A kind of car engine rotary valve

A technology for automobile engines and rotary valves, which is applied to engine components, machines/engines, valve devices, etc., to achieve the effects of reducing sealing problems, regular rotation cycles, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

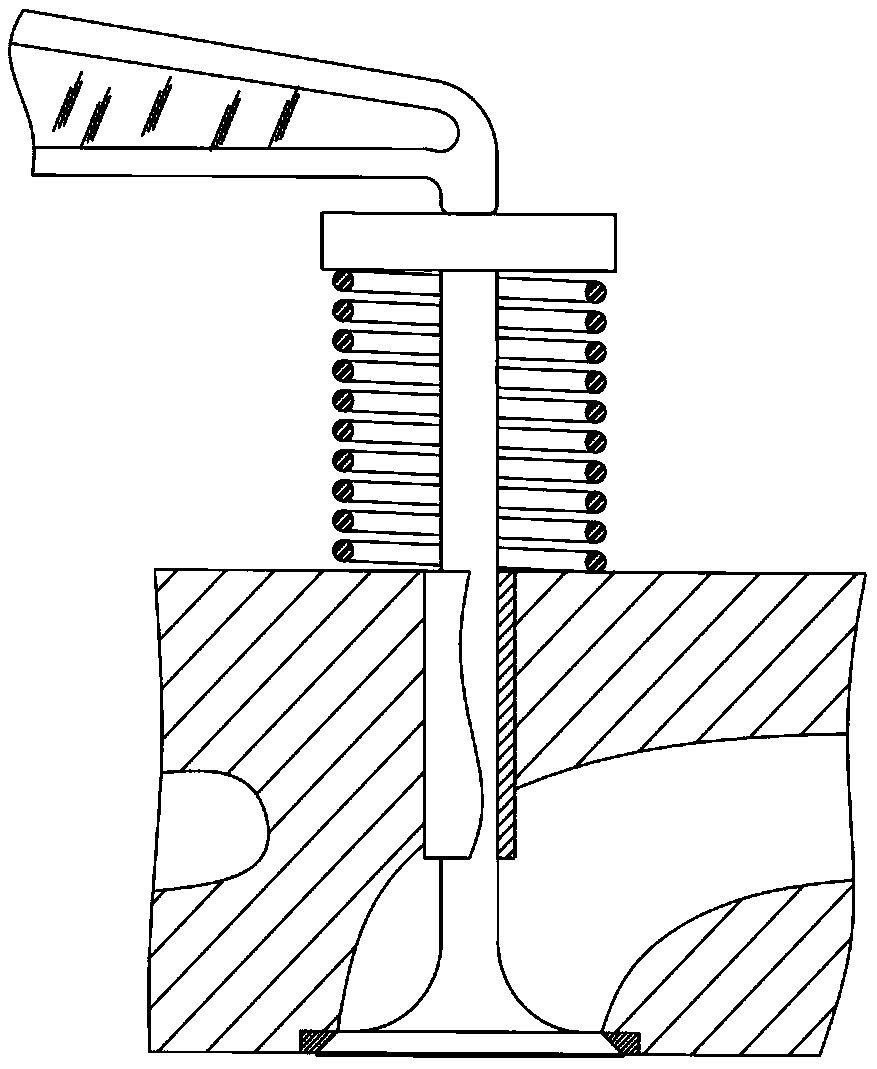

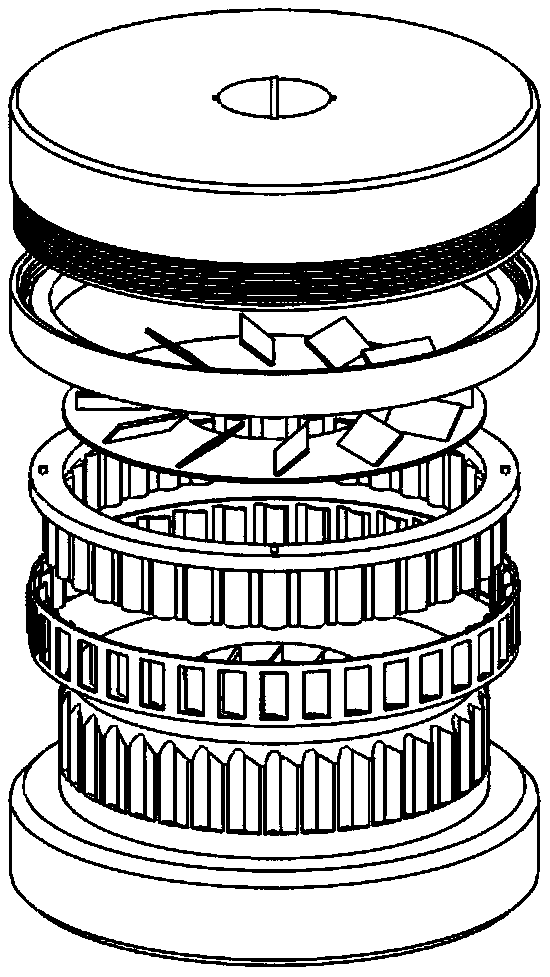

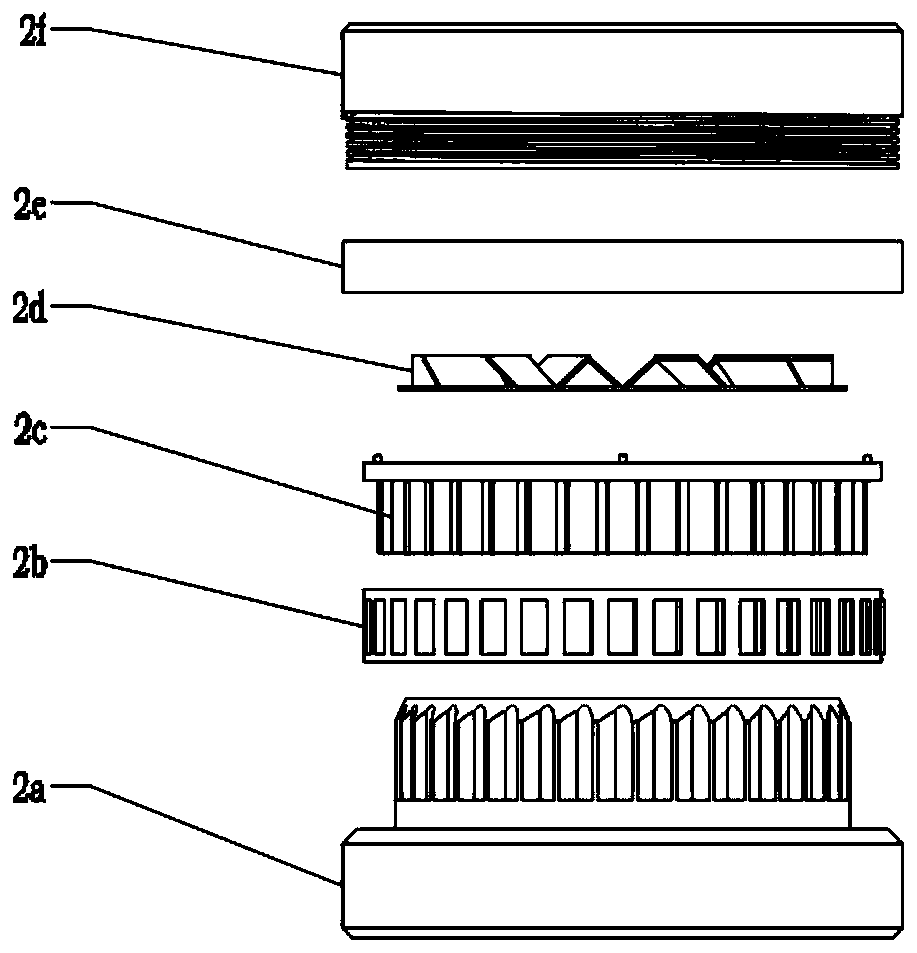

[0038] refer to Figure 2-Figure 4 , the automobile engine valve device 2 of the present embodiment includes a spring seat 2a, an annular circlip 2b, a cylindrical roller cage 2c, a rotary compression spring 2d, a lock cover 2e and a screw cover 2f from bottom to top.

[0039] refer to Figure 5-Figure 6 , the bottom of the spring seat 2a is recessed to form a housing portion 2a8 for the valve spring; the upper part of the spring seat 2a is provided with a boss 2a2 that cooperates with the cylindrical roller cage 2c, the annular circlip 2b and the screw cap 2f. The outer peripheral surface of the boss 2a2 is provided with a ring of accommodating grooves 2a1 for accommodating part of the cylindrical rollers 2c1. The edges of the adjacent accommodating grooves 2a1 are preferably continuous without gaps. Moreover, transitions should be provided in the accommodating grooves 2a1. section 2a7, so that when the cylindrical roller 2c1 moves to the transition section 2a7, it will slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com