Pump body installation mechanism special for vertical dust collector

A technology of installation mechanism and dust collector, which is applied to the components of pumping devices for elastic fluids, variable displacement pump components, machines/engines, etc., and can solve the problem of not being able to adapt to the installation, installation and disassembly of various pump bodies at the same time Not enough convenience, poor safety and stability, etc., to achieve the effect of strong installation flexibility and firmness, improved convenience and disassembly efficiency, strong firmness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

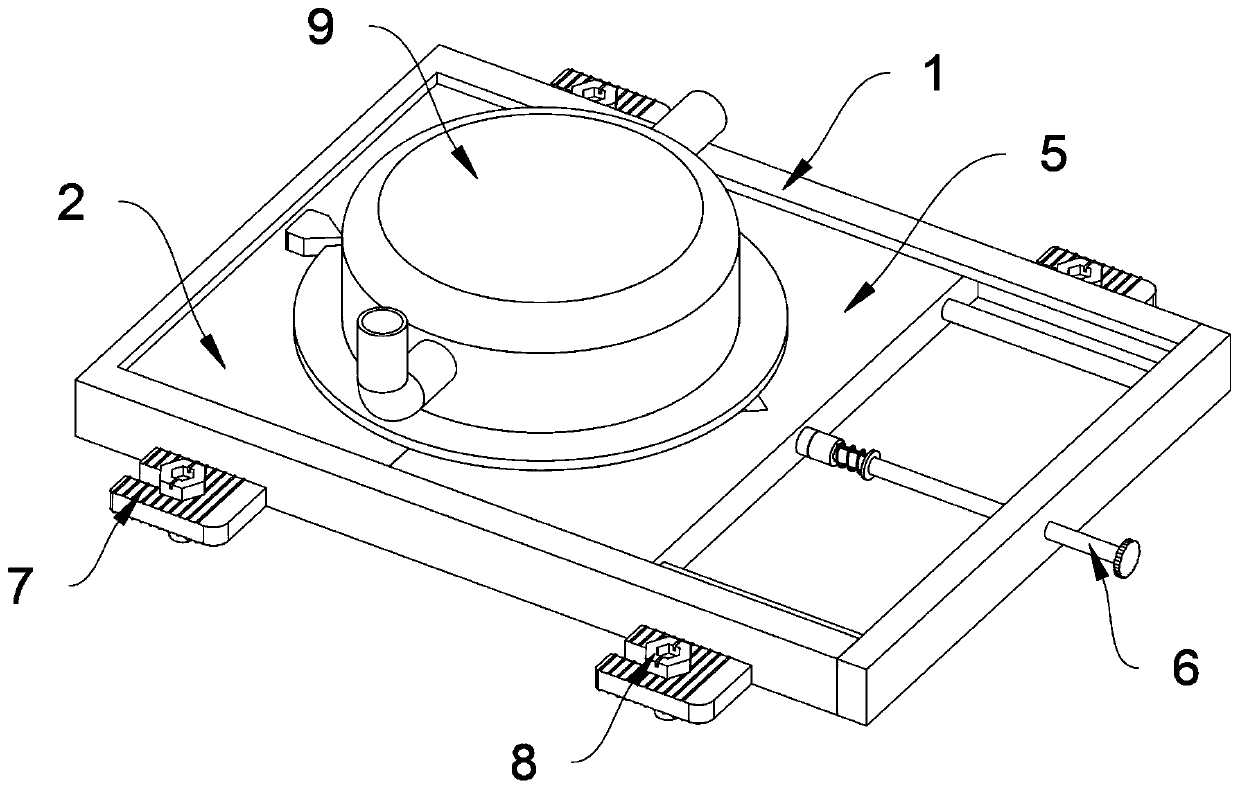

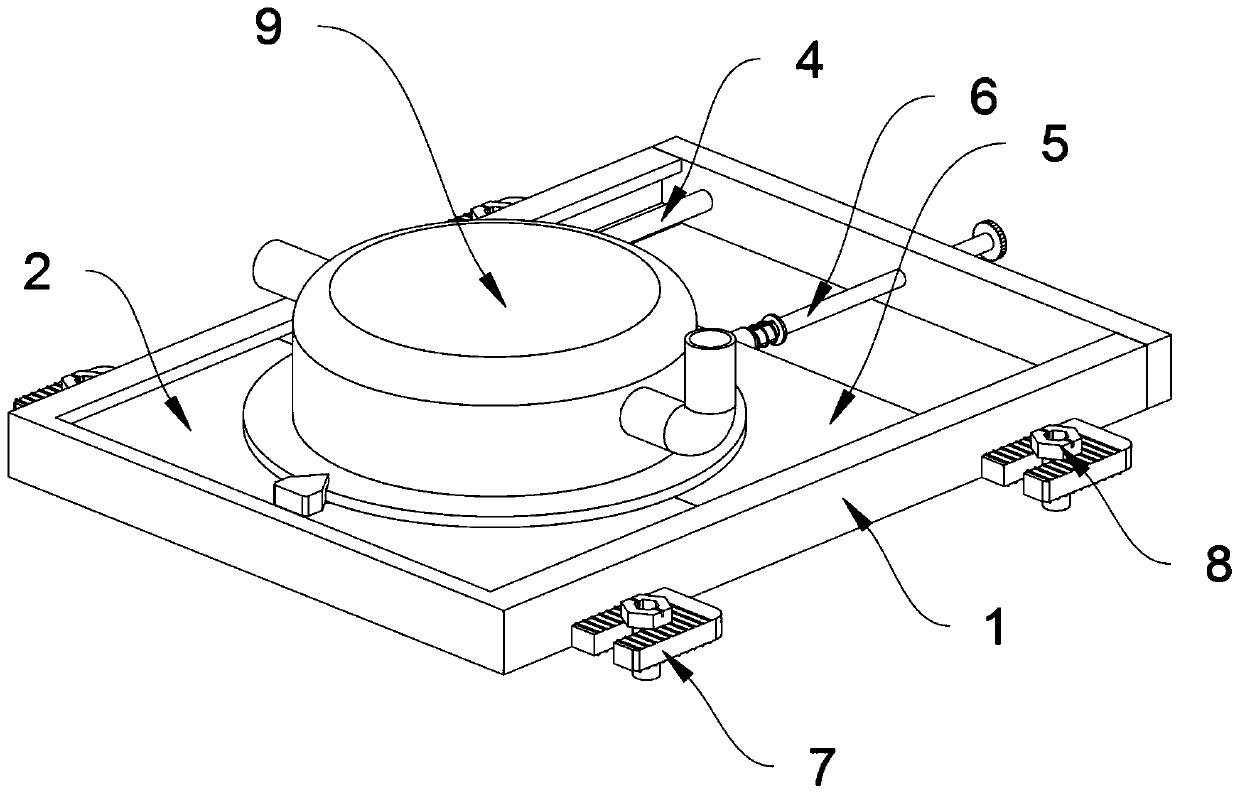

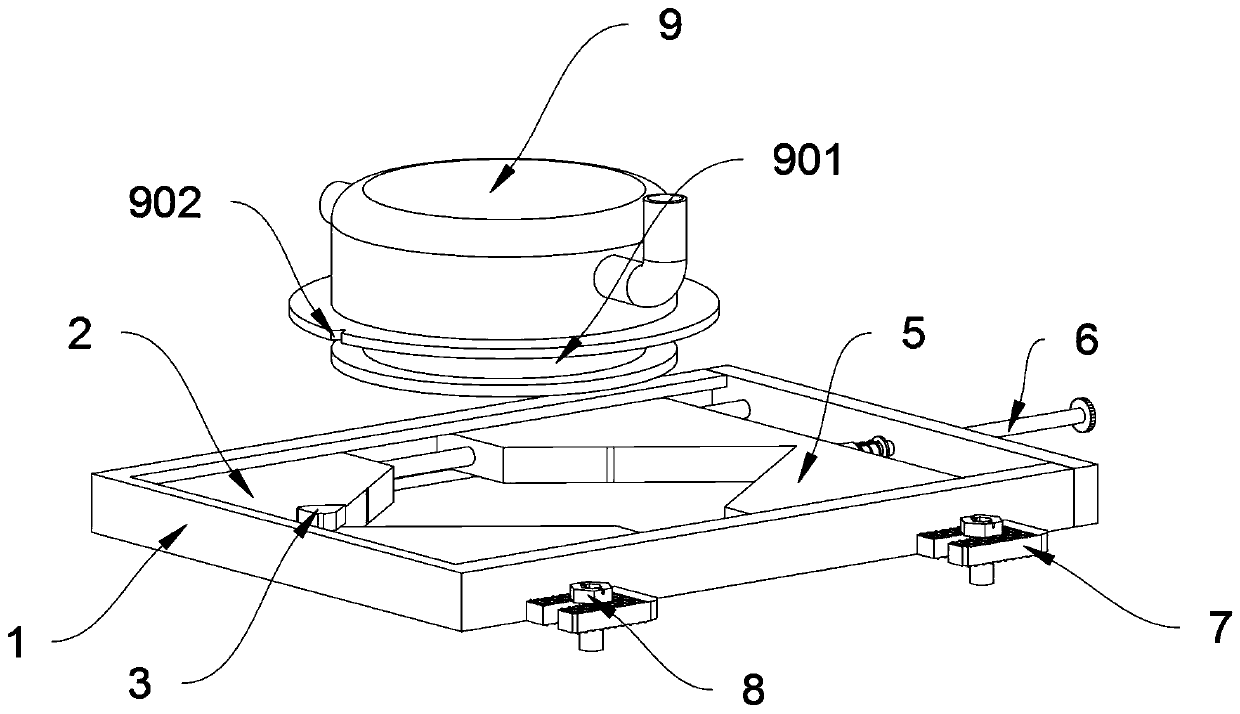

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a special pump body installation mechanism for a vertical dust collector, which includes a mounting seat 1; the mounting seat 1 is a rectangular frame structure, and a fixed block 2 is welded on the inner side of the mounting seat 1; the top surface of the fixed block 2 is welded There is a latch block 3, and two cylindrical rods 4 are welded on the front end of the fixed block 2.

[0036] Reference as figure 1 , the inner side of the mounting seat 1 is provided with a sliding groove, and a movable block 5 is slidably connected in the sliding groove, and the movable block 5 is slidably connected to two cylindrical rods 4 at the same time, so through the sliding groove and the two cylindrical rods The effect of 4 can improve the sliding stability of movable block 5.

[0037] Reference as Figure 4 , the front end of the fixed block 2 is provided with a card slot 01, and the rear end of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap