Self-adaptive HDMI cable

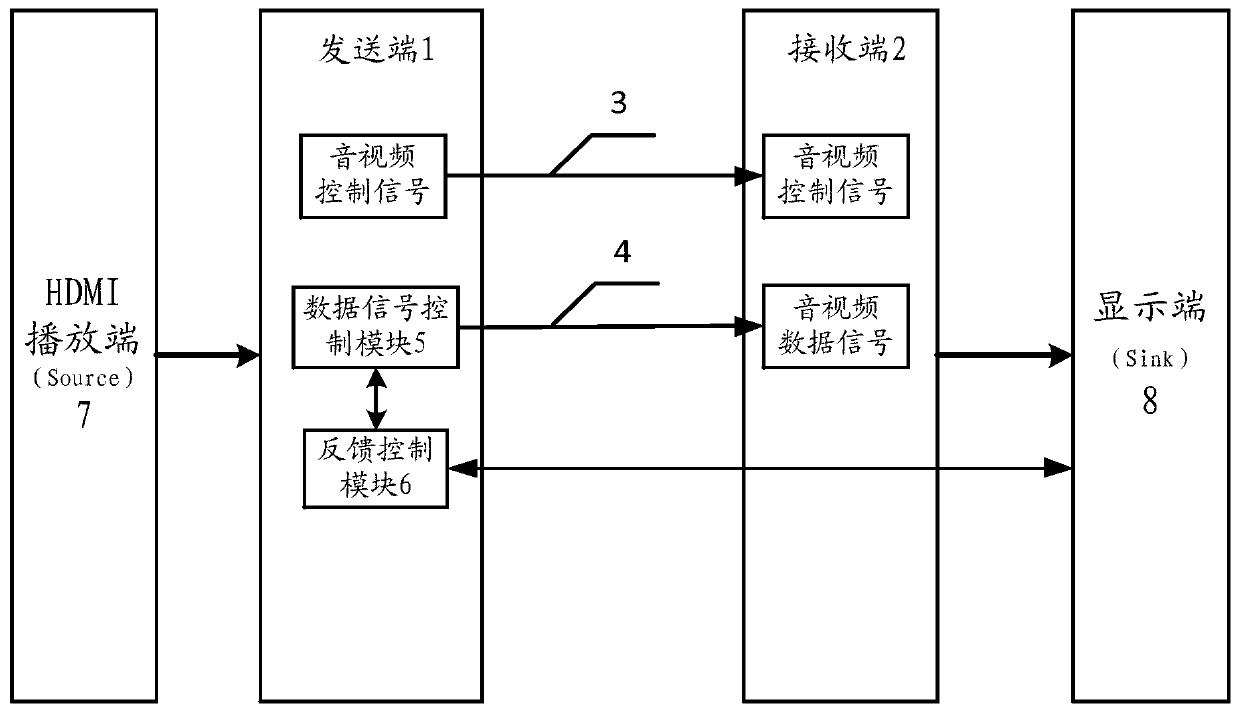

A self-adaptive and cable-based technology, applied in the transmission mode of copper wire and optical fiber, and in the field of self-adaptive HDMI cable, can solve the problems of Sink’s poor ability to receive high-speed signals, black screen and snowflakes, display flickering, etc., and achieve stability and the effect of optimal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

