Submersible electric pump mounting base

A submersible electric pump and mounting seat technology, applied in the direction of the pump, the components of the pumping device for elastic fluid, the pump element, etc., can solve the problems of complicated operation, impact, pump body or personal injury, etc., and achieve simple installation and operation. , Reduce the impact force and ensure the effect of fixed position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

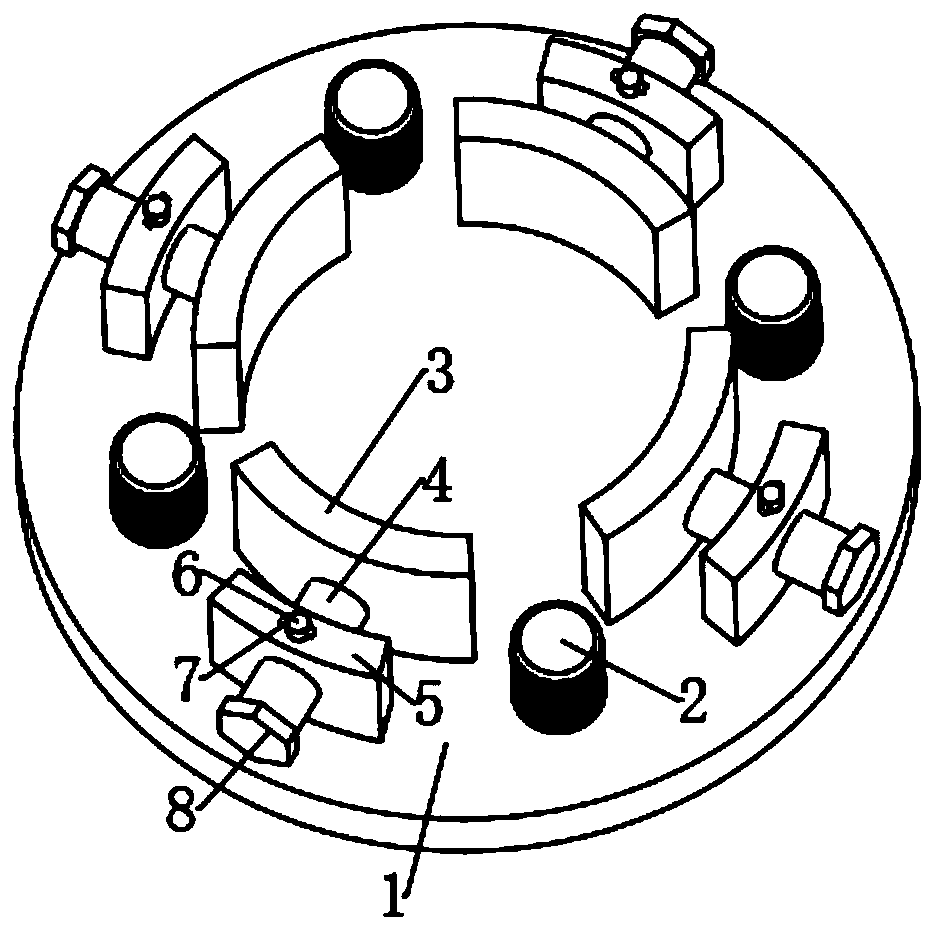

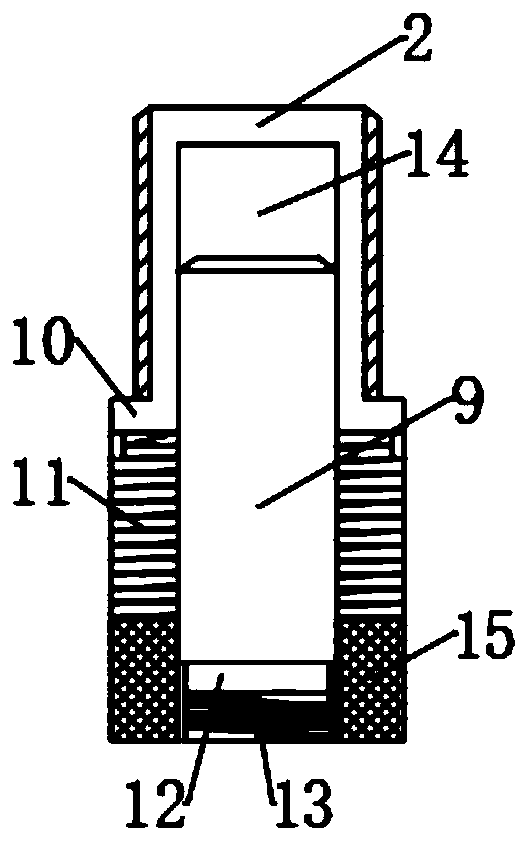

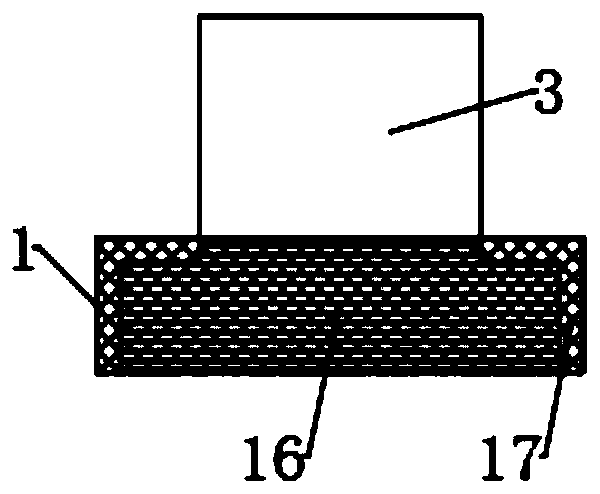

[0020] see Figure 1-3 , a submersible electric pump installation seat, including a workbench 1, the cross section of the workbench 1 is circular, and the upper end surface of the workbench 1 is evenly provided with a plurality of arc-shaped fixing plates 3, and the fixing plates 3 deviate from the center of the workbench 1 An operating mechanism is arranged on one side, and the fixed plate 3 can move back and forth to the center of the workbench 1 through the operating mechanism to fix the submersible electric pump; a plurality of positioning pins 2 are evenly arranged on the periphery of the interval area of the fixed plate 3, and the positioning The pin 2 is provided with a damping mechanism. The specific structure of the operating mechanism is not limited. Preferably, in this embodiment, the operating mechanism includes a limit plate 5, which is arranged on the side of the fixed plate 3 away from the center of the workbench 1. The limit plate The central position of 5 i...

Embodiment 2

[0029] see Figure 4 , in embodiment 1, since the positioning pin 2 is clamped with the lower end of the submersible pump to determine the installation position of the pump body, it is necessary to ensure that the pump body is located at the center of the workbench 1 during the clamping process, so the operation is inconvenient; therefore, This embodiment is improved on the basis of Embodiment 1. The improvement is: a positioning column 18 is arranged at the center of the workbench 1, and the positioning column 18 matches the shape of the inner cavity of the pump body so as to facilitate confirmation of the placement of the pump body Position, improve the installation efficiency of the pump body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com