Rail vehicle with filling level monitoring of a waste water tank

A technology for rail vehicles and containers, applied in the field of rail vehicles, can solve problems such as increasing power fuel reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

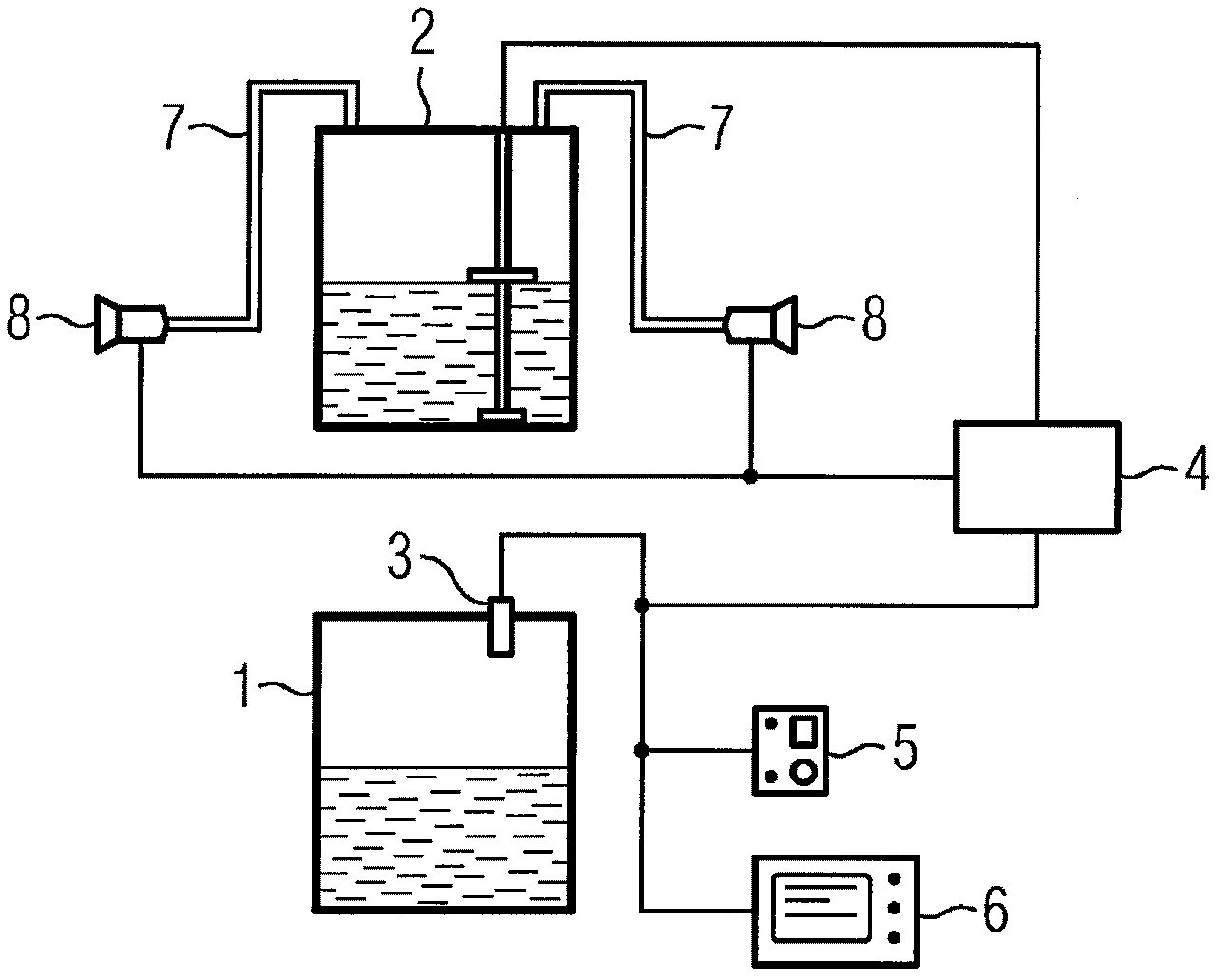

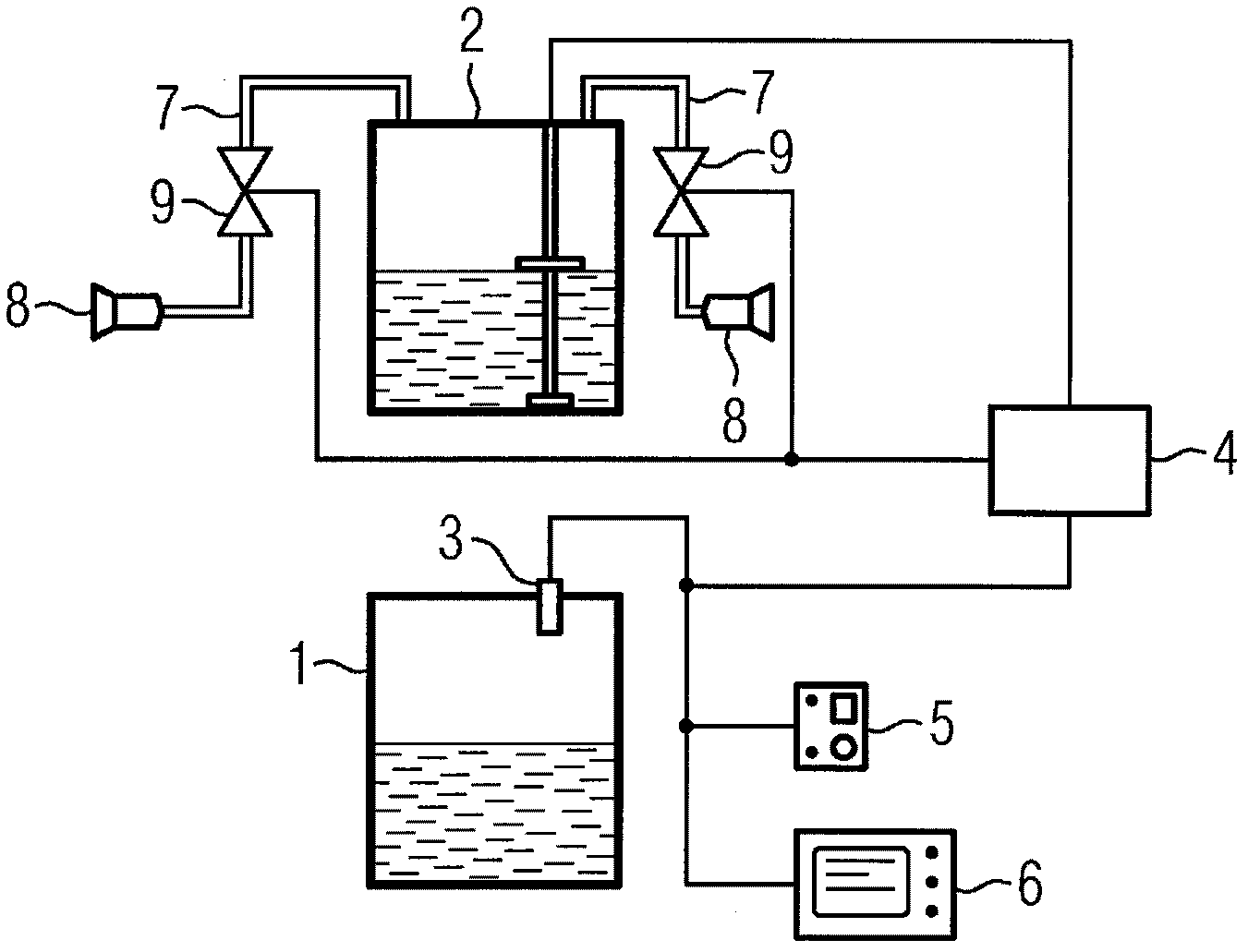

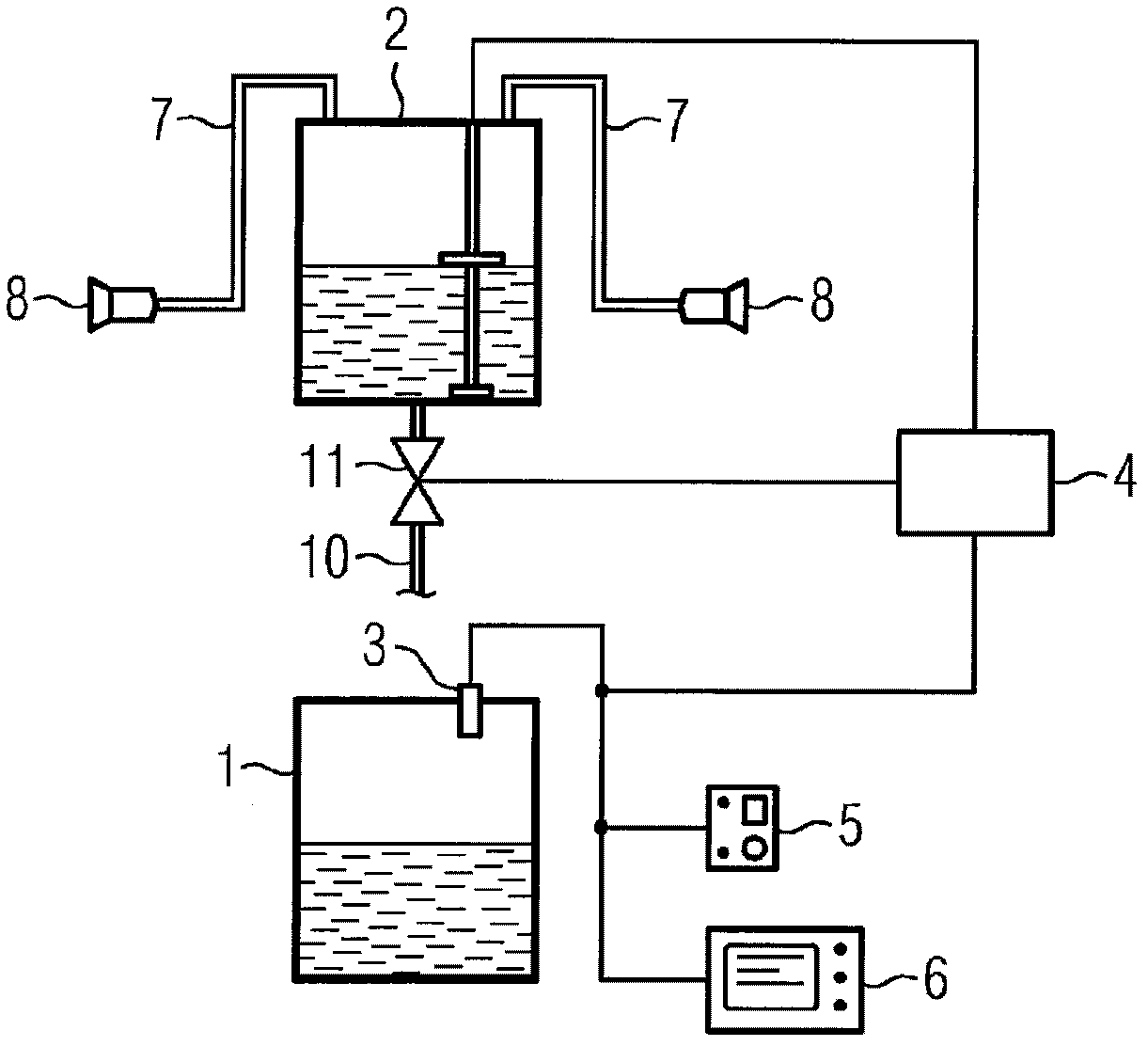

[0016] figure 1 The description in FIG. 1 shows the important components of the sanitary system of a rail vehicle, in particular the waste water container 1 and the fresh water container 2 . The waste water container 1 is equipped with a level sensor. Fill level sensor 3 of waste water container 1 is in a signaling connection with control device 4 , which controls the fill level of fresh water container 2 as a function of the currently detected measured value for the fill level of waste water container 1 .

[0017] Furthermore, the current measured values from the fill level sensor 3 of the waste water container 1 are transmitted to a display device 5 and a vehicle diagnostic device 6 installed on the outside of the vehicle. In this case, the display device 5 is also designed as a simple indicator light, which only displays extreme values exceeding the fill level in the waste water container 1 .

[0018] The filling level in the waste water container 1 is monitored conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com