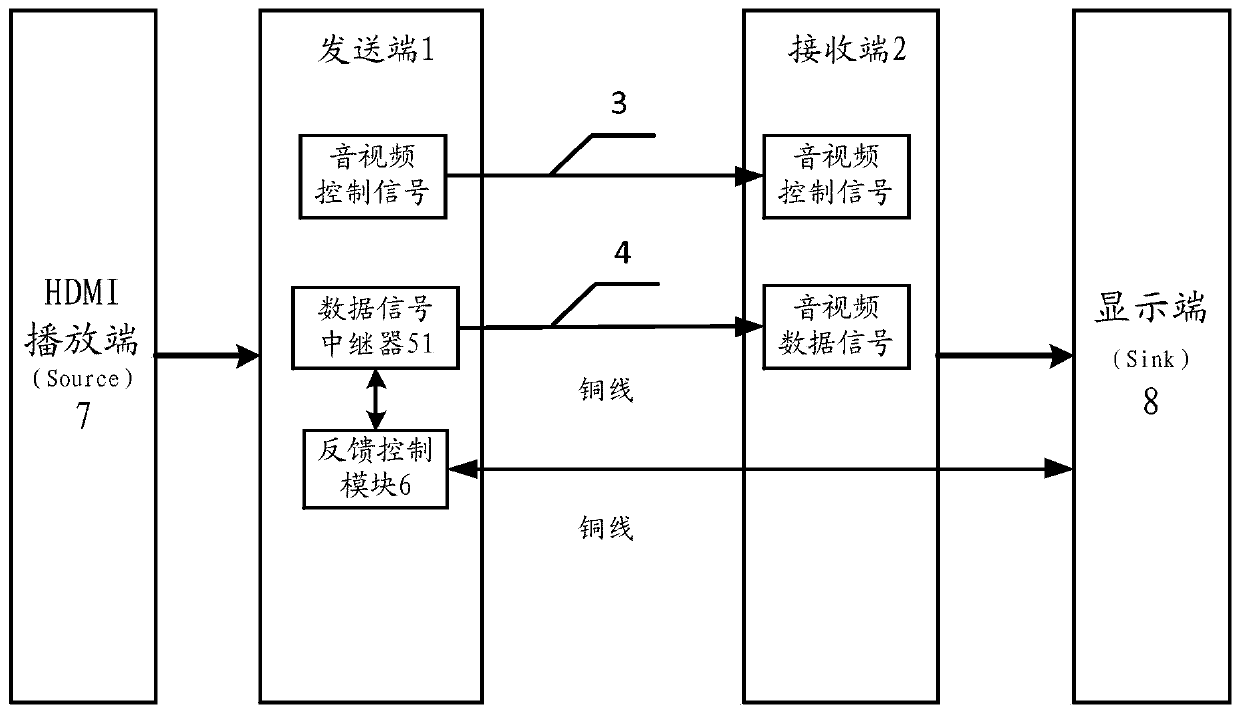

[0048] Embodiment 1: The data signal transmission medium is copper wire.

[0049] see figure 2 , when the data wire 4 is a copper wire, the data signal control module 5 is a data signal repeater (Redriver, Repeat) 51 .

[0050] The feedback control module 6 communicates with the data signal repeater 51 and / or the display terminal 8, so as to obtain the signal transmission quality in the cable.

[0051] specific:

[0052] see Figure 5 , the feedback control module 6 communicates with the data signal repeater 51, obtains the current data signal transmission speed and frequency, actively adjusts the configuration information in the data signal repeater 51, and directly configures the data with parameters suitable for different speeds and frequencies The signal repeater 51 allows the data signal repeater to operate according to the specified configuration.

[0053] The feedback control module 6 communicates with the data signal repeater 51, adjusts and actively adjusts the c...

Embodiment 2

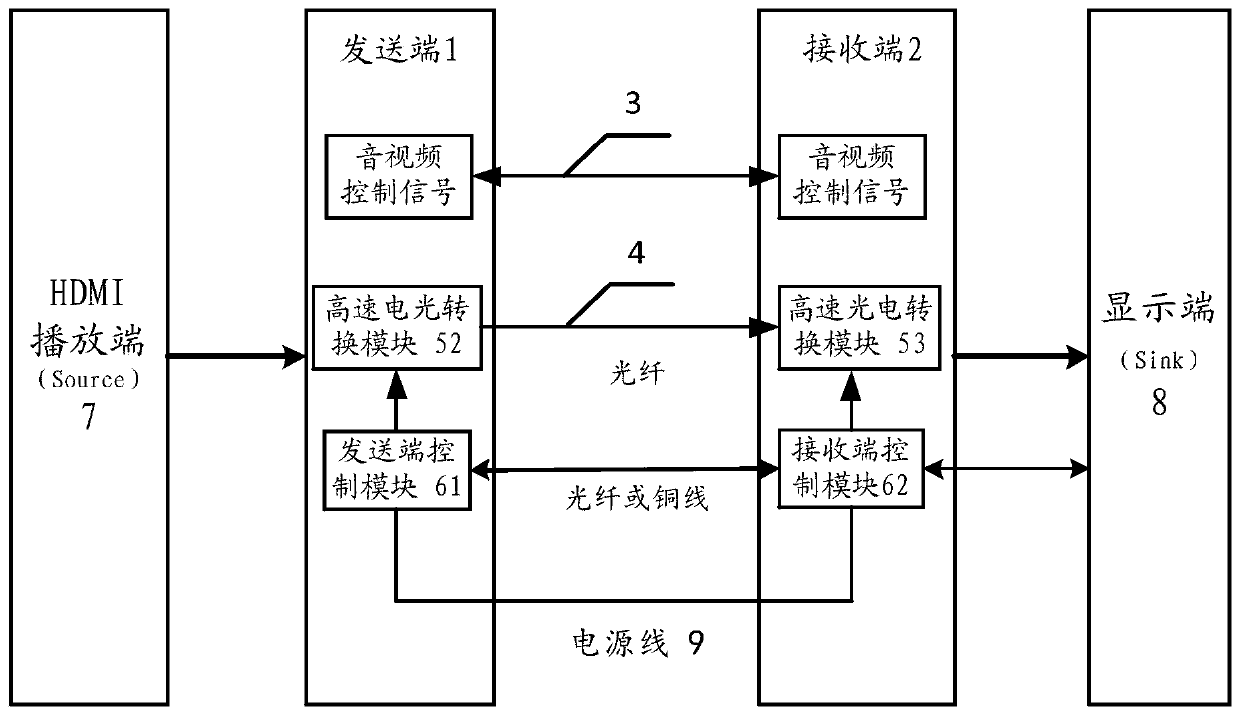

[0056] Embodiment 2: The data signal transmission medium is an optical fiber

[0057] see figure 2 , when the data line 4 is an optical fiber, the data signal control module 5 includes a high-speed electro-optical conversion module 52 located at the sending end of the data line 4, and a high-speed photoelectric conversion module 53 located at the receiving end of the data line 4, and the feedback control module 6 includes a high-speed electro-optical conversion module located at the receiving end of the data line 4 The sending end control module 61 of the sending end, and the receiving end control module 62 positioned at the receiving end control module, the sending end control module 61 communicates with the high-speed electro-optic conversion module 52, and the receiving end control module 62 communicates with the high-speed photoelectric conversion module 53 respectively To communicate with the display terminal 8, the control module 61 of the transmitting terminal and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com