Device capable of quickly covering centrifugal tube

A centrifuge tube and cover technology, which is applied in the field of medical supplies, can solve the problems of affecting the operation effect, increasing the workload of the staff, and the cover is loose, so as to achieve the effect of improving the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

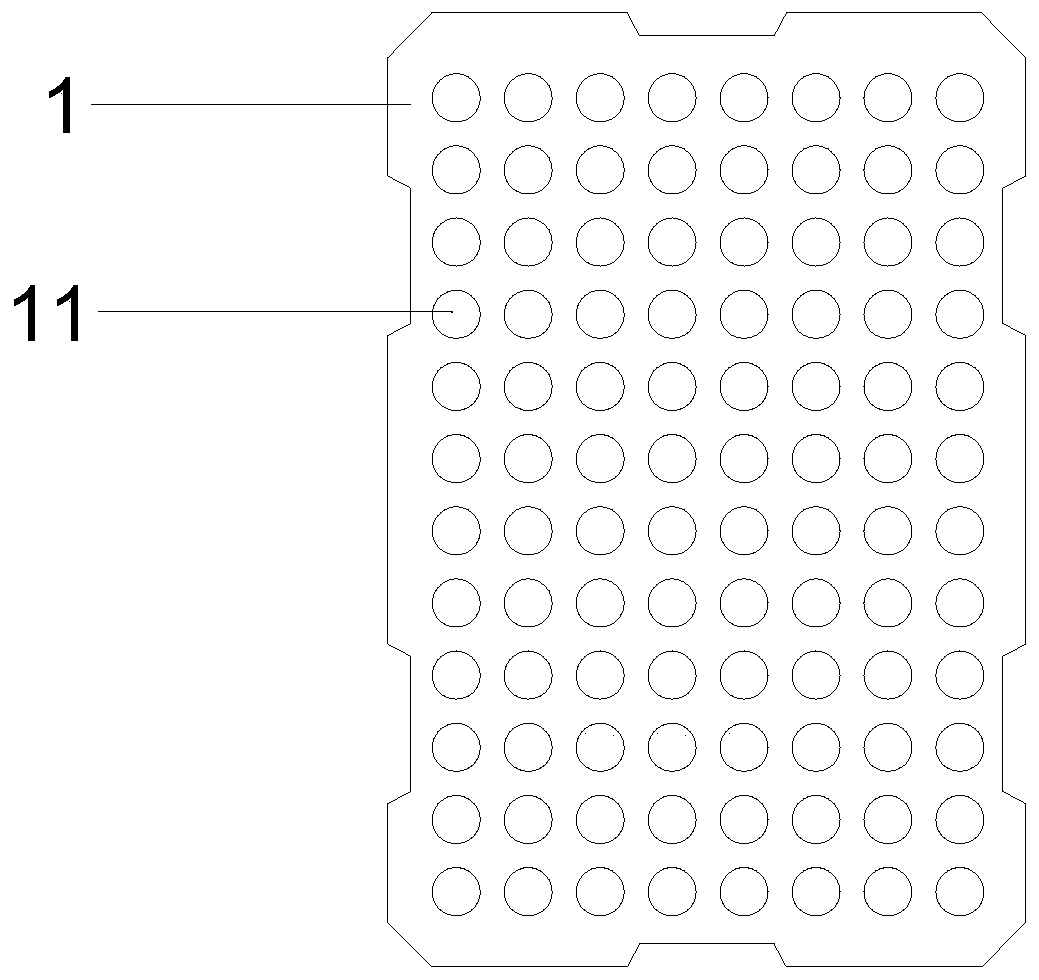

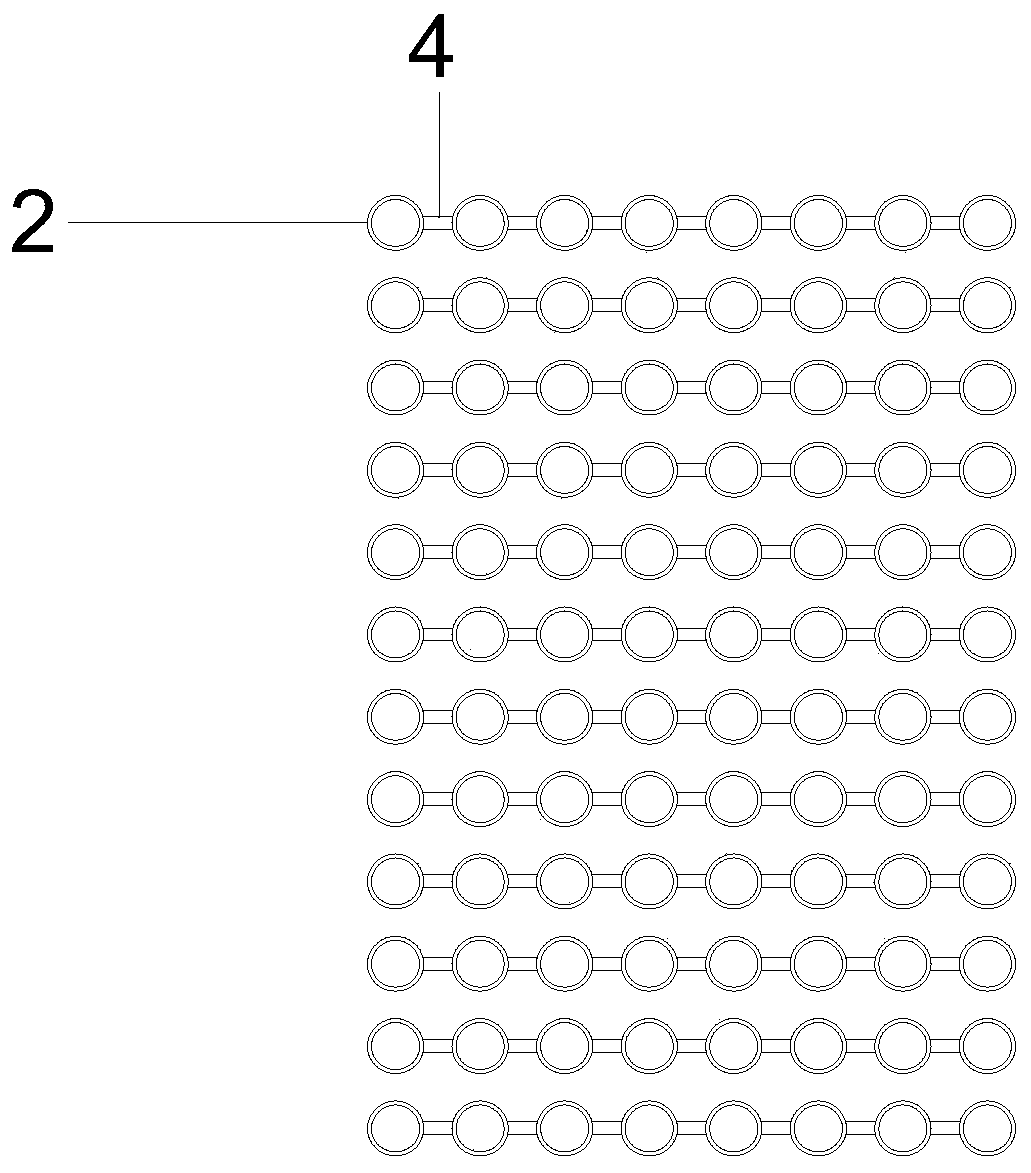

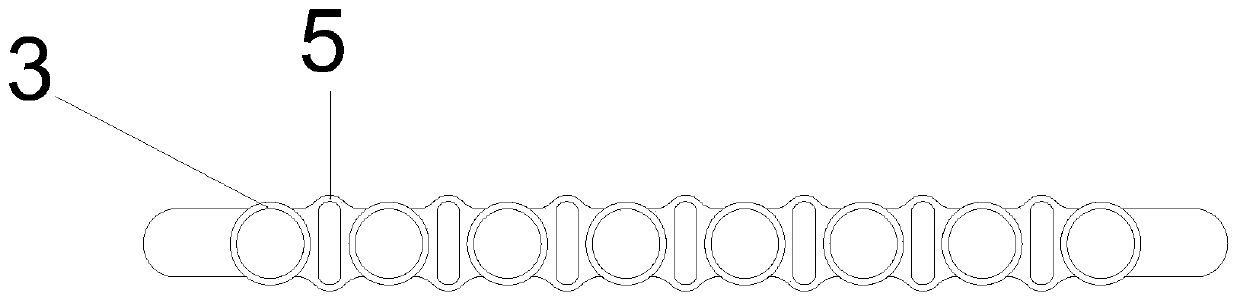

[0033] Embodiment 1: The pressing teeth on the pressure plate of the mechanical capping and pressing device are distributed as 8 in a row, and 8 centrifuge tube caps can be capped and pressed at one time;

Embodiment 2

[0034] Embodiment 2: The pressing teeth on the pressure plate of the mechanical cover pressing device are distributed as 8*12, and there are 96 pressing teeth in total. When the 96-orifice plate is completely filled with centrifuge tubes, all the covers of 96 centrifuge tubes can be removed at one time. Cover and press well;

[0035] The specific operation method is to place the 96-hole plate of the centrifuge tube in the fixed base of the 96-hole plate of the mechanical capping and pressing device, place the centrifuge tube in the 96-hole plate, put the cap on the nozzle of the centrifuge tube, and start the mechanical capping and pressing device, the pressure plate is pressed down, and the cover of the centrifuge tube is pressed tightly.

[0036] To sum up, the traditional centrifuge tubes need to cover the centrifuge tubes one by one during operation, which is very time-consuming and laborious, and it is easy to cause the cover to loosen during the centrifugation process in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com