Experimental model of shield tunnel segment joints with different stiffnesses under the action of positive and negative bending moments

A technology of shield tunnel segment and test model, which is applied in tunnels, teaching models, tunnel linings, etc., can solve the problem that the different stiffness of segment joints cannot be considered, and avoid assembly work, with strong practicability and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

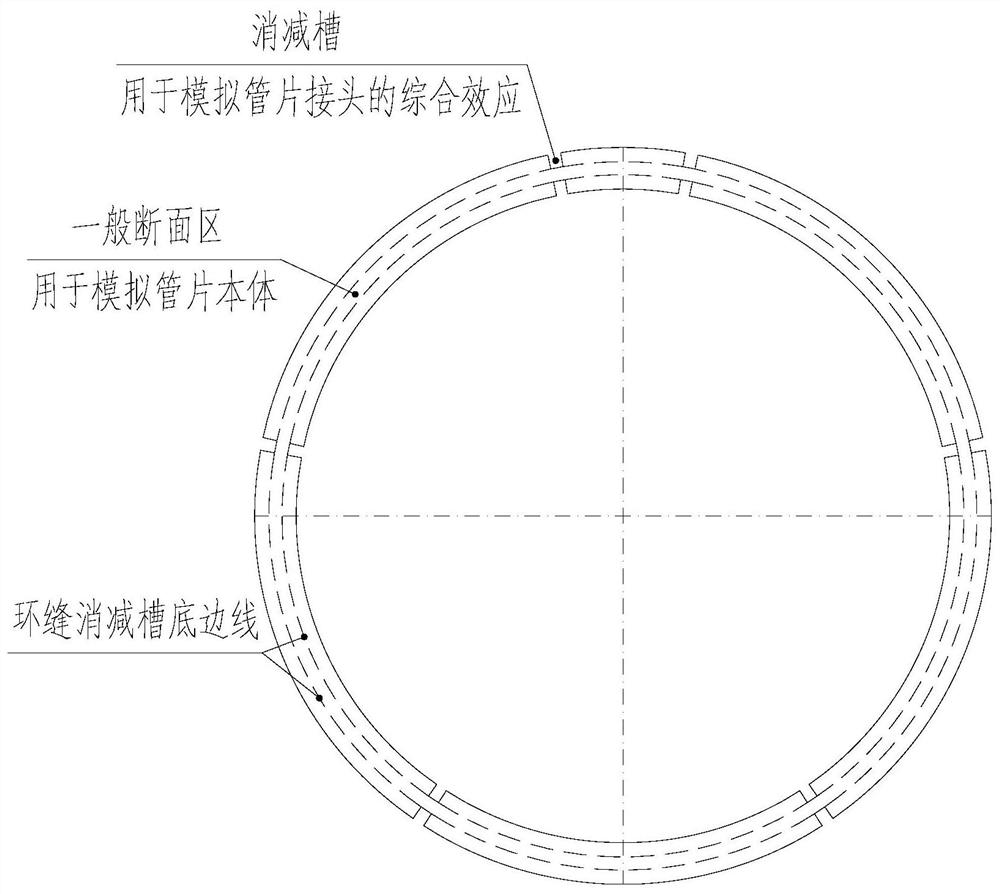

[0026] Such as Figure 1-4 As shown, the present invention provides a shield tunnel segment joint test model with different rigidities under the action of positive and negative bending moments, which is used to truly simulate the segment joint prototype model in the model test.

[0027] The shield tunnel segment joint test model includes:

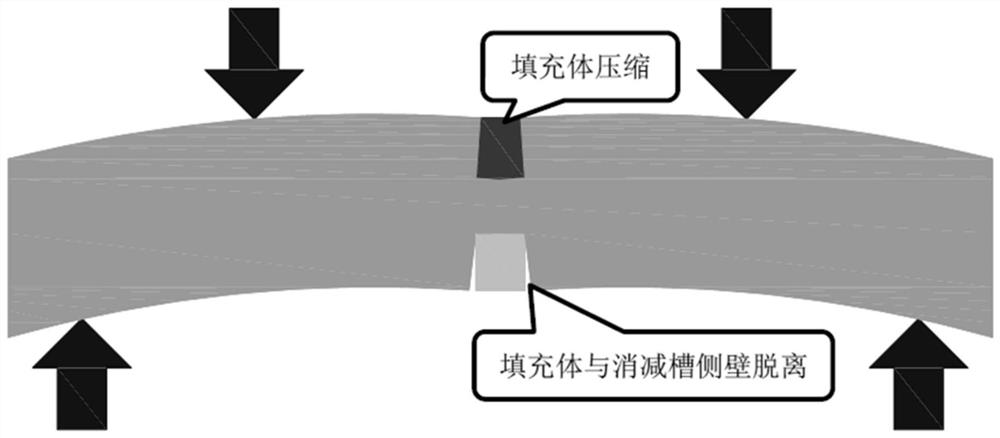

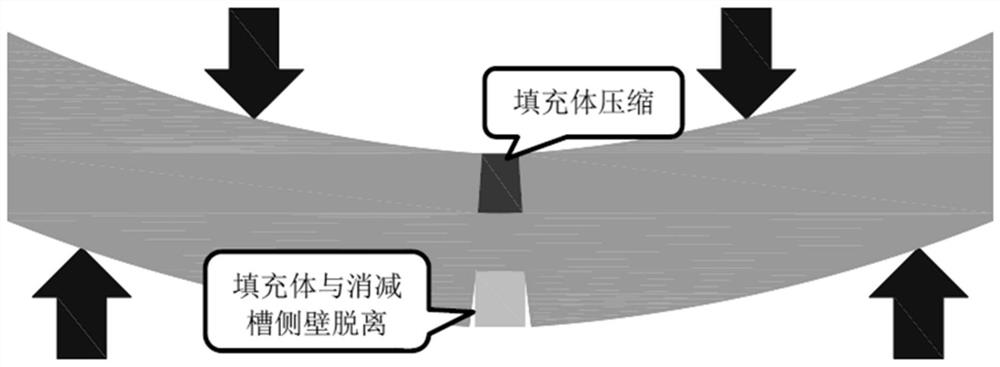

[0028] Segment body 1 and a plurality of reducing grooves provided on the inner and outer surfaces of the segment body 1, the reducing grooves include annular seam reducing groove 2 and longitudinal seam reducing groove 3, and each circular seam reducing groove 2 and longitudinal seam reducing groove Filling bodies 4 are provided in the grooves 3, and the filling bodies 4 are only under pressure, and are disengaged from the side walls of the reducing grooves when subjected to tension, so as to realize different rigidities of the inner and outer surfaces of the segment body 1 .

[0029] The shield tunnel segment joint test model is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com