Gap measuring device and application thereof to gap measurement of four doors and two covers of automobile

A measuring device and gap technology, applied in the direction of measuring devices, mechanical measuring devices, electromagnetic measuring devices, etc., can solve the problems of difficult to guarantee measurement accuracy, impossible to measure, limited thimble length, etc., to save preparation time, wide use range, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

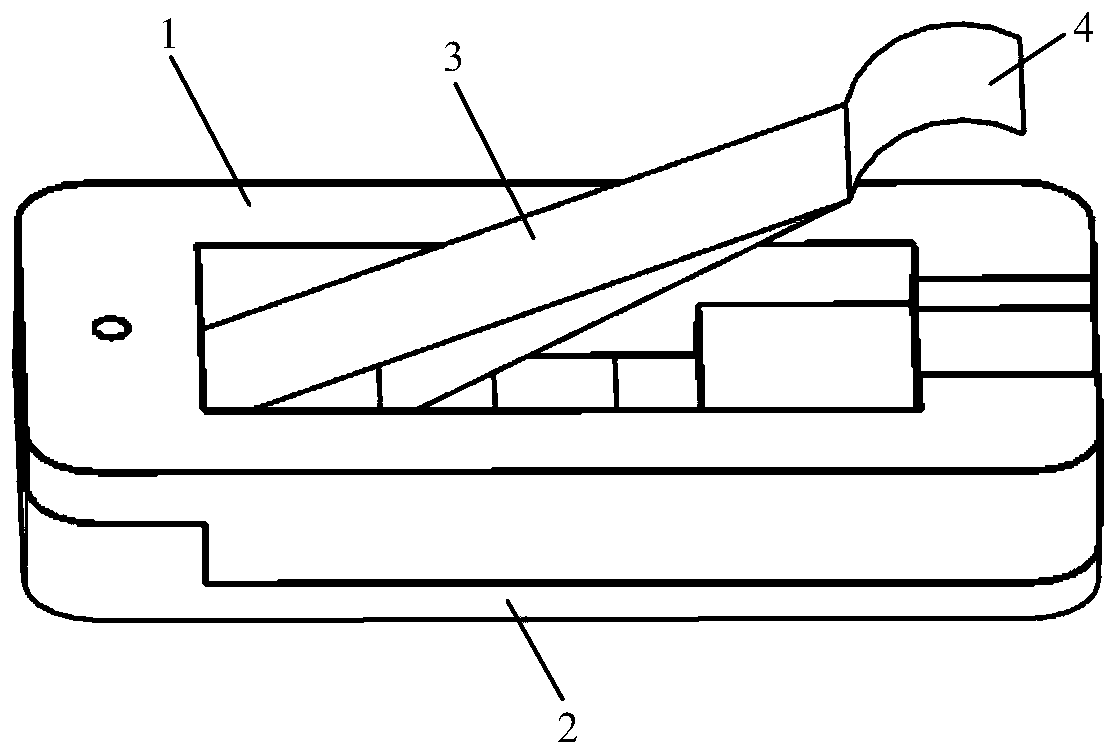

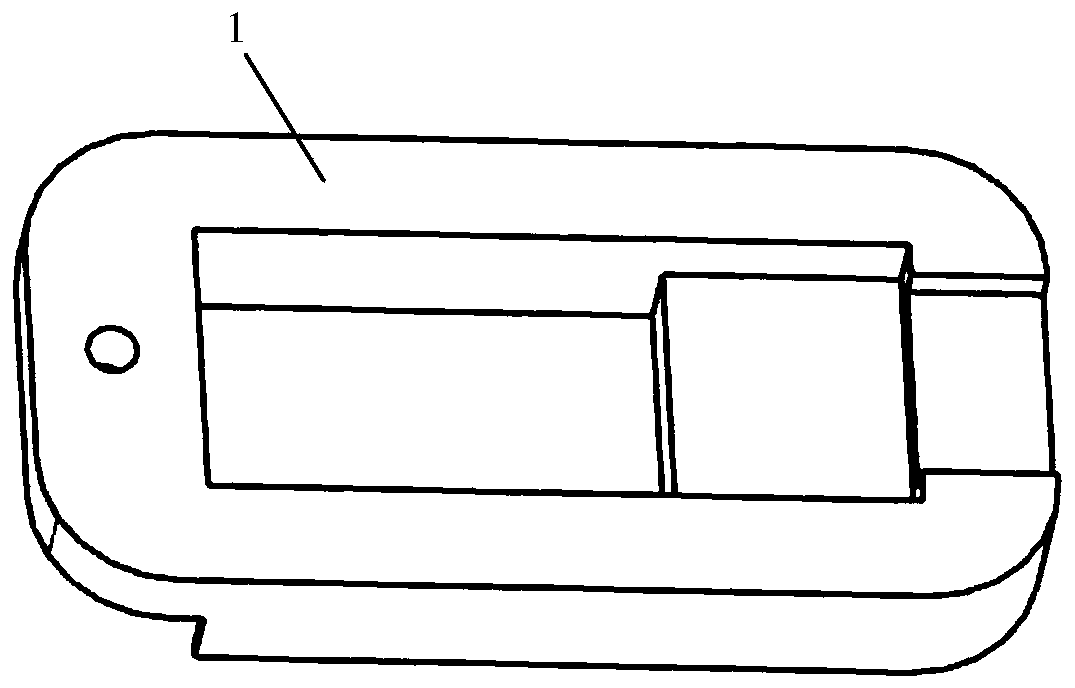

[0037] A gap measuring device consisting of a fixed upper part and a lower part;

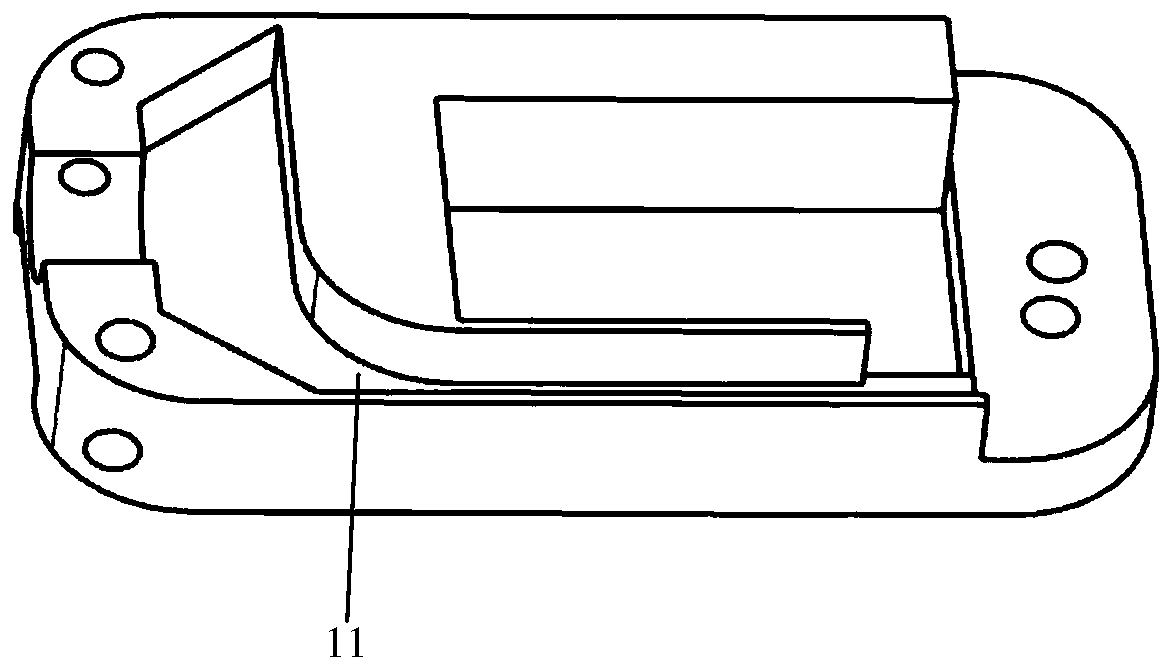

[0038] The upper part includes an upper housing 11, a second copper sheet 4 and a patch sensor, and the second copper sheet 4 includes a second copper sheet fixing part 41 integrally connected in sequence and a second copper sheet with restoring force Bending part 42, the angle between the second copper sheet fixing part 41 and the second copper sheet bending part 42 is a second obtuse angle; the patch sensor is pasted and fixed on the second copper sheet bending part 42 on the upper surface;

[0039] The lower part includes a lower casing 2 and a positioning member located in the lower casing 2 for fixing at the gap;

[0040] The second copper sheet fixing part 41 extends between the upper casing 1 and the lower casing 2 and is clamped and fixed by the upper and lower casings.

[0041] Wherein, the patch sensor occupies a small space, and is specifically a strain gauge 5, preferably, the mode...

Embodiment 2

[0050] On the basis of embodiment 1, a gap measuring device is respectively placed at two positions of the car door gap, named as sensor 1 and sensor 2 respectively, as Figure 7 As shown, the two sensors are calibrated using a standard device and an eDAQ data acquisition instrument. The standard curve of the relationship between strain and displacement of sensor 1 is shown in Figure 8 Shown; The standard curve of the strain and displacement relationship of sensor 2 is as Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com