Genetically engineered bacterium producing R-(+)-perillyl alcohol, and construction method and application of genetically engineered bacterium

A technology of genetically engineered bacteria and perillyl alcohol, applied in the fields of genetic engineering and fermentation engineering, can solve the problems of long production cycle and high cost, and achieve the effect of wide living environment and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

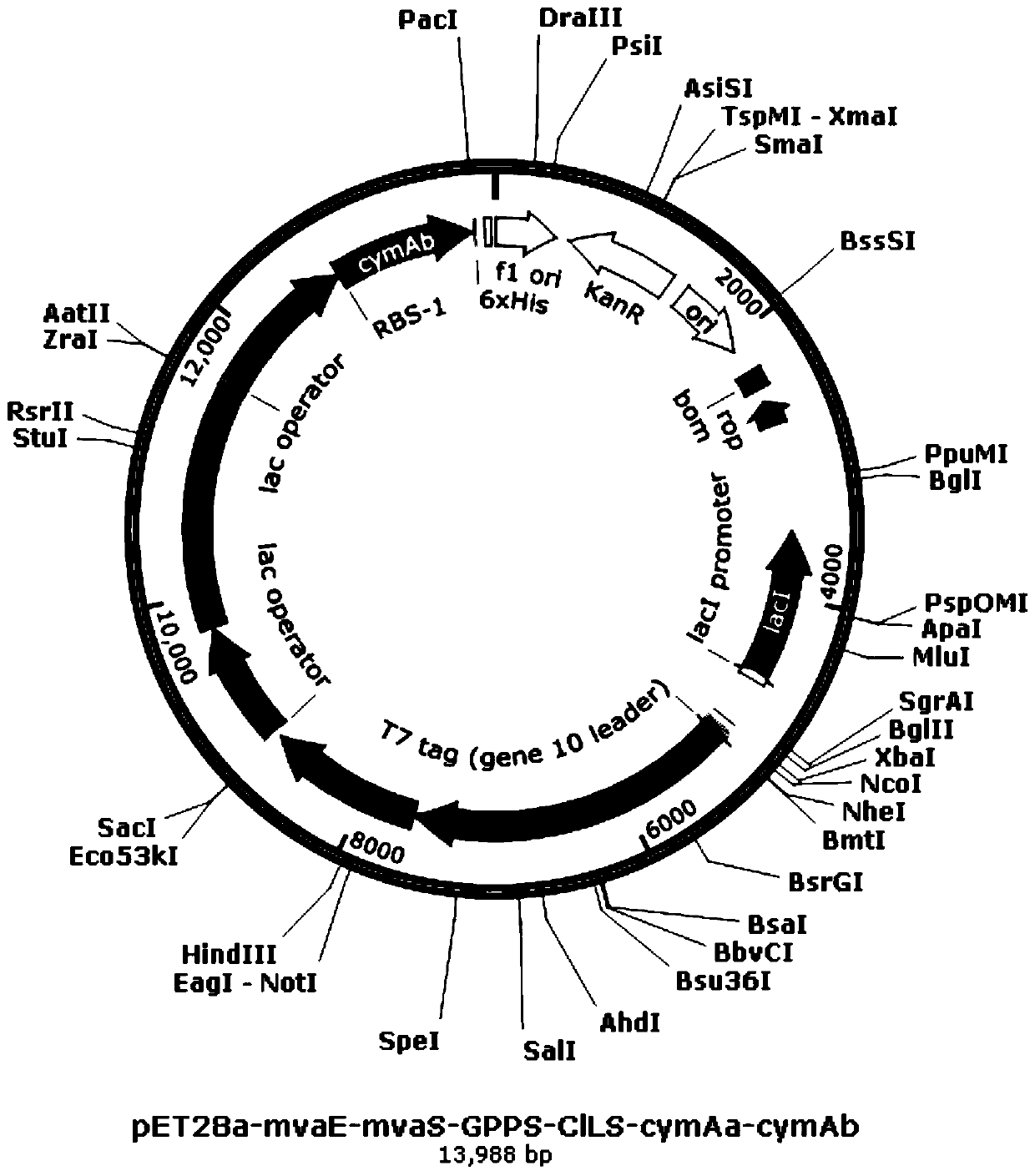

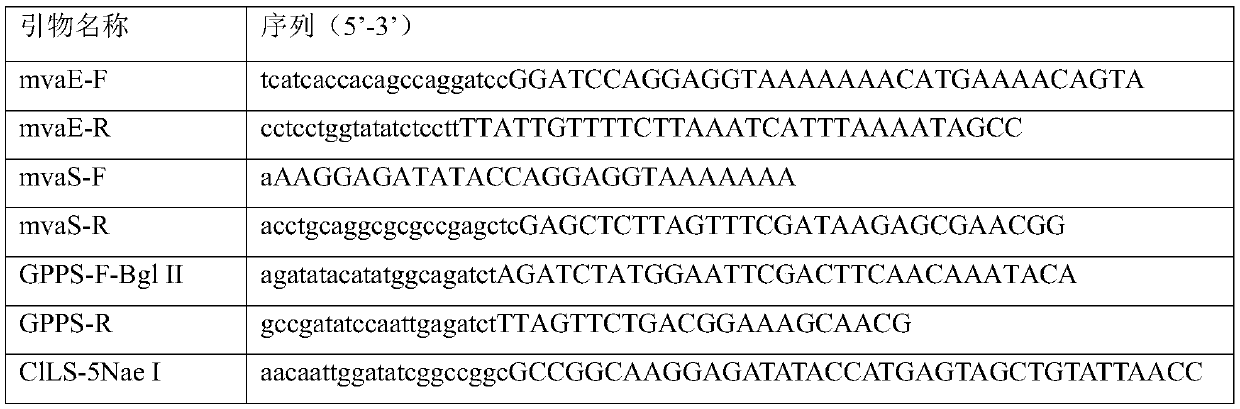

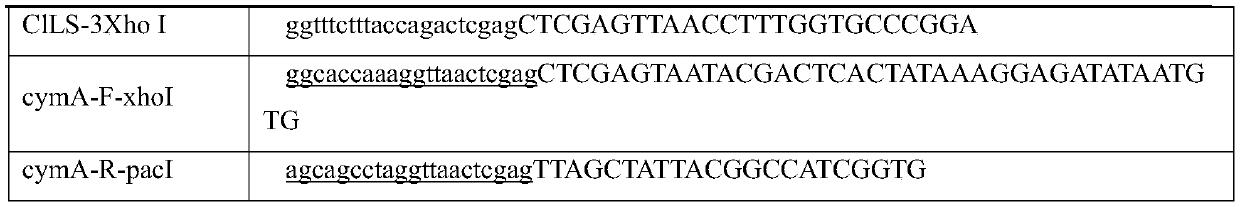

[0045] Example 1. Construction of genetically engineered bacteria producing R-(+)-perillyl alcohol.

[0046] The genetically engineered bacteria producing R-(+)-perillyl alcohol described in this example express HMG-CoA synthetase gene mvaS, acetyl CoA acetyltransferase mvaE, geranyl pyrophosphate synthase gene GPPS, D- Limonene synthase gene ClLS, cymene monooxygenase hydroxylase gene cymAa, cymene monooxygenase reductase gene cymAb, MVA kinase ERG12 gene, MVAP kinase ERG8 gene, mevalonate decarboxylase ERG19 gene and isopentyl pyrophosphate isomerase IDI gene, and the host bacteria is Escherichia coli. The HMG-CoA synthetase gene mvaS, GeneBank ID is AAG02439, derived from E. faecalis E. facecalis; the acetyl CoA acetyltransferase gene mvaE, GenBank NO.AAG02438, derived from E. faecalis E. facecalis; pyrophosphate synthesis Enzyme GPPS gene, Genbank No.AF513112.1, from Abiesgrandis; D-limonene synthase ClLS gene, Genbank No.AF514287.1, from lemon Citrus limon; p-cymene mono...

Embodiment 2

[0060] Example 2. Fermentative production of R-(+)-perillyl alcohol using genetically engineered strains.

[0061] This example is the preparation of R-(+)-perillyl alcohol by shake flask fermentation. The specific method is as follows:

