Free-form surface measurement method and device for correcting pose based on reference calibration plate

A measurement method and calibration board technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of rotary table rotation error, mechanical arm space motion error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

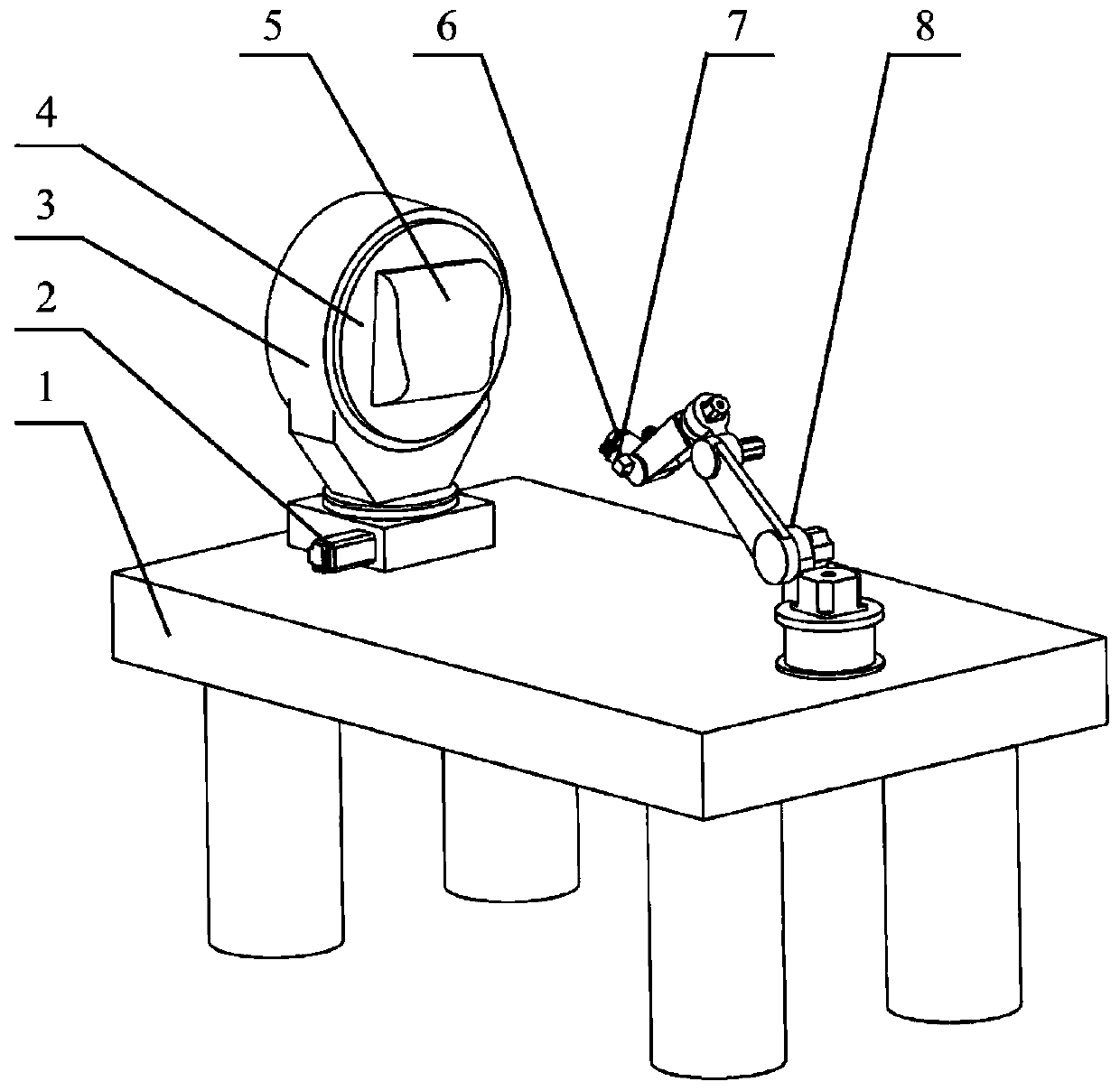

[0025] Such as figure 1 As shown, the free-form surface measurement method and device based on the error correction of the reference calibration plate of the present invention specifically includes the following steps:

[0026] Step 1: Install the free-form surface measurement sensor 6 in the center of the end effector of the mechanical arm 8, install the reference calibration plate camera 7 on both sides of the end effector of the mechanical arm 8, and measure the free-form surface measurement sensor 6 and reference calibration through the laser tracker The pose between the board cameras 7 is calculated to obtain the transformation matrix of the benchmark calibration board camera 7 relative to the free-form surface measurement sensor 6;

