A control technology for layered salt rock selective solution mining cavity creation

A selective, salt-rock technology that can be used in fluid production, earth-moving drilling, wellbore/well components, etc., and can solve problems such as the influence of thick interlayers on the stability of the salt cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

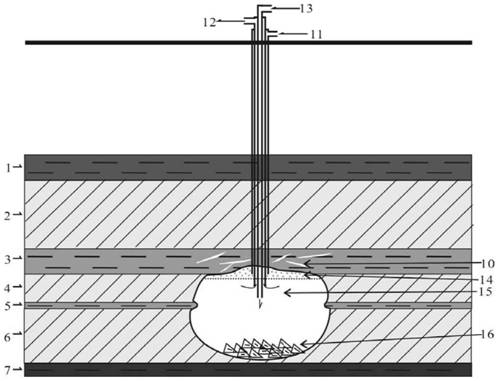

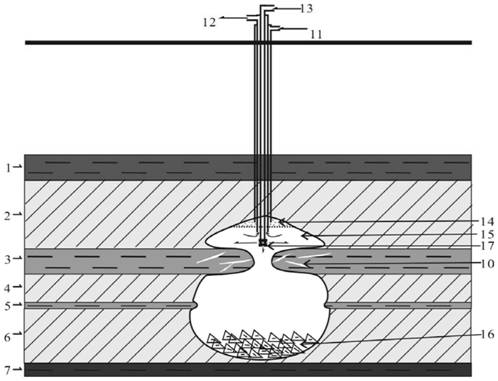

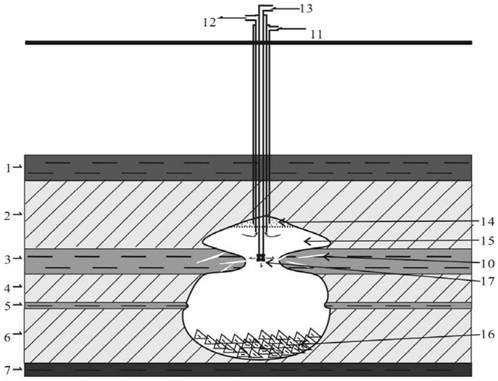

[0065] (1) Drill a single well from the surface. In the drilling stage, firstly drill the hole to the bottom of the salt rock. Through sidetracking and other methods, a series of side holes 9 are formed inside the thick interlayer, and then through small-scale fracturing, so that effective holes and connected fractures 10 are formed inside the thick interlayer, such as figure 1 , figure 2 shown.

[0066] (2) After the thick interlayer pores and fractures are formed, the salt rock in the lower part of the thick interlayer is mined to make full use of the salt rock resources and provide space for the interlayer collapse.

[0067] (3) When the salt rock in the lower part of the thick interlayer is mined, water is mainly injected through the center pipe 13 of Φ114mm, and the brine is extracted from the annular space between the center pipe 12 and the center pipe 13 of Φ177.8mm, and the salt rock is mined from the bottom of the salt rock layer to form a small area Dissolving cav...

Embodiment 2

[0074] (1) Drill two wells from the surface, one vertical well 18, one horizontal butt well 19, and the distance between the two wells is 200m. In the process of solution production in the opposite well, there are Φ244.5mm technical casing and Φ177.8mm intermediate pipe in the well.

[0075] (2) After the drilling is completed, through physical action, holes and fractures 10 are formed in the thick interlayers around the wellbore of the two wells, which mainly include: single wellbore for fracturing the interlayer; through sidetracking, horizontal wells are drilled in the interlayer, A series of side holes 9 are formed inside the interlayer, and then through small-scale fracturing, the interlayer forms effective holes and connected fractures 10 within a certain range, such as Figure 7 shown.

[0076] (3) After the pores and fractures of the thick interlayer are formed, the salt rock in the lower part of the thick interlayer is mined. When mining the salt rock below the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com