Glass curtain wall and disassembly and assembly method thereof

A glass curtain wall and wall panel technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor stability, low strength, complex structure of disassembly and assembly tools, etc., and achieve the effect of high connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

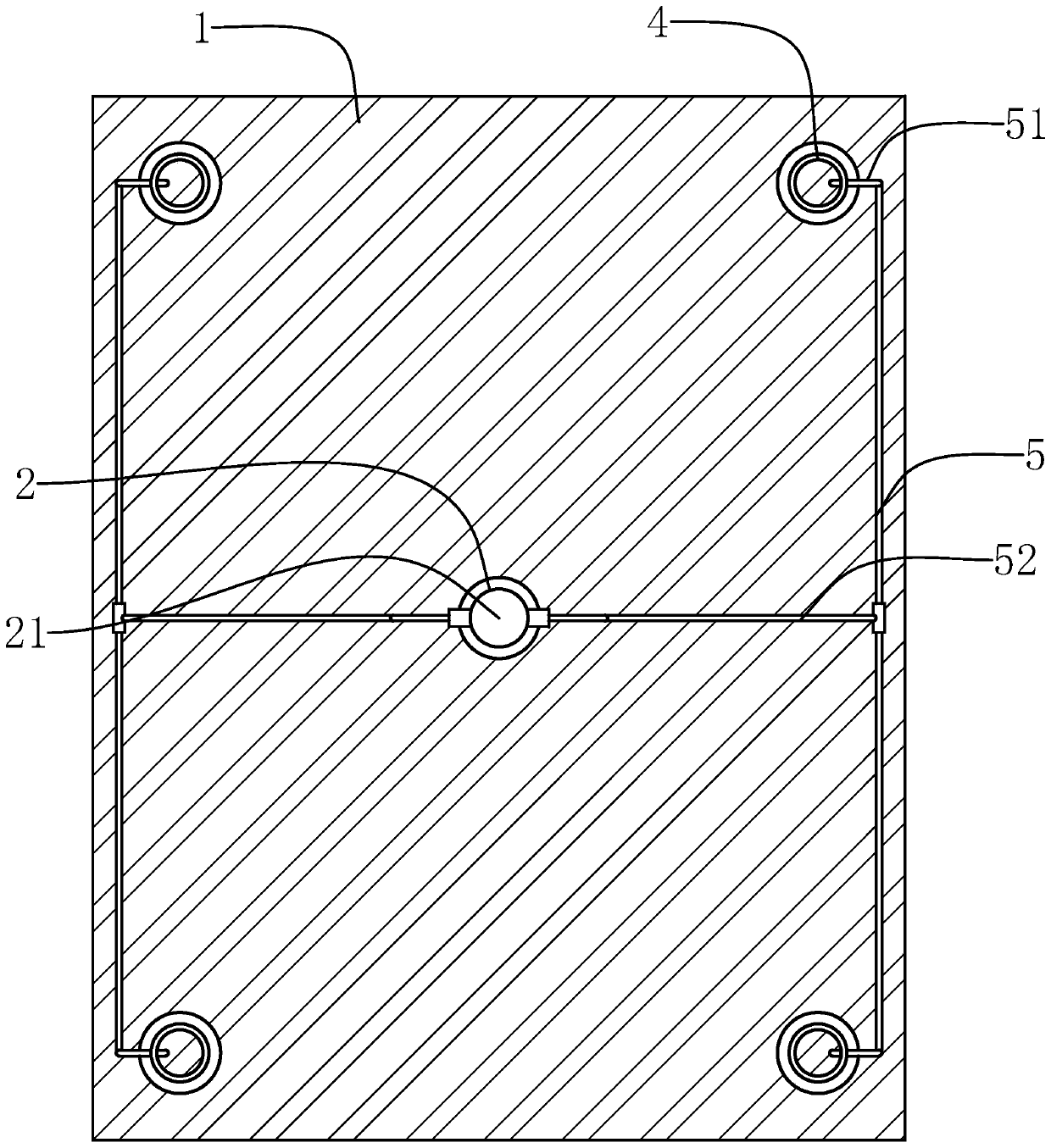

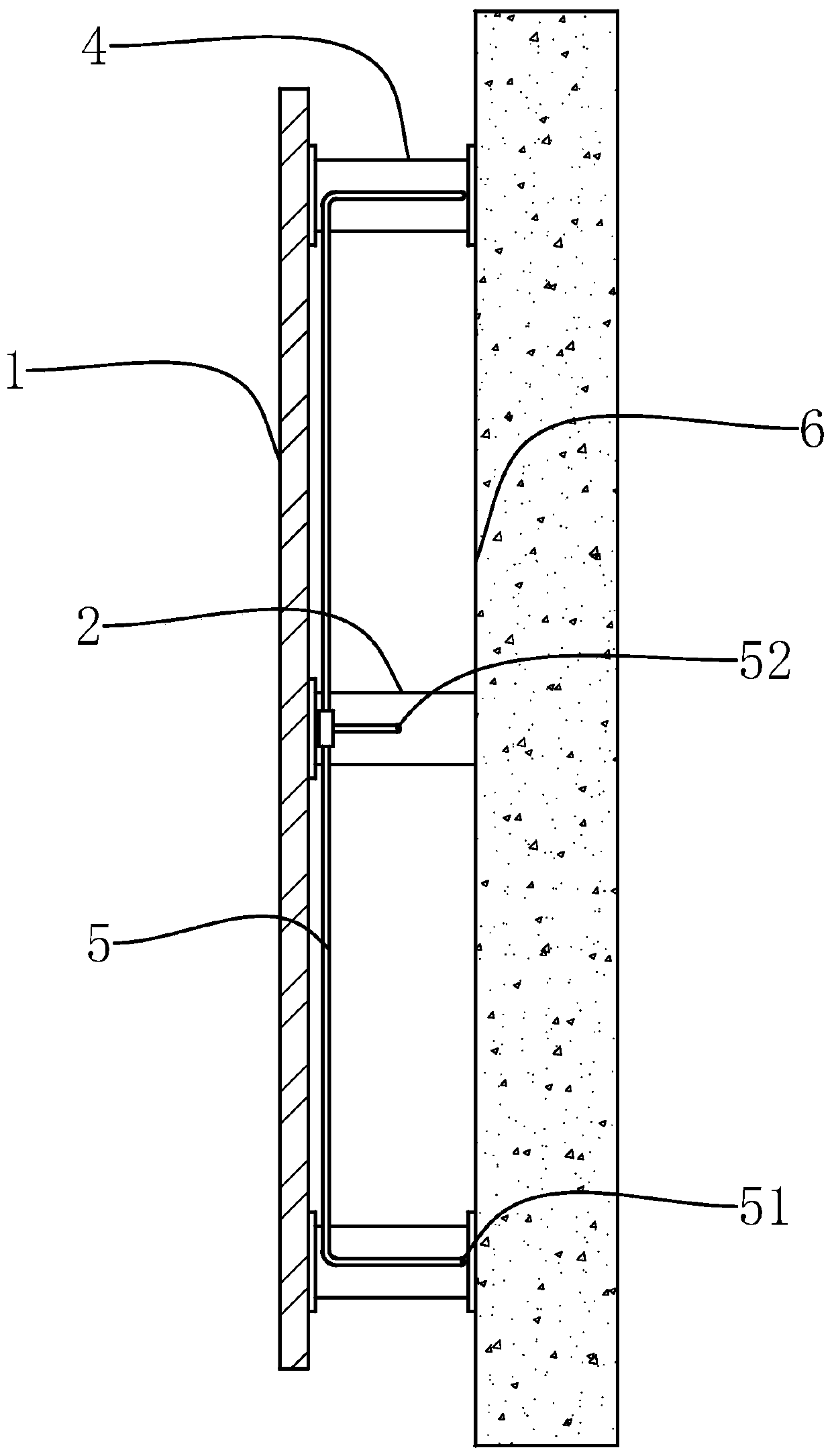

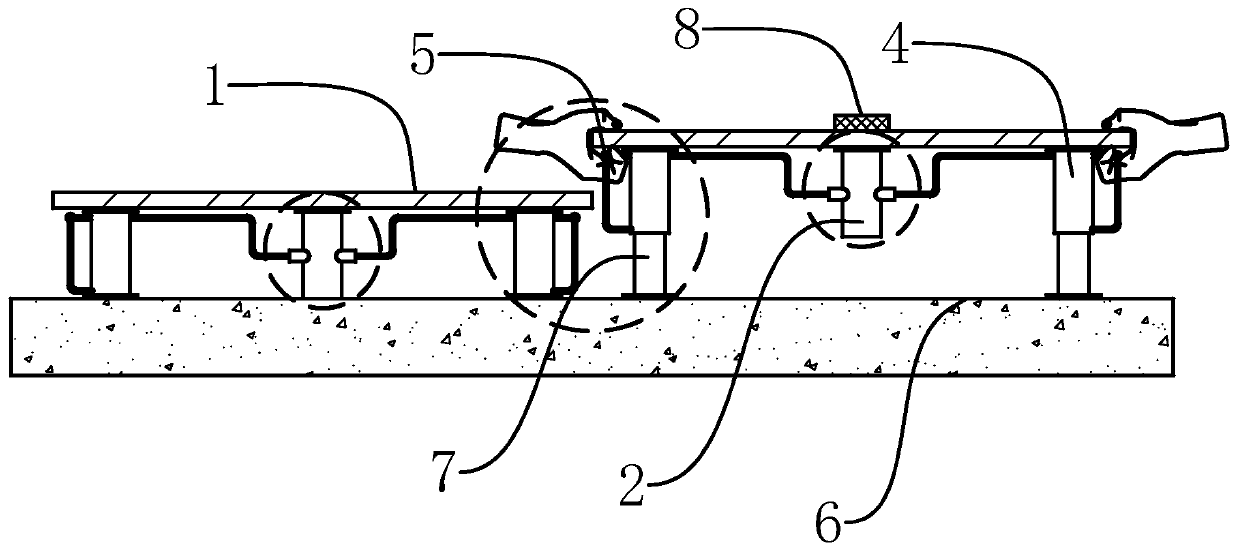

[0041] Such as Figure 1-6As shown, a glass curtain wall of the present invention includes a wall panel 1 connected to the wall surface 6 through a fixing device. The wall panel 1 is made of tempered glass material and has a rectangular plate structure. The fixing device includes a The front fixing part, and the rear fixing part connected with the wall surface 6, the front fixing part includes the push sleeve 2 whose front end is fixed on the center position of the inner side of the wall panel 1, the axis of the push sleeve 2 is perpendicular to the inner side of the wall panel 1, and the push sleeve 2 The rear end is fixed with a push plate 21, the outer wall of the push sleeve 2 is fixed with two reset sleeves 22, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com