Detachable standard connecting piece for door and window outer frame and auxiliary frame

A detachable, connecting piece technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of long installation time, low efficiency, unable to fully realize standardized operation, etc., and achieve the effect of preventing rotation and simplifying the installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

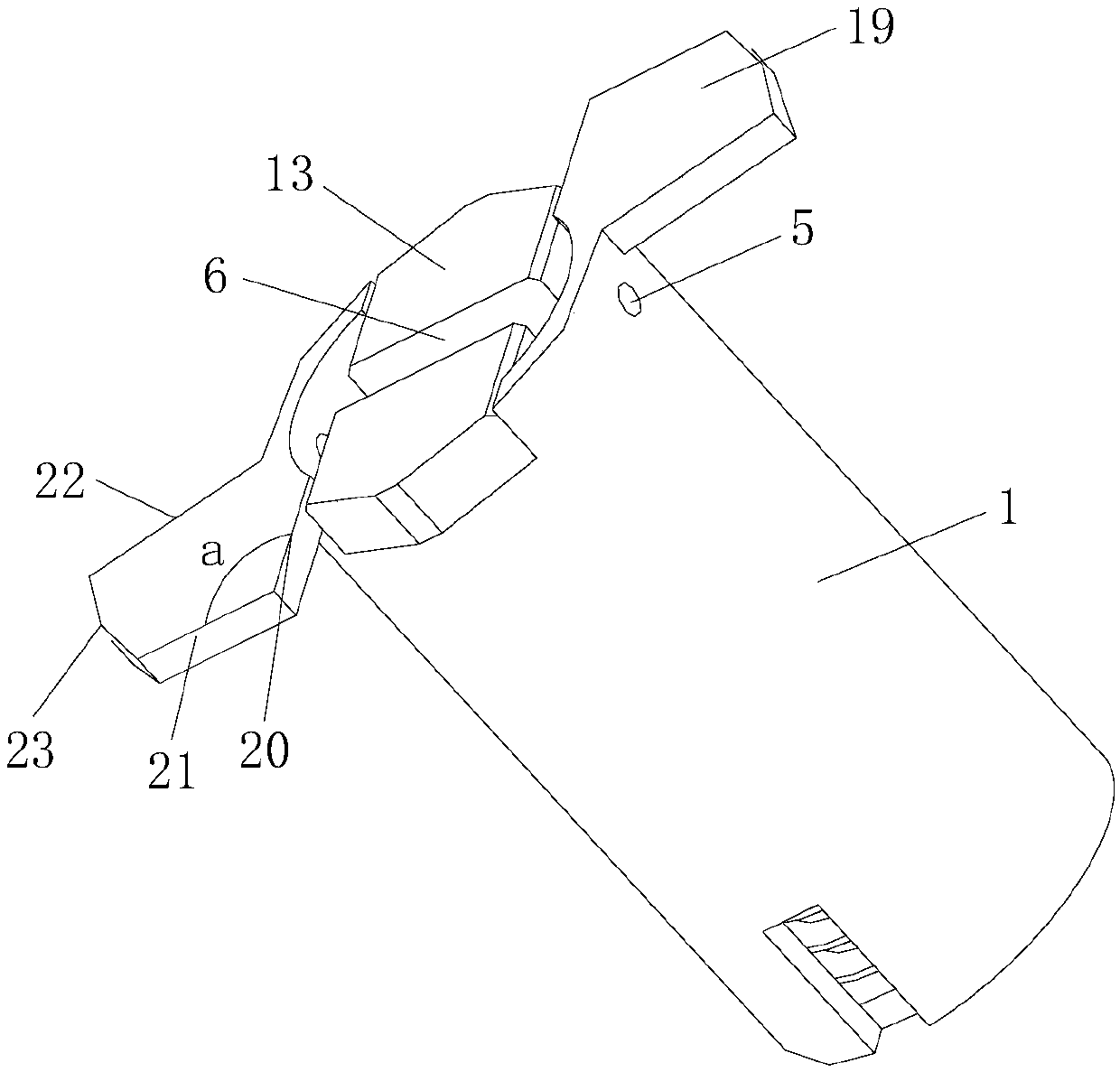

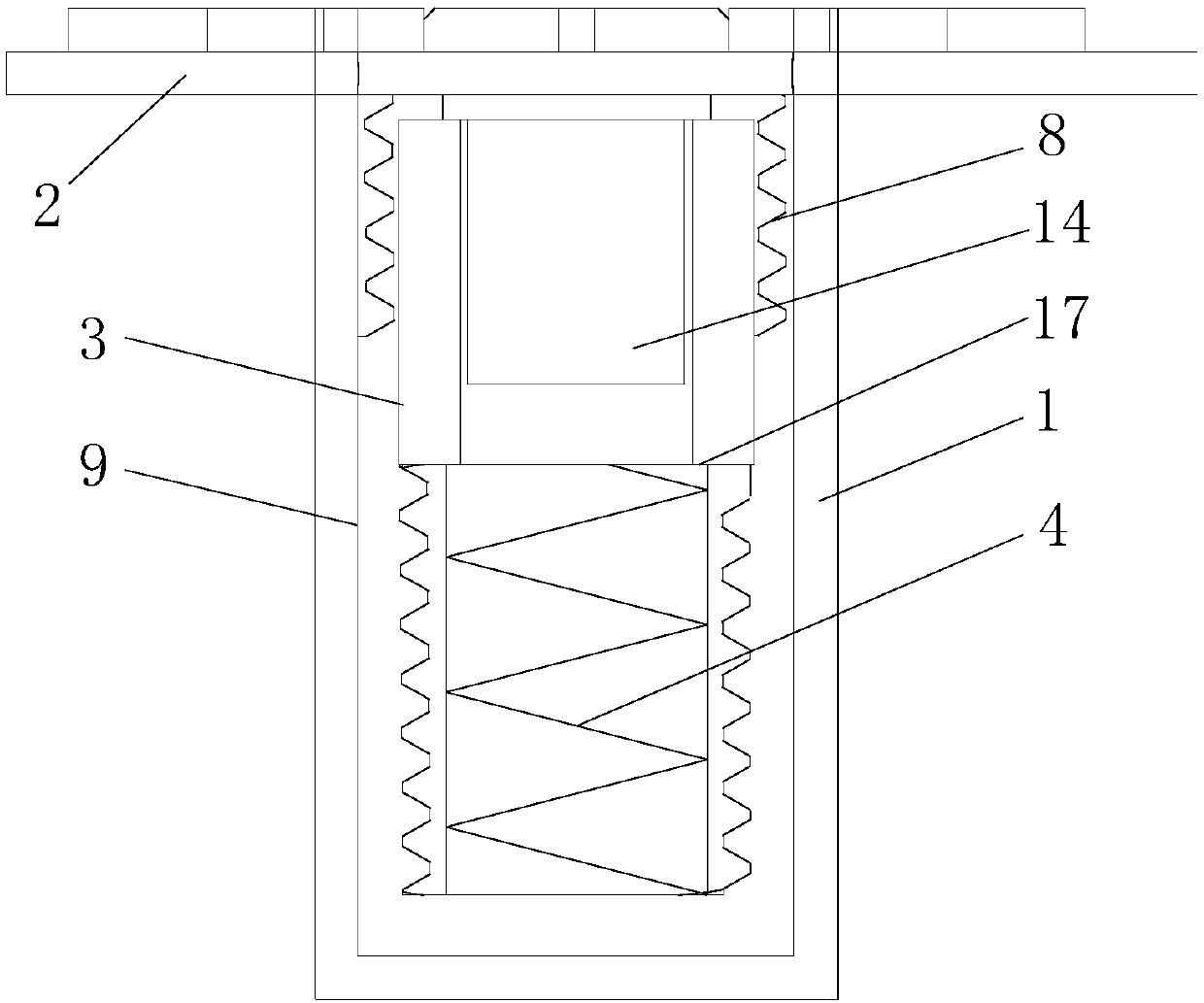

[0032] See Figure 1 to Figure 4 , the present invention has a shaft sleeve 1, a positioning pin 2 and an inner shaft 3; a spring 4 is provided at the bottom end of the inner cavity of the shaft sleeve 1, and a pair of through holes 5 are provided at the opening position of the upper part; an inner shaft 3 is connected to the upper part of the spring 4; The top of the shaft 3 has a slot 6 corresponding to the through hole 5, and the inner shaft 3 is fixed inside the shaft sleeve 1 through the positioning pin 2 inserted in the through hole 5 of the shaft sleeve 1, and the top of the inner shaft 3 is aligned with the shaft sleeve. 1. The end face of the opening end is flush; the inner shaft 3 has an inner shaft external thread 7 on the lower circumference surface; The surface is glossy 9.

