Wireless temperature measurement insulation plug of cable head, and working method thereof

A wireless temperature measurement and cable head technology, which is applied to thermometers, electrical components, measuring devices, etc., can solve the problem of inability to accurately understand the partial discharge of elbow cable heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

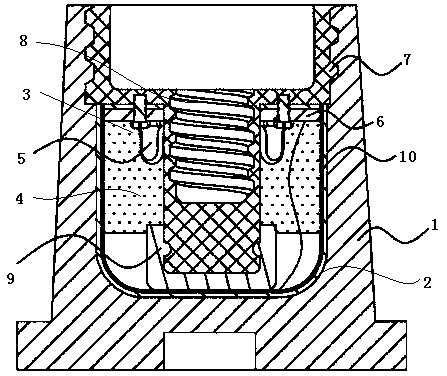

[0018] Such as figure 1 As shown, a cable head wireless temperature measurement insulation plug includes an epoxy insulation plug 1, and the epoxy insulation plug is provided with a columnar groove 2 from the upper surface downward, and a wireless temperature measurement is fixed in the columnar groove. Body 3, the wireless temperature measurement body includes a potential difference induction power-taking module 4 fixed in a columnar groove, a wireless transmission module 5 and a temperature measurement module 6, and the upper end of the epoxy insulating plug is inserted into the elbow cable head And through the shielding cap 7 embedded in the columnar groove and the fixing bolt 8 fixed in the elbow cable head, the wireless temperature measuring body and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com