Pump bearing combined load testing fixture

A combined load, shaft-connected bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problems that cannot meet the actual use requirements and the difference in operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] When the following terms such as "upper" and "lower", "right" and "left" or similar relative expressions are used in this embodiment, these only refer to the drawings and not necessarily the actual usage.

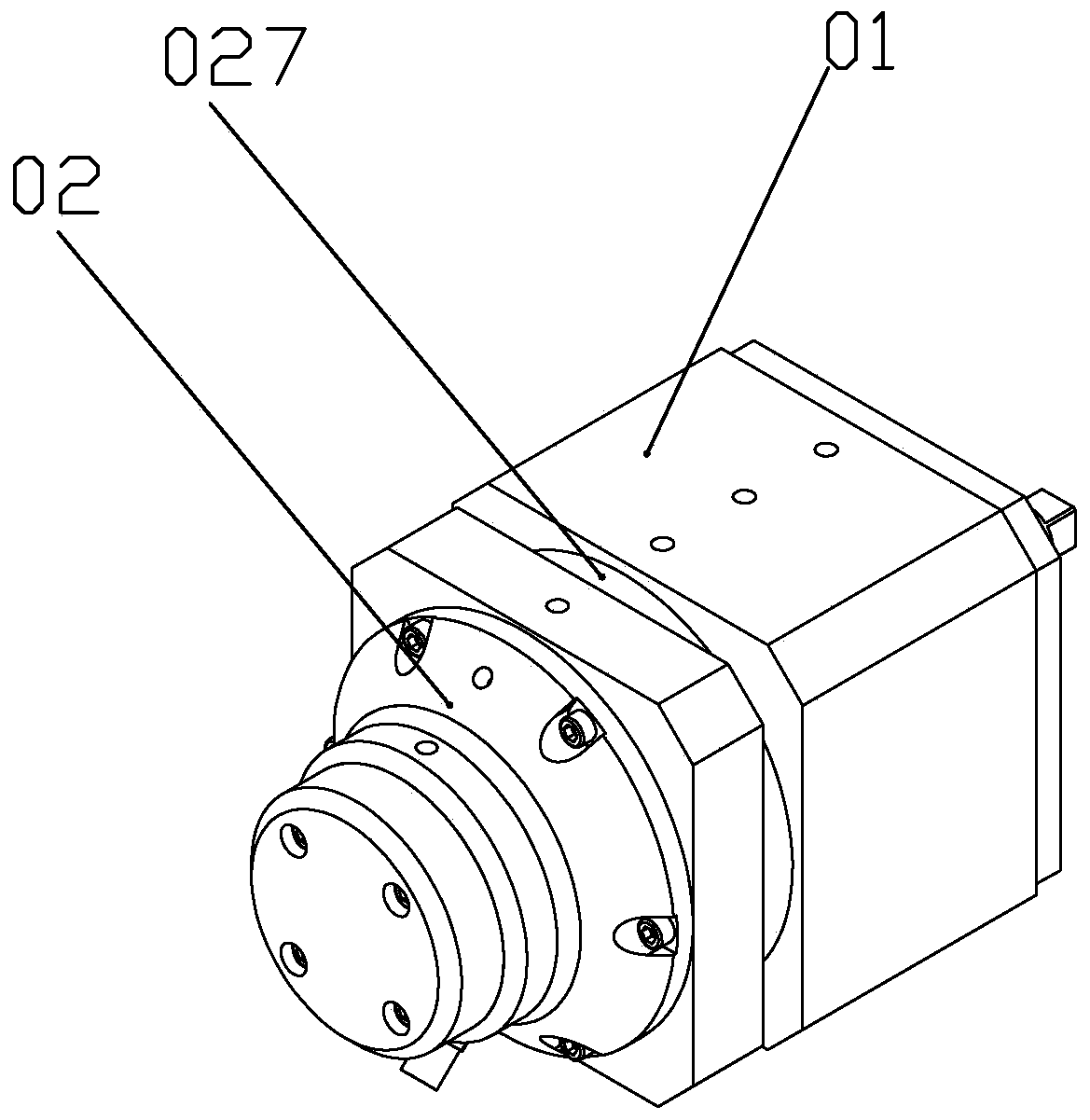

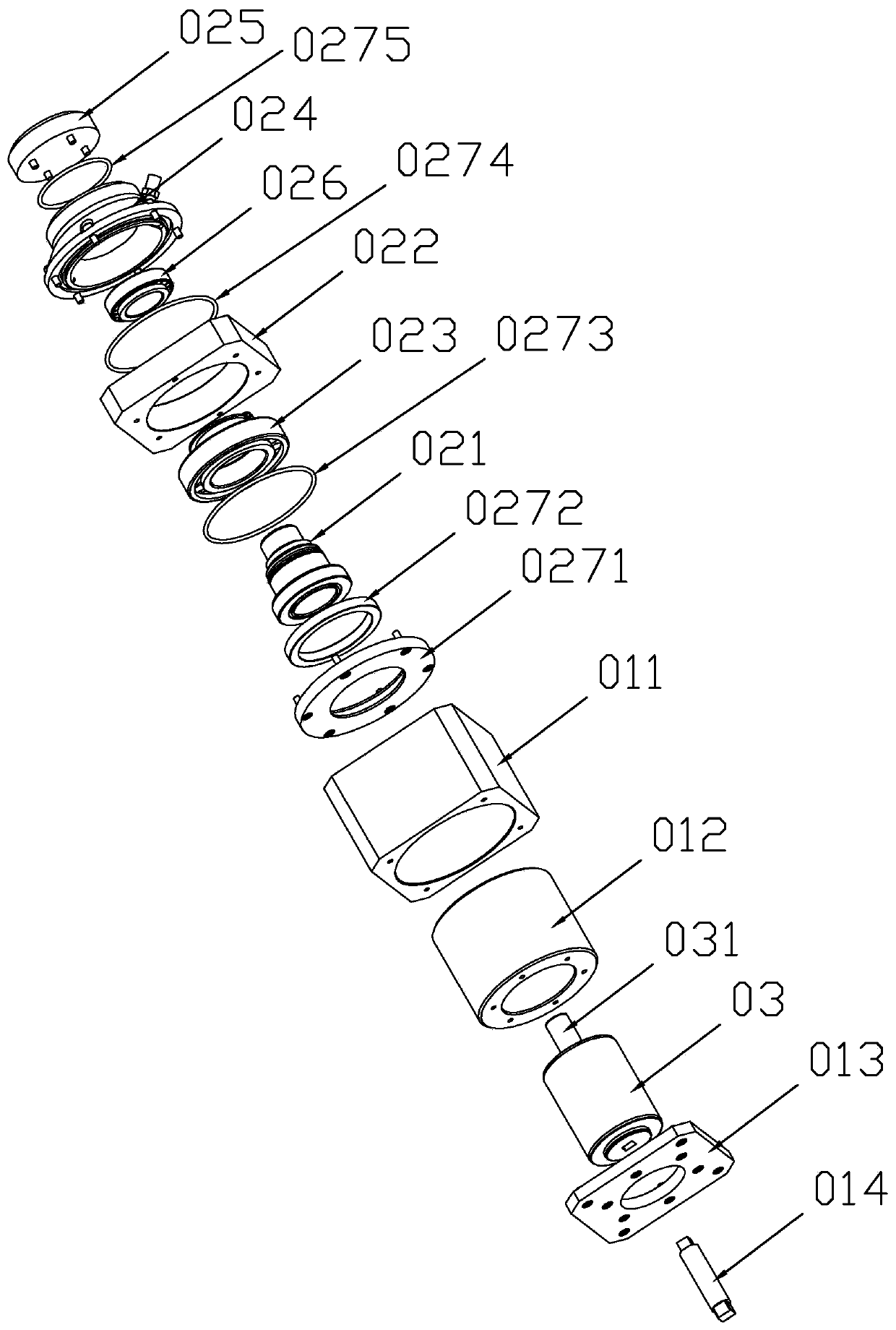

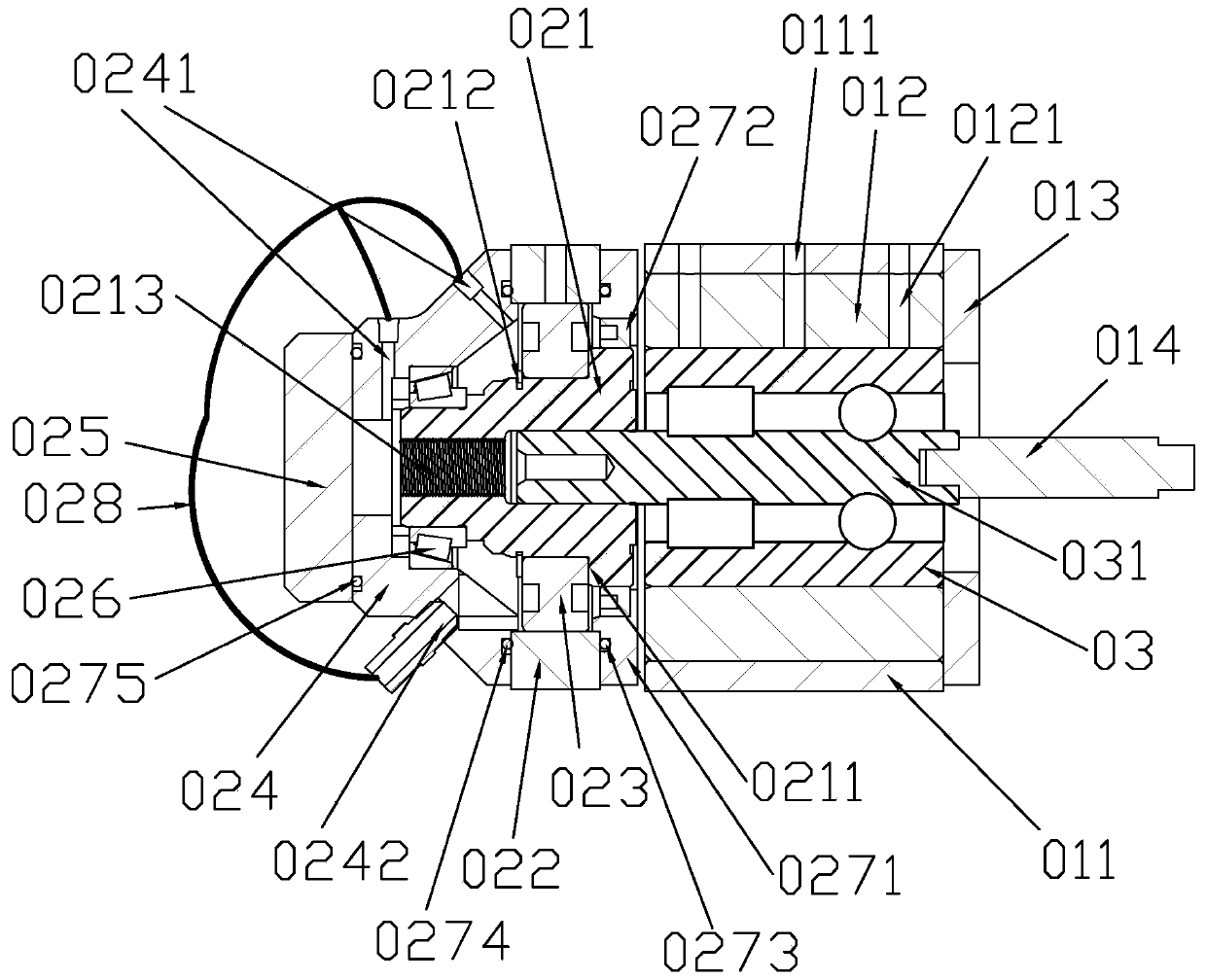

[0029] Specific embodiments of the present invention such as Figure 1-5As shown, a shaft-connected bearing combined load test tool includes a detection mechanism 01 and a loading mechanism 02. The detection mechanism 01 includes a fixed sleeve 011 sleeved on the outside of the shaft-connected bearing 03 to be tested and a device for driving the shaft-connected bearing 03 to be tested to rotate. The driving part, in this embodiment, the driving part is a servo motor 015 with a drive shaft 014, a bushing 012 is provided between the fixed sleeve 011 and the bearing 03 of the shaft to be tested, and the end of the shaft to be tested and the bearing 03 away from the loading mechanism 02 There is an end liner 013 fixedly connected with the fixed sleeve 011 and the bushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com