Vertical type pay-off rack

A pay-off frame and vertical technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of easy entanglement of cables, cable friction damage, and inconvenient manpower, etc., to achieve The effect of overcoming the laborious problem of pulling the wire, overcoming the kink and winding, and improving the quality of the off-line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

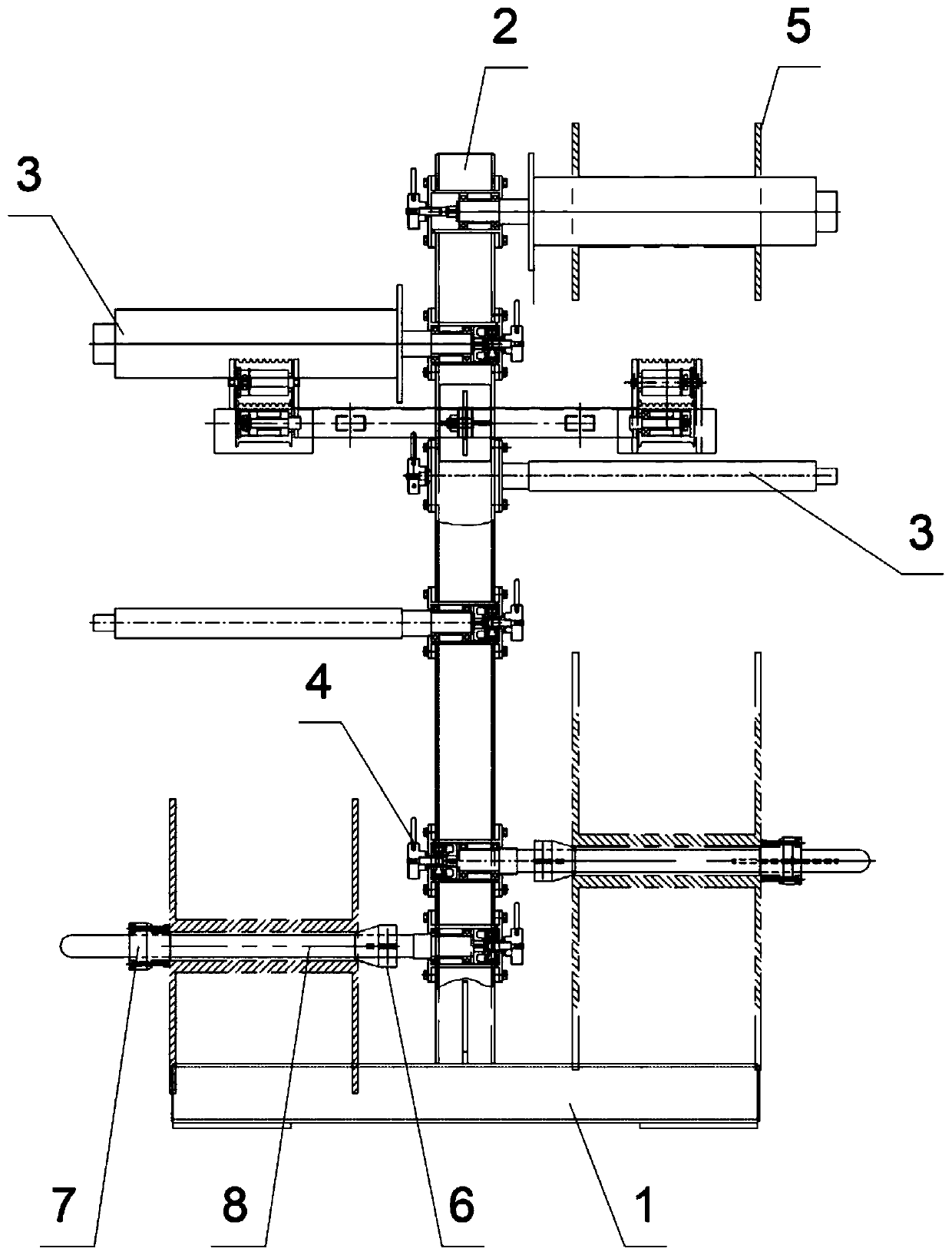

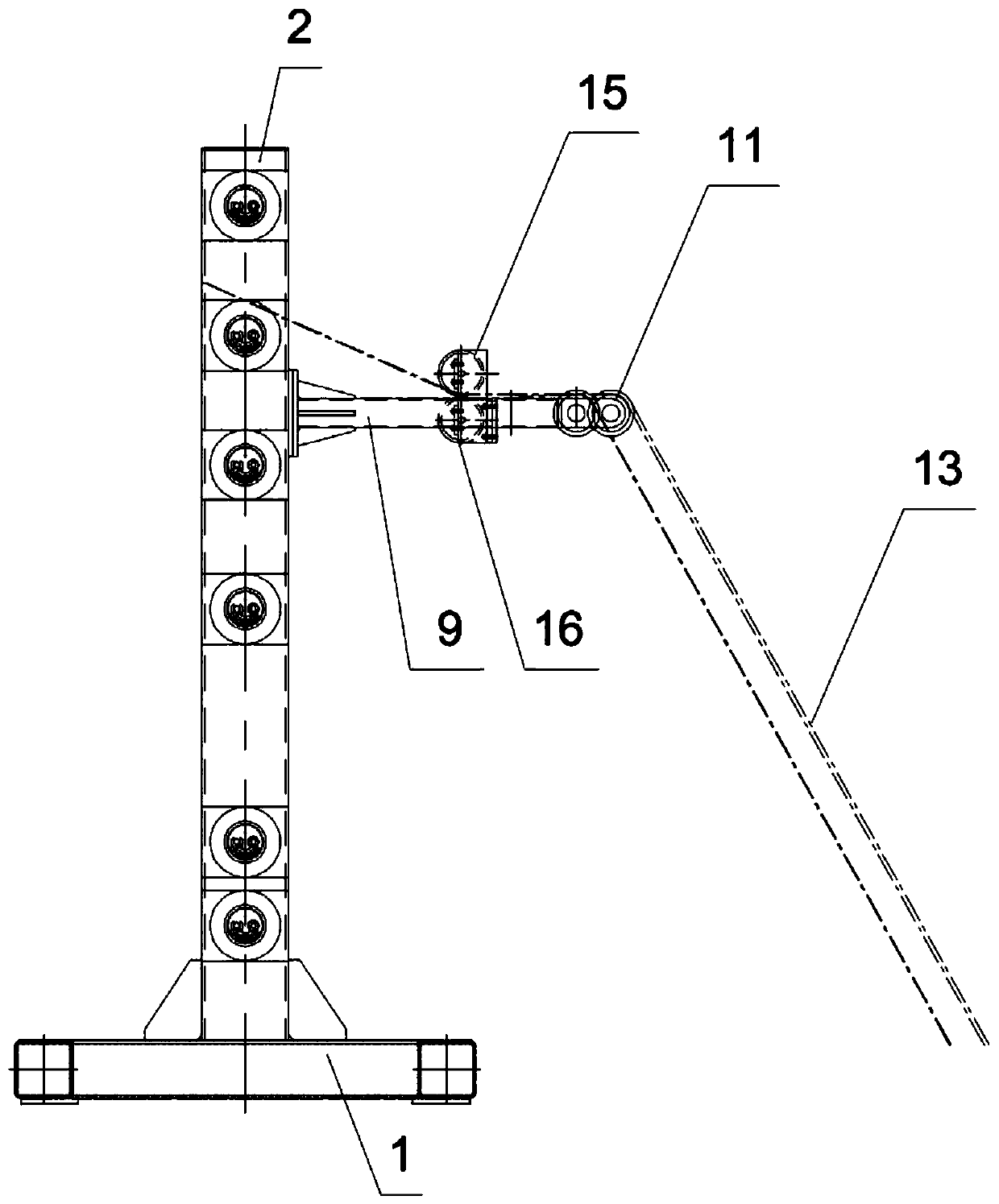

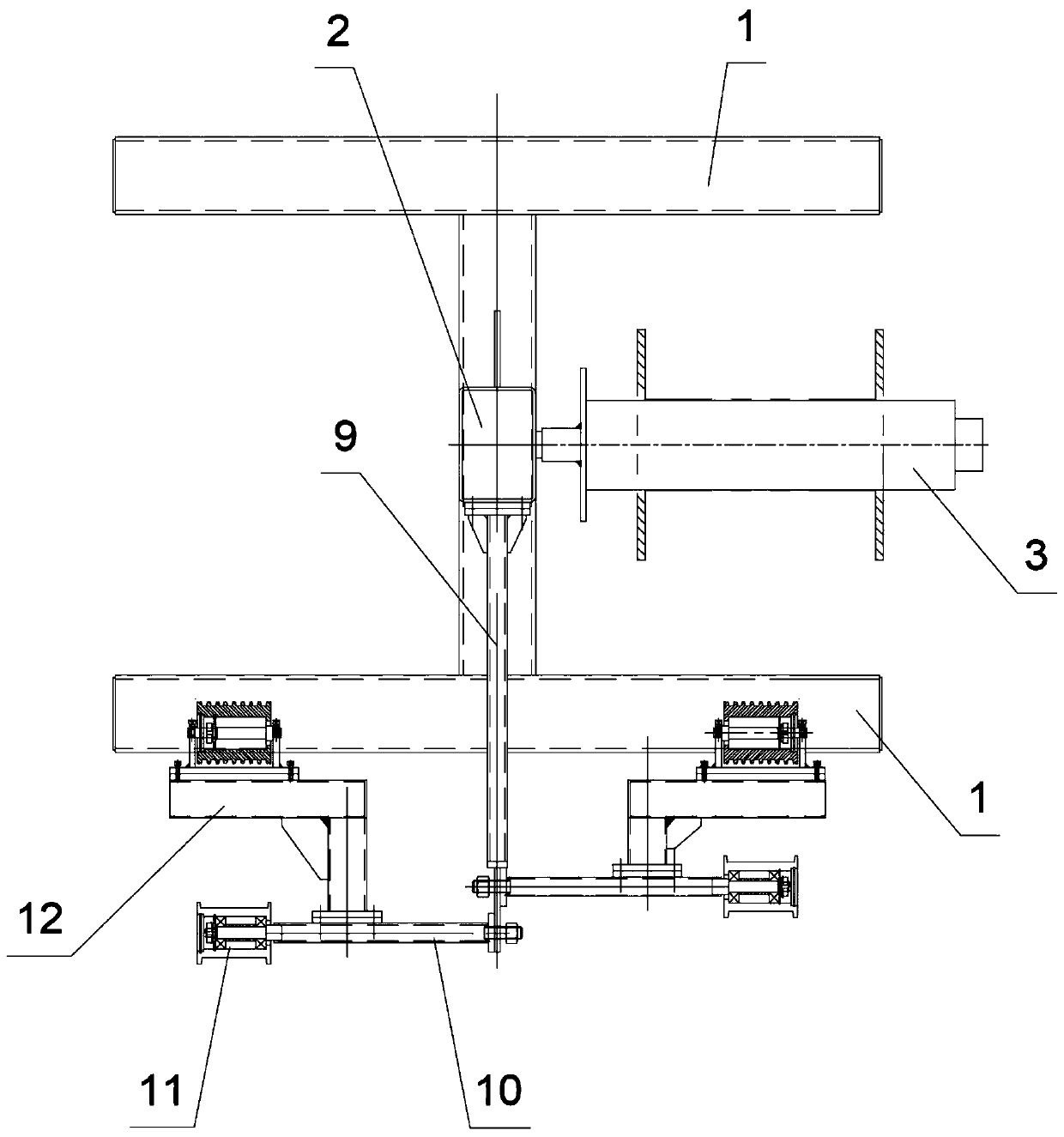

[0029] Such as Figure 1 to Figure 3 As shown, a vertical pay-off frame includes a frame composed of a base 1 and a column 2, on the column 2 there are a plurality of rotating shafts 3 perpendicular to the column 2 for placing cable reels, and the rotating shaft 3 is vertically arranged with the On both sides of the column 