LED display point by point correction method

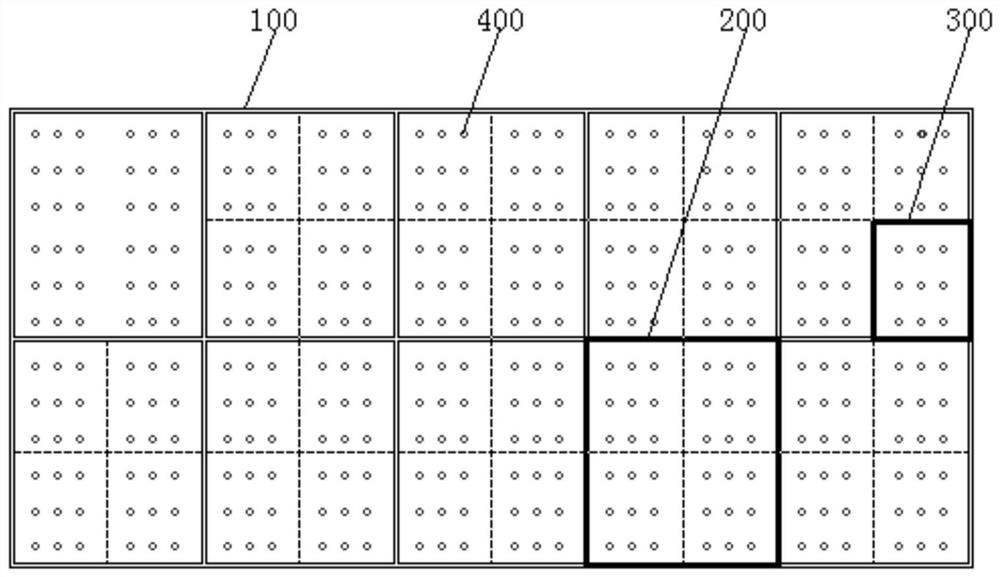

An LED display, point-by-point calibration technology, applied in static indicators, instruments, etc., can solve the problems of deviation of calibration results, neglect of LED single lamp characteristics, and inconsistent LED single lamp characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100]In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the drawings and specific embodiments.

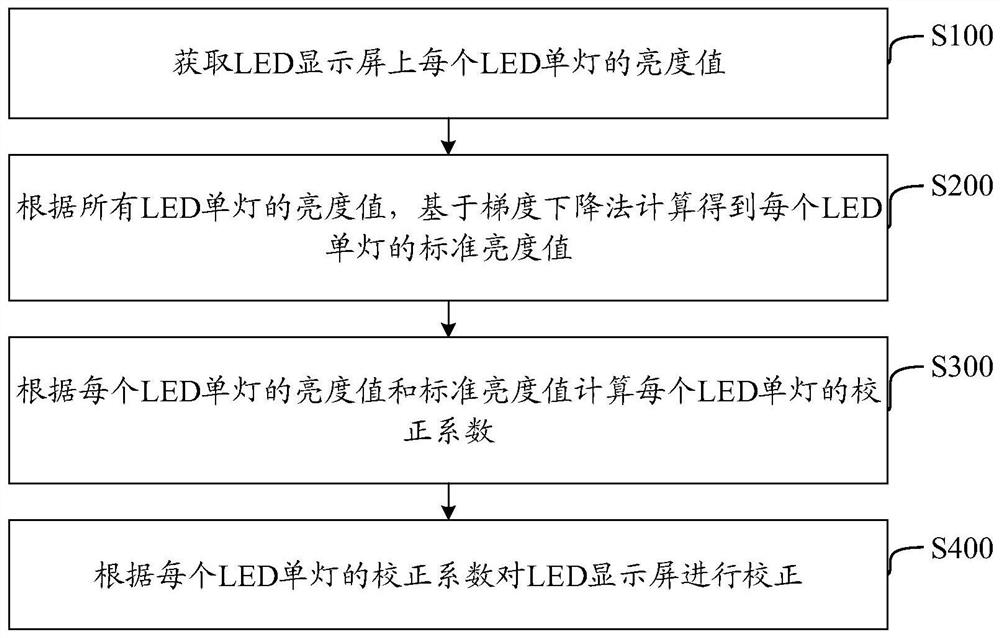

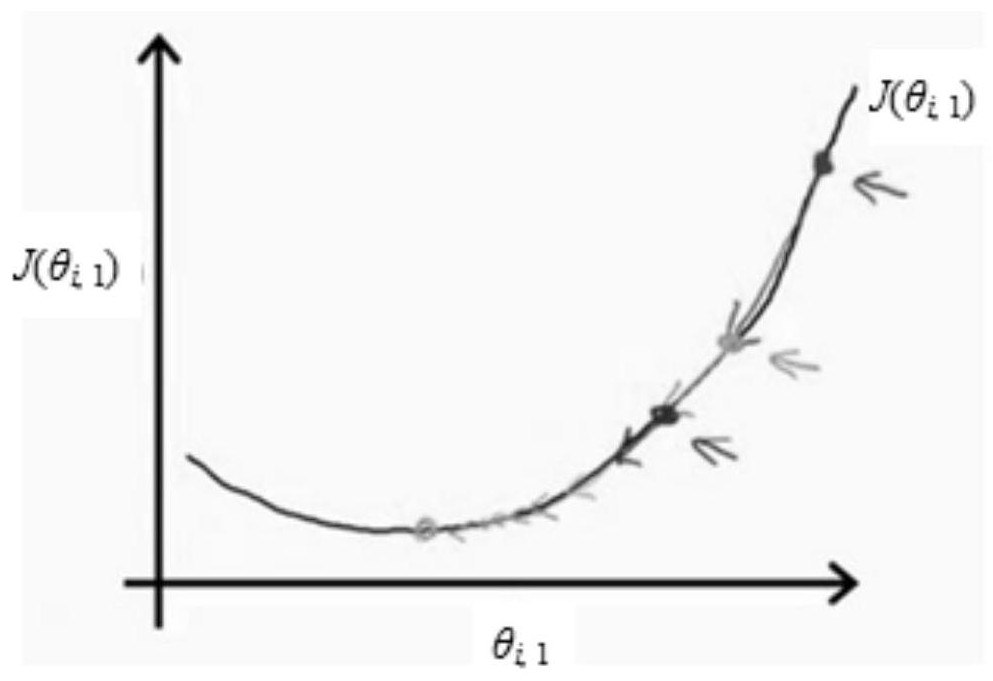

[0101]The embodiment of the present invention provides a point-by-point correction method for an LED display screen, such asfigure 2 As shown, the method includes:

[0102]Step S100: Obtain the brightness value of each LED single lamp on the LED display screen.

[0103]In this step, the method to obtain the brightness value of each LED single lamp is generally: light the LED display, take an image of the LED display through the camera, preprocess the image, and obtain the brightness of each LED single lamp from the image value. Generally, the gray value of the corresponding position of the image is used as the brightness value of the single LED light. For a color display screen, it is necessary to take images of the three primary colors of RGB and correct them se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com