle from over-decelerating When the speed is fast, there will be a rear-end collision with the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com