Photographic device capable of automatically cleaning camera

A photographic device and automatic cleaning technology, applied to the cleaning method using gas flow, image communication, cleaning method and utensils, etc., can solve the problems affecting the high-quality cleaning of the wiping cloth, the rapid adsorption of dust, and the ineffective cleaning, etc., to achieve Reduce manual repeated wiping action, easy to install and use, soft and delicate material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

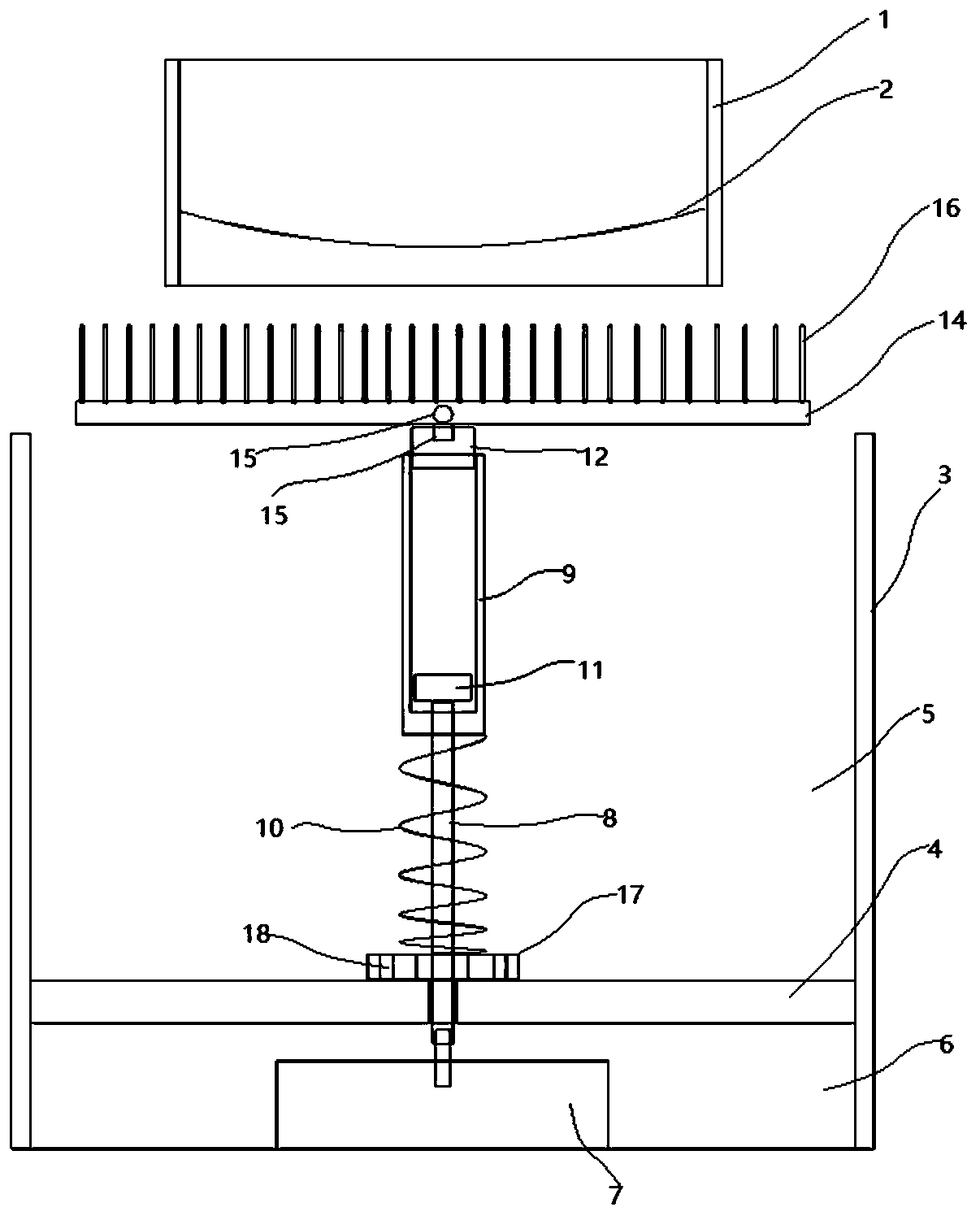

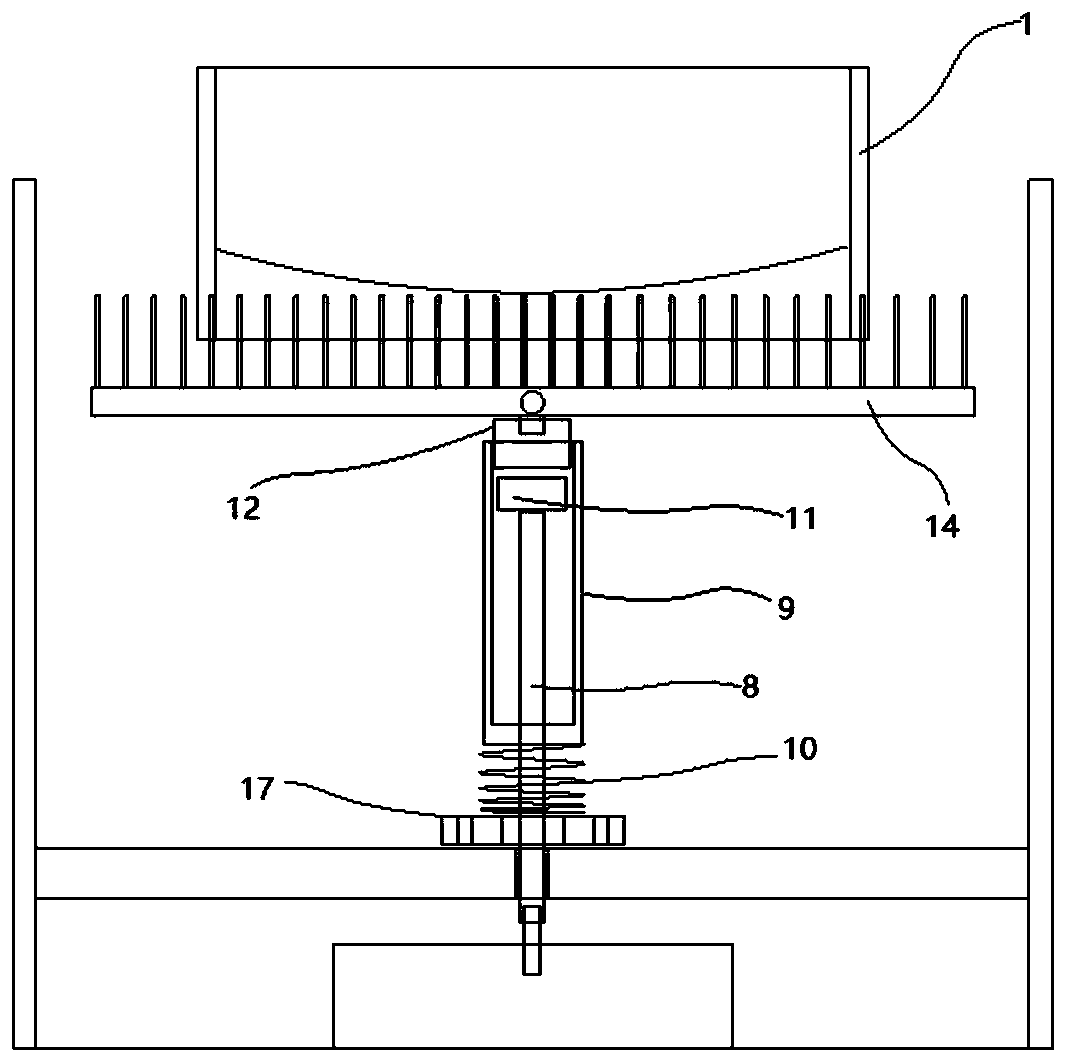

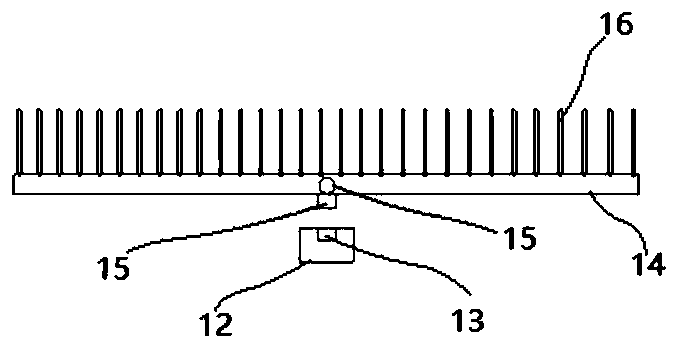

[0028] Such as Figure 1-8 As shown, a photographic device capable of automatically cleaning the camera includes a camera lens; the camera lens includes a casing 1 and a lens sheet 2; it is characterized in that: the casing 1 is fitted with a cleaning device; the cleaning device includes a casing 1 The carrying barrel 3 is connected to the set; the lower part of the carrying barrel 3 is provided with a partition 4; the partition 4 divides the interior of the carrying barrel 3 into upper and lower parts, the upper part is the cleaning chamber 5, and the lower part is the installation chamber 6; the middle part of the installation chamber 6 is installed There is a driving motor 7; the output end of the driving motor 7 is connected with a vertical transmission rod 8; the transmission rod 8 seals and passes through the partition plate 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com