Pressure vessel valve

A pressure vessel and valve stem technology, applied in the field of pressure vessel valves, can solve problems such as mis-opening of handwheels, and achieve the effects of avoiding mis-opening, improving limit effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

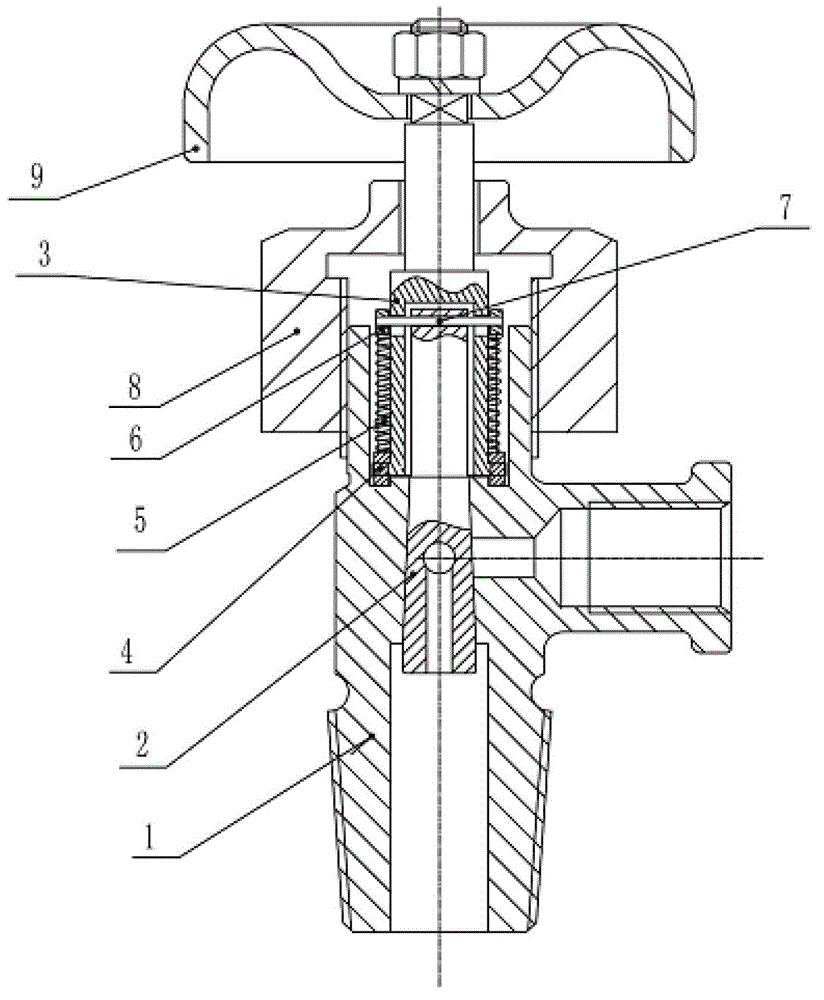

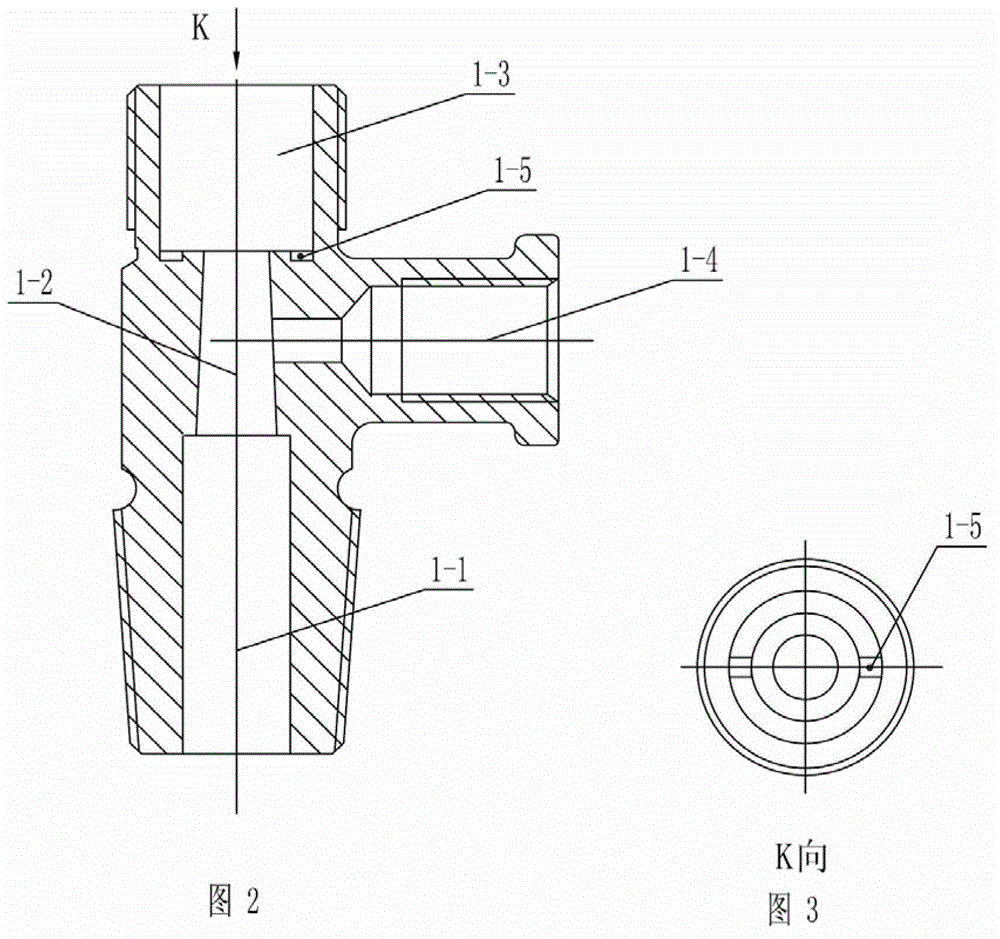

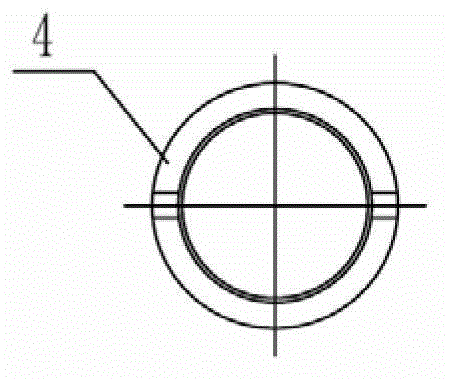

[0025] See Figure 1-10 , the pressure vessel valve suitable for automatic locking in this embodiment includes: a valve body 1, a valve stem 2 arranged in the valve body 1, a lock lever 3 arranged at the upper end of the valve stem 2, and a hand lever arranged at the top of the lock lever 3. Wheel 9; valve stem 2 includes: conical section 2-1 and cylindrical section 2-2 connected to the upper end of the conical section 2-1; valve body 1 includes: the first cylindrical cavity 1-1 at the bottom, the same A conical cavity 1-2 with an axis set at the upper end of the first cylindrical cavity 1-1, which is suitable for sealing fit with the conical section 2-1 of the valve stem 2, and a coaxial line set at the conical cavity The second cylindrical cavity 1-3 at the upper end of 1-2; the side wall of the conical cavity 1-2 is provided with an exhaust port 1-4; the diameter of the upper port of the conical cavity 1-2 is smaller than the second cylindrical cavity 1-3 in diameter to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com