2, in this embodiment, there are three on the left side and three on the right side of the column 2, and there is a certain distance between the two rotating shafts 3, which is convenient for placing the cable reel 5. A bearing is arranged between one end of the rotating shaft 3 and the column 2, and a braking device 4 for stopping the rotation of the rotating shaft 3 is arranged at the end of the bearing. Through the above technical solution, the cable reel 5 can be placed on the rotating shaft 3 for off-line operation, which not only saves the storage space of the cable 13, but also facilitates off-line, improves off-line efficiency, and avoids wear and te...

Embodiment 2

[0040] Such as Figure 7 As shown, the difference between this embodiment and the first embodiment lies in that a shaft sleeve corresponding to the inner diameter of the cable reel 5 is sheathed on the rotating shaft 3 . The diameter of the rotating shaft 3 is changed by setting the shaft sleeve, so that the diameter of the rotating shaft 3 and the inner diameter of the cable reel 5 are fixed concentrically, which overcomes the problem caused by the non-concentric rotation of the cable reel and the rotating shaft when the operator pulls the wire during the off-line process. The laborious problem of pulling wires can improve the efficiency of offline.

[0041] The shaft sleeve includes an upper shaft sleeve 24 and a lower shaft sleeve 25. A positioning pin 26 for driving the rotating shaft to rotate is provided on the upper shaft sleeve 24 and / or the lower shaft sleeve 25, and a positioning pin corresponding to the positioning pin 26 is provided on the rotating shaft 3. groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com