A solar-assisted energy-saving rechargeable organic lithium-sulfur battery

A technology of organic lithium and sulfur batteries, applied in lithium batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of metal lithium consumption, high cost and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

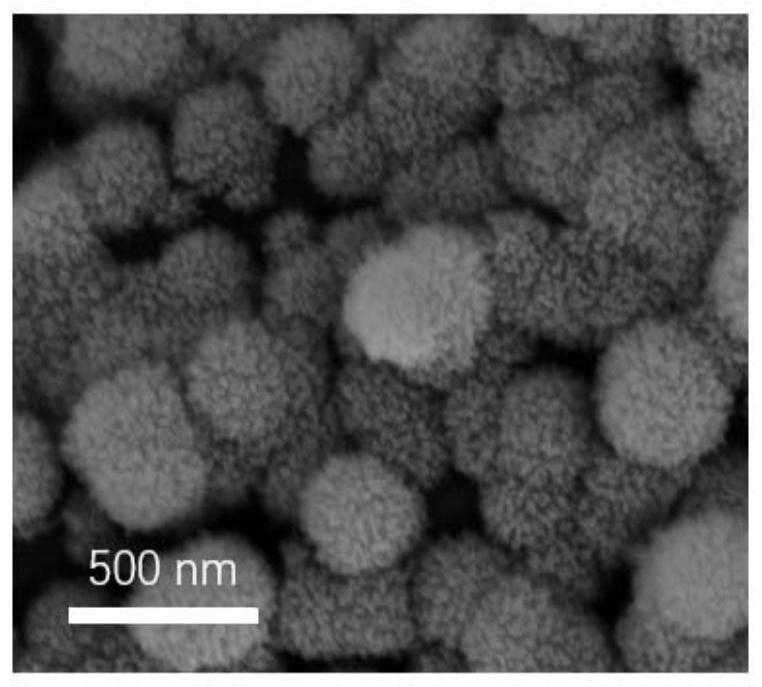

[0033]In this embodiment, first, zinc nitrate and thiourea were dissolved in deionized water respectively to prepare 35ml, 0.03mol / L zinc nitrate solution and 35ml, 0.03mol / L thiourea solution, and the thiourea solution was added to the zinc nitrate solution, stirred for 30 minutes until clear. Then the mixed solution was transferred to the lining of the hydrothermal reaction kettle, heated to 140°C and reacted at this temperature for 8 hours. After the reaction was completed, it was naturally cooled to room temperature, then taken out, and then centrifugally washed with deionized water and absolute ethanol. Finally put it into an oven at 60° C. and dry for 4 hours to obtain spherical ZnS particles with a size of 200-300 nanometers.

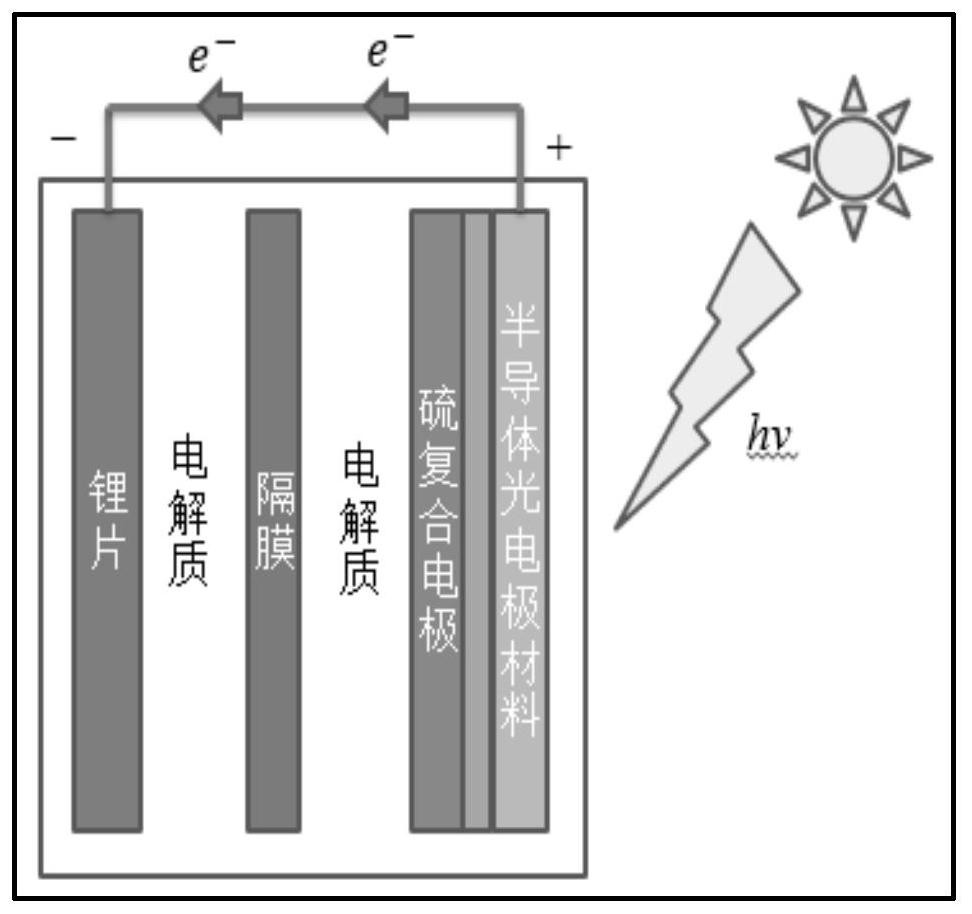

[0034] Such as figure 1 As shown, the light-assisted charging lithium-sulfur battery structure includes a lithium sheet, a diaphragm, a sulfur composite electrode, and a semiconductor photoelectrode material that are vertically arranged in paral...

Embodiment 2

[0039] In this example, TiO 2 Preparation of SrTiO as a precursor 3 Photoelectrode, the specific process is as follows:

[0040] 1. Preparation of TiO with different morphologies 2 Precursor:

[0041] (1) Growth of TiO on carbon paper 2 Nanosheets: Add 30 μl of diethylenetriamine (DETA) to 42ml of isopropanol, stir for 5 minutes, add 1.5ml of titanium isopropoxide, stir for 10 minutes, and transfer the mixed solution to the lining of the hydrothermal reaction kettle. Put carbon paper in the inner lining of the reaction kettle, raise the temperature to 200°C and keep it at this temperature for 24 hours, take out the carbon paper after the reaction is finished and cool it down to room temperature naturally, add absolute ethanol to carry out centrifugal washing; finally, the carbon The paper was dried in an oven at 60°C for 12 hours, and the uniform growth on the carbon paper was white in color and about 20 nanometers in thickness. 2 Nanosheets.

[0042] (2) Growth of TiO o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com