Cold-chain coolant for tunas and preparation method of cold-chain coolant

A cool storage agent, tuna technology, applied in chemical instruments and methods, preservation of meat/fish by freezing/cooling, materials for heat exchange, etc. The effect of reducing the amount of use, not easy to break the packaging bag, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

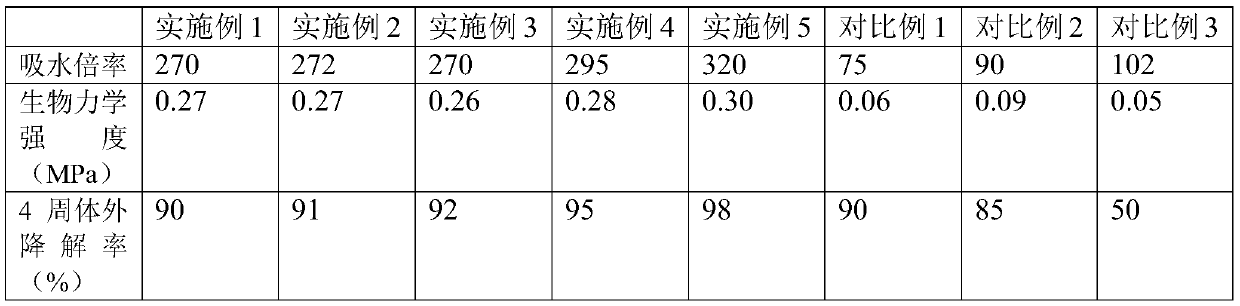

Examples

Embodiment 1

[0033] Composition of raw materials (parts by weight): 1 part of dry polyaspartic acid / sodium alginate / hyaluronic acid triple network hydrogel, 5 parts of sodium chloride, and 77 parts of water.

[0034] The dried polyaspartic acid / sodium alginate / hyaluronic acid triple network hydrogel was prepared by the following method:

[0035] S1. Preparation of the first gel network: dissolve 10g polyaspartic acid, 3g arginine, 12g sodium alginate and 8g hyaluronic acid in water, stir well, add 5g carbodiimide hydrochloride and 2g N-hydroxysuccinyl, after being stirred evenly, left to stand to form a gel to obtain hydrogel A;

[0036] S2. Preparation of the second gel network: soak the above hydrogel A in 2mol / L CaCl 2 solution, soaked for 24 hours and then taken out to obtain hydrogel B;

[0037] S3. Preparation of the third gel network: Dissolve 7g of polyethylene glycol in NaOH solution, heat to 35°C, add 0.4g of divinyl sulfone, react in ice bath, heat to 80°C for 2min after the r...

Embodiment 2

[0041] Composition of raw materials (parts by weight): 1 part of dry polyaspartic acid / sodium alginate / hyaluronic acid triple network hydrogel, 5 parts of sodium citrate, and 77 parts of water.

[0042] The dried polyaspartic acid / sodium alginate / hyaluronic acid triple network hydrogel was prepared by the following method:

[0043] S1. Preparation of the first gel network: dissolve 10g polyaspartic acid, 3g arginine, 12g sodium alginate and 8g hyaluronic acid in water, stir well, add 5g carbodiimide hydrochloride and 2g N-hydroxysuccinyl, after being stirred evenly, left to stand to form a gel to obtain hydrogel A;

[0044] S2. Preparation of the second gel network: soak the above hydrogel A in 2mol / L CaCl 2 solution, soaked for 24 hours and then taken out to obtain hydrogel B;

[0045] S3. Preparation of the third gel network: Dissolve 7g of polyethylene glycol in NaOH solution, heat to 35°C, add 0.4g of divinyl sulfone, react in ice bath, heat to 80°C for 2min after the reac...

Embodiment 3

[0049] Composition of raw materials (parts by weight): 1 part of dry polyaspartic acid / sodium alginate / hyaluronic acid triple network hydrogel, 4 parts of sodium chloride, 1 part of sodium citrate, and 77 parts of water.

[0050] The dried polyaspartic acid / sodium alginate / hyaluronic acid triple network hydrogel was prepared by the following method:

[0051] S1. Preparation of the first gel network: dissolve 10g polyaspartic acid, 3g arginine, 12g sodium alginate and 8g hyaluronic acid in water, stir well, add 5g carbodiimide hydrochloride and 2g N-hydroxysuccinyl, after being stirred evenly, left to stand to form a gel to obtain hydrogel A;

[0052] S2. Preparation of the second gel network: soak the above hydrogel A in 2mol / L CaCl 2 solution, soaked for 24 hours and then taken out to obtain hydrogel B;

[0053] S3. Preparation of the third gel network: Dissolve 7g of polyethylene glycol in NaOH solution, heat to 35°C, add 0.4g of divinyl sulfone, react in ice bath, heat to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap