A Fixing Device for Adjustable Pipeline Flux Leakage Detection Probe

A technology of magnetic flux leakage detection and fixing device, which is applied in the direction of pipeline system, machine/support, supporting machine, etc., can solve the problems of inconvenient use, inaccurate detection results, and the detection probe cannot detect pipelines, and achieves the reduction of friction, The effect of increasing the detection range and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

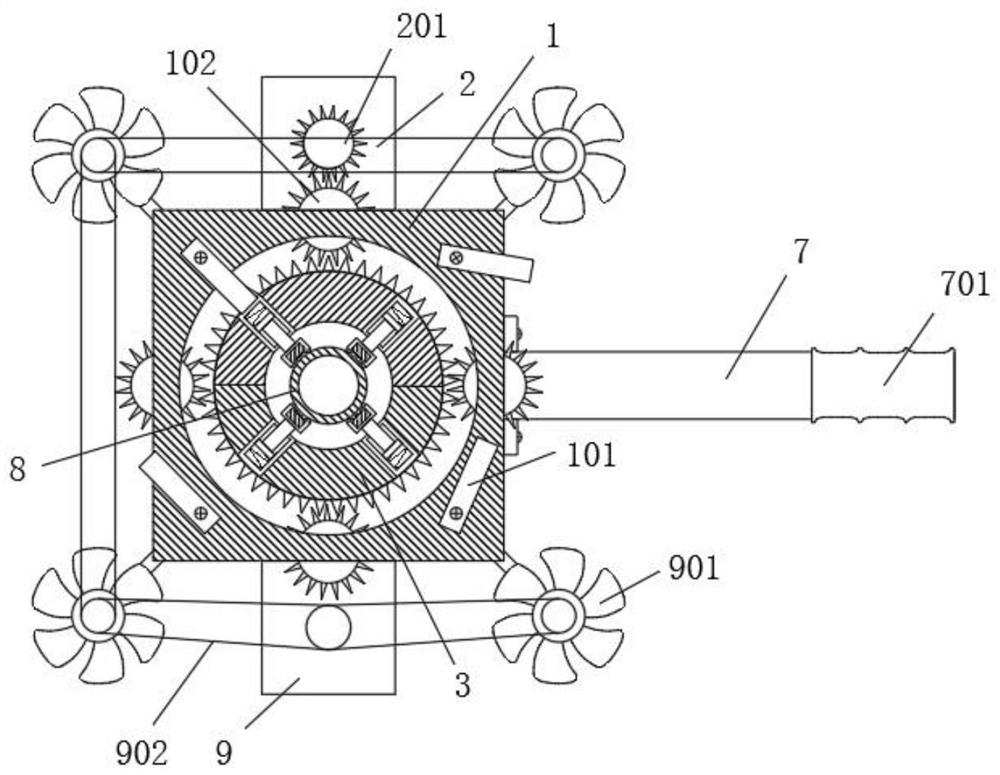

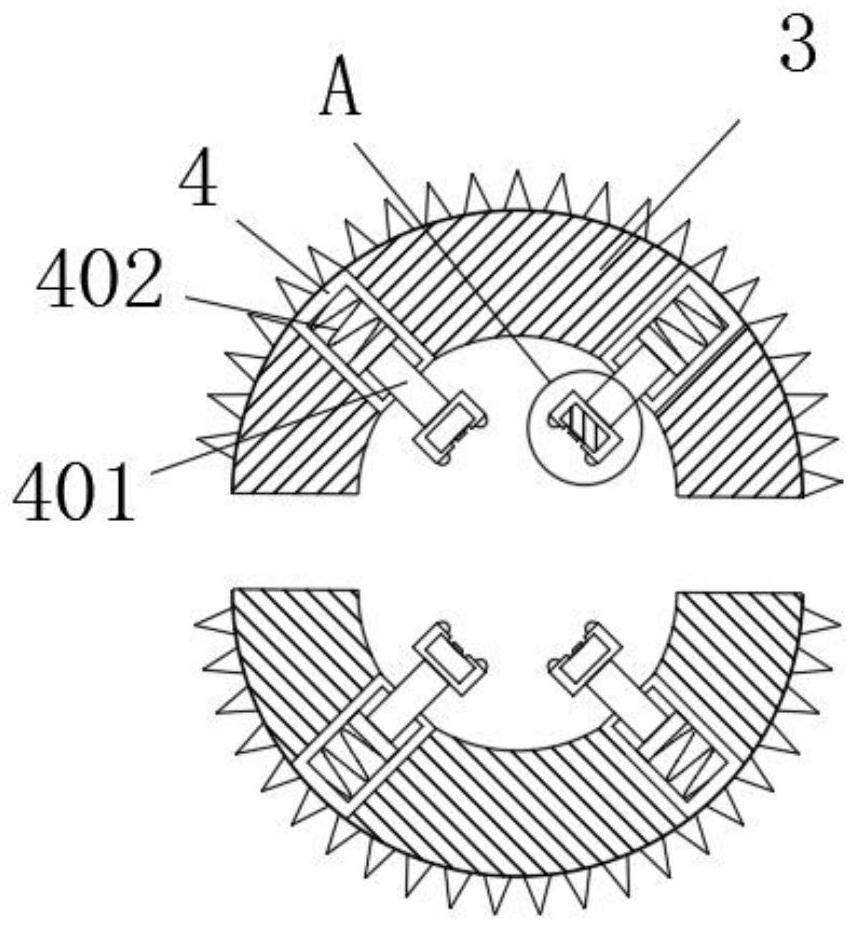

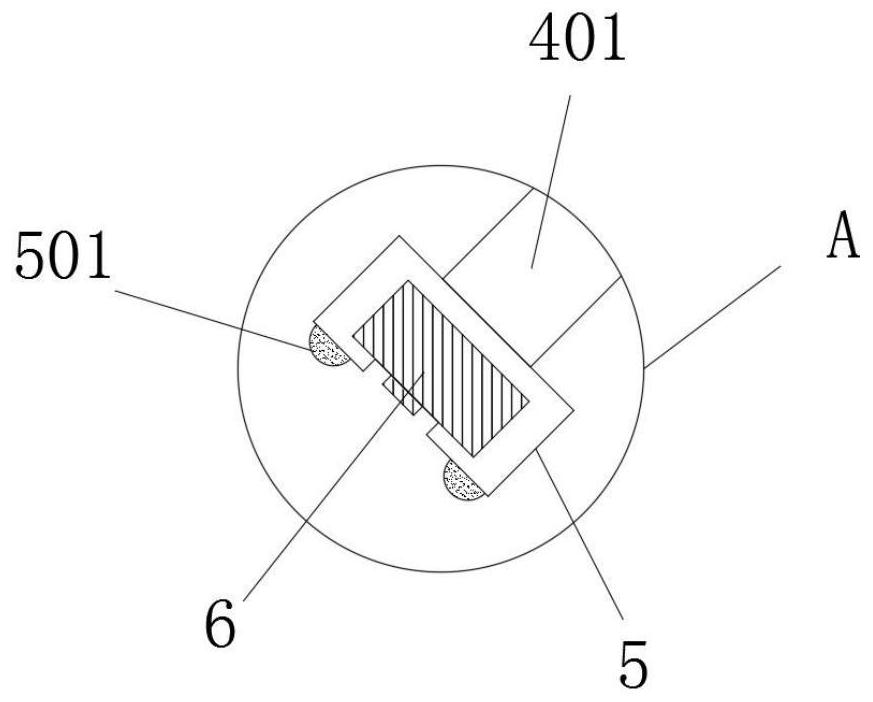

[0021] see Figure 1-2 , a fixing device for an adjustable pipeline magnetic flux leakage detection probe, comprising an outer casing 1 and a rotating detection mechanism installed inside the outer casing 1 for detecting magnetic flux leakage of a pipeline 8 and a rotating detection mechanism arranged on the outer casing 1 for supporting the rotating detection mechanism The second gear 102, the rotation detection mechanism includes a semi-circular ring 3, the interior of the semi-circular ring 3 is inlaid with a limit block 4, the limit block 4 is provided with a chute, and the sliding card in the chute is provided with a slider 401 , one end of the slider 401 is elastically connected to the bottom of the limit block 4 through a spring, and the other end of the slider 401 is fixedly installed with the installation block 5, please refer to image 3 , the installation block 5 is provided with an installation groove and an opening is provided on the installation block 5, a magnet...

Embodiment 2

[0029] In order to facilitate the application of this device to detect pipelines in water, this embodiment has been further improved on the basis of embodiment 1. Compared with embodiment 1, the main difference is that: the outer jacket 1 is also provided with a second Two drive motors 9 and fan blades 901, the second drive motor 9 is fixedly installed on the overcoat 1, the second drive motor 9 and the fan blades 901 are connected by belt transmission, after the device is sleeved on the pipeline 8 in the water, Start the second drive motor 9 to drive the fan blade 901 to rotate, which can drive the device to move along the pipeline 8. At the same time, the device will rotate on the pipeline 8 during the movement of the device driven by the fan blade 901, so there is no need to start the first A drive motor 2 drives the rotation detection mechanism to rotate, saving power consumption.

[0030] The installation number and installation position of the fan blades 901 on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com