[0062] 1) Cultivation of primary seed liquid: Inoculate the Example 1 on the solid LB plate in LB liquid medium to obtain a single colony of the recombinant strain, and add a final concentration of 50 μg / mL kanamycin and 100 μg / mL ampicillin, Grow at 37°C for 12 hours to obtain a first-grade seed liquid.

[0063] 2) Transfer the primary seed liquid obtained in step 1) to a 250mL saline bottle with 2% (wt) inoculation amount, containing 50mL M9 fermentation medium, and add 200g / L of MgSO when transferring the seed liquid 4 ·7H 2 O 100μL, 500g / L glucose 2.4mL, 1000×trace elements 50μL ((NH 4 ) 6 MoO 24 4H 2 O 0.37g; ZnSO 4 ·7H 2 O 0.29g; H 3 BO 4 2.47g; CuSO 4 ·5H 2 O 0.25g; MuCl 2 4H 2 O 1.58g; distilled water to 100mL), final ...

Embodiment 3

[0070] Example 3. Fermentative production of R-(+)-perillyl alcohol using genetically engineered strains.

[0071] This example is the preparation of R-(+)-perillyl alcohol by fermentation in a 5L fermenter. The specific method is as follows:

[0072] 1) Pick a single colony of the recombinant strain obtained in Example 1 and place it in a test tube containing 4 mL of LB liquid medium, 50 μg / mL kanamycin and 100 μg / mL ampicillin, and culture overnight at 37° C. at 180 rpm.

[0073] 2) Inoculate 2% (wt) of the bacterium liquid of above-mentioned overnight culture into the 500mL Erlenmeyer flask that 100mL fermentation medium is housed, add 40% glucose of 4mL sterilization before inoculation to make the glucose concentration in the medium be 10g / L, add 200 μL of 500 times MgSO 4 ·7H 2 O, 100uL of 1000×trace elements, 100uL of kanamycin stock solution, 100uL of ampicillin stock solution, cultured at 37°C and 180rpm for 7h.

[0074] 3) Before inoculation, 2 mL of kanamycin st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com