Underground high voltage cable junction box

A technology of high-voltage cables and junction boxes, applied in the direction of electrical components, etc., can solve the problems of poor sealing, flushing, and unsightly appearance, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

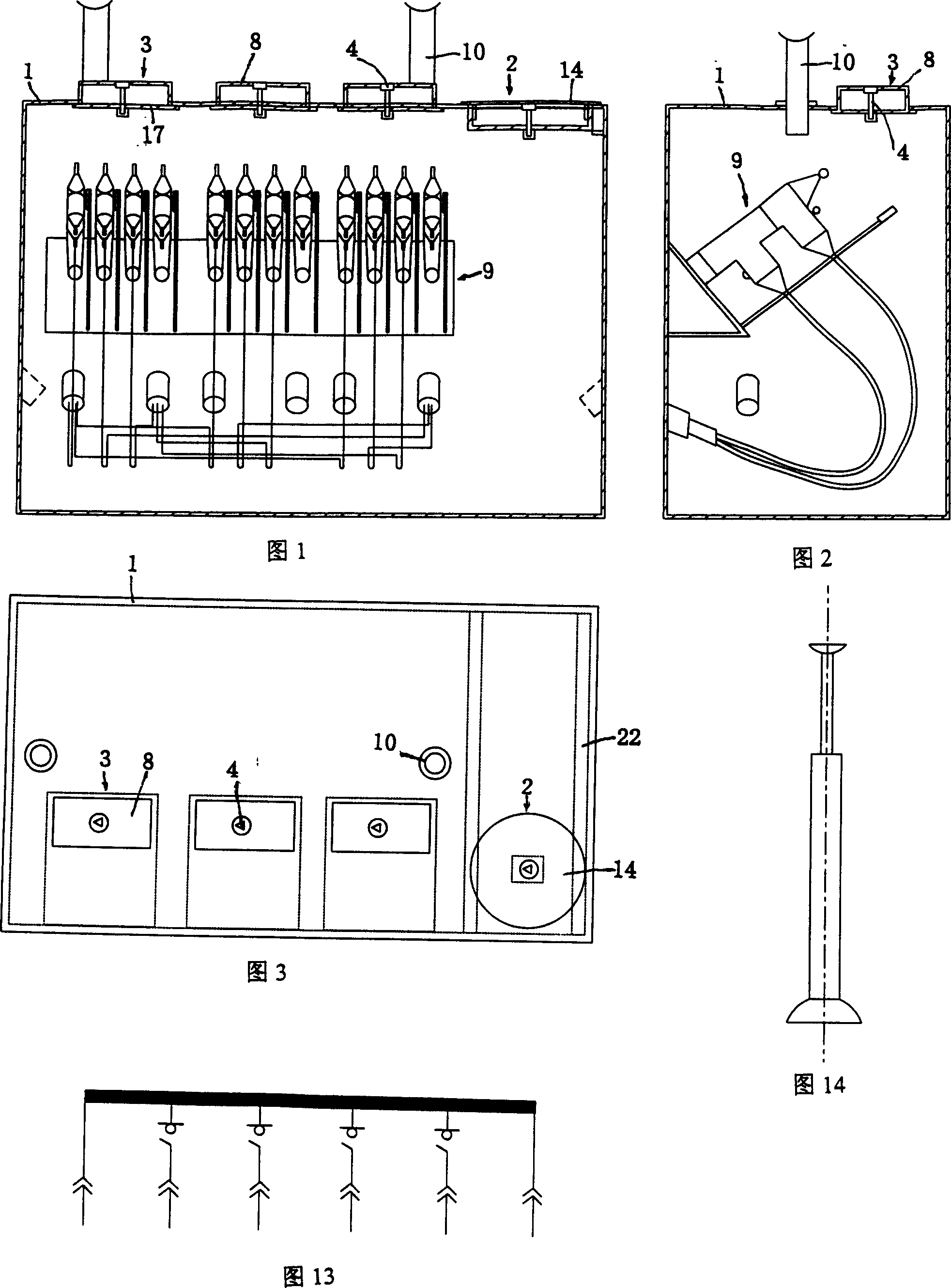