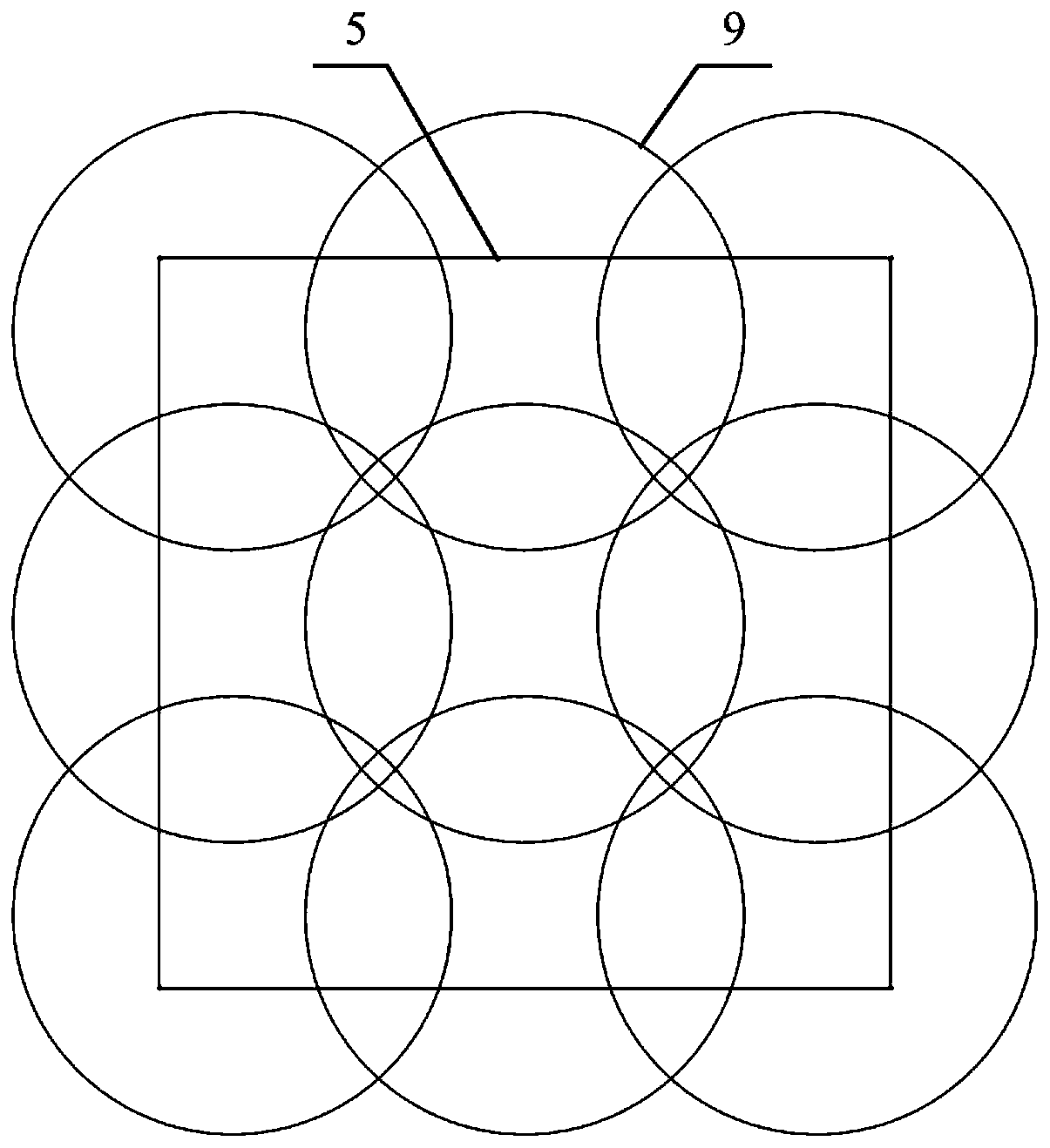

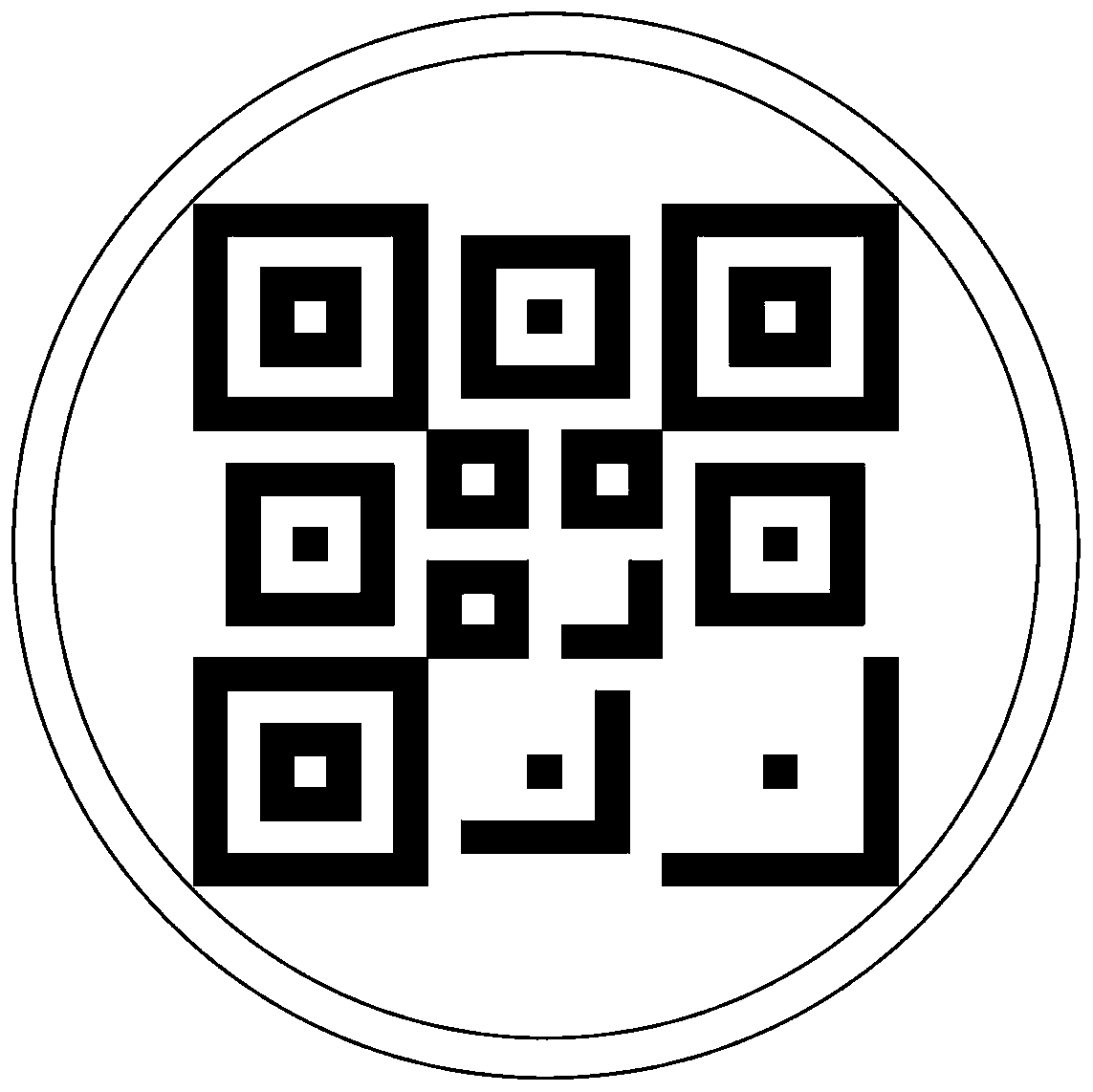

[0027] Step 2: Install the high-precision reference calibration plate 4 on the rotary table 3, and fix the measured free-form surface 5 on the surface of the reference calibration plate 4, and install the rotary table 3 and the mechanical ar...

Embodiment 2

[0033] Such as figure 1 and figure 2As shown, the free-form surface measurement method and device based on the error correction of the reference calibration plate of the present invention specifically includes the following steps:

[0034] Step 1: Install the free-form surface measurement sensor 6 in the center of the end effector of the mechanical arm 8, install the reference calibration plate camera 7 on both sides of the end effector of the mechanical arm 8, and measure the free-form surface measurement sensor 6 and reference calibration through the laser tracker The pose between the board cameras 7 is calculated to obtain the transformation matrix of the benchmark calibration board camera 7 relative to the free-form surface measurement sensor 6;

[0035] Step 2: Install the high-precision reference calibration plate 4 on the rotary table 3, and fix the measured free-form surface 5 on the surface of the reference calibration plate 4, and install the rotary table 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com