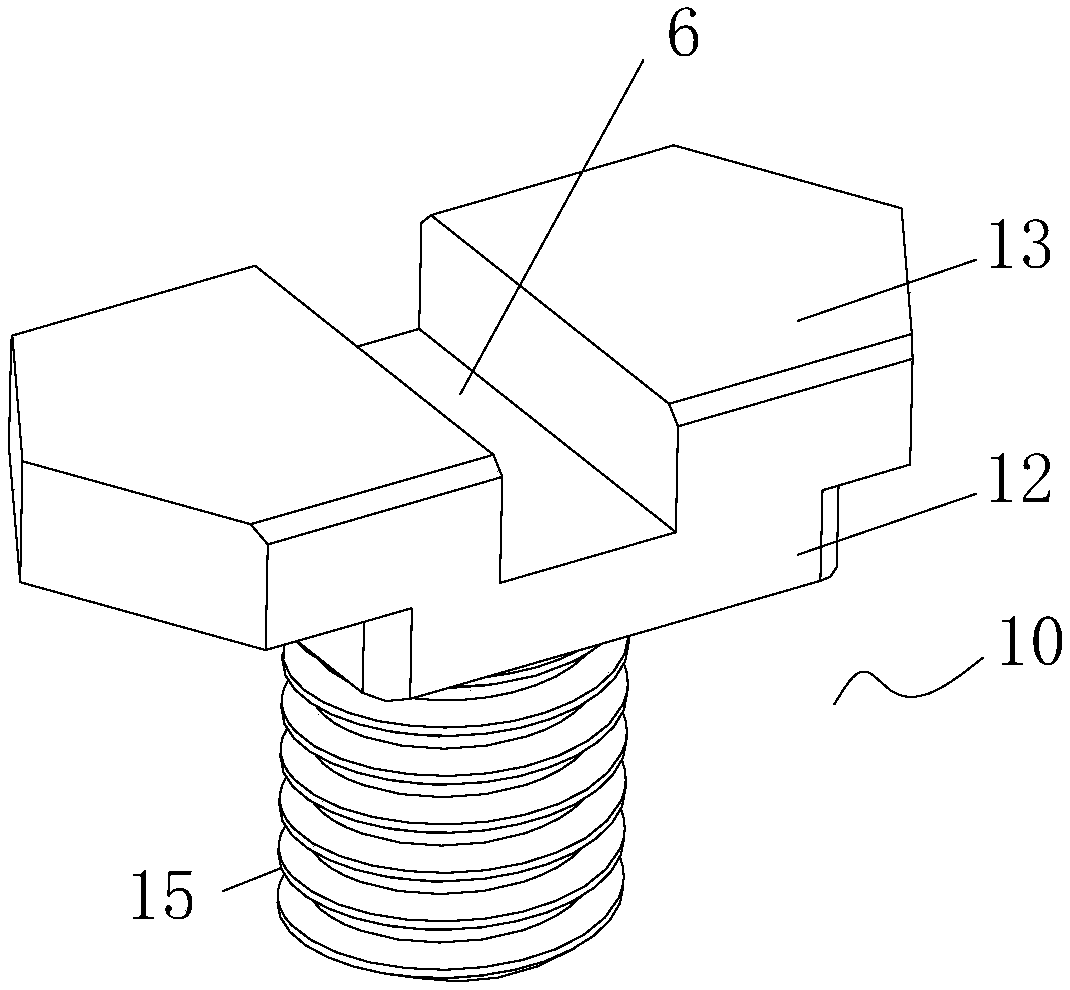

[0033] See Figure 10 , the inner shaft 3 is an up-and-down structure, which is divided into an inner shaft upper body 10 and an inner shaft lower body 11; the inner shaft upper body 10 and...

Embodiment 2

[0038] See Figure 5 and Image 6 , the present invention has a shaft sleeve 1, a positioning pin 2 and an inner shaft 3; a spring 4 is provided at the bottom end of the inner cavity of the shaft sleeve 1, and a pair of through holes 5 are provided at the opening position of the upper part; an inner shaft 3 is connected to the upper part of the spring 4; The top of the shaft 3 has a slot 6 corresponding to the through hole 5, and the inner shaft 3 is fixed inside the shaft sleeve 1 through the positioning pin 2 inserted in the through hole 5 of the shaft sleeve 1, and the top of the inner shaft 3 is aligned with the shaft sleeve. 1. The end face of the opening end is flush; the inner shaft 3 has an inner shaft external thread 7 on the lower circumference surface; The surface is glossy 9.

[0039] See image 3 , Figure 4 and Figure 9 , the inner shaft 3 is a combined upper and lower body, which is divided into an inner shaft upper body 10 and an inner shaft lower body 11...

Embodiment 3

[0042] See Figure 1 to Figure 4, the present invention has a shaft sleeve 1, a positioning pin 2 and an inner shaft 3; a spring 4 is provided at the bottom end of the inner cavity of the shaft sleeve 1, and a pair of through holes 5 are provided at the opening position of the upper part; an inner shaft 3 is connected to the upper part of the spring 4; The top of the shaft 3 has a slot 6 corresponding to the through hole 5, and the inner shaft 3 is fixed inside the shaft sleeve 1 through the positioning pin 2 inserted in the through hole 5 of the shaft sleeve 1, and the top of the inner shaft 3 is aligned with the shaft sleeve. 1. The end face of the opening end is flush; the inner shaft 3 has an inner shaft external thread 7 on the lower circumference surface; The surface is glossy 9.

[0043] See image 3 , Figure 4 and Figure 9 , the inner shaft 3 is a combined upper and lower body, which is divided into an inner shaft upper body 10 and an inner shaft lower body 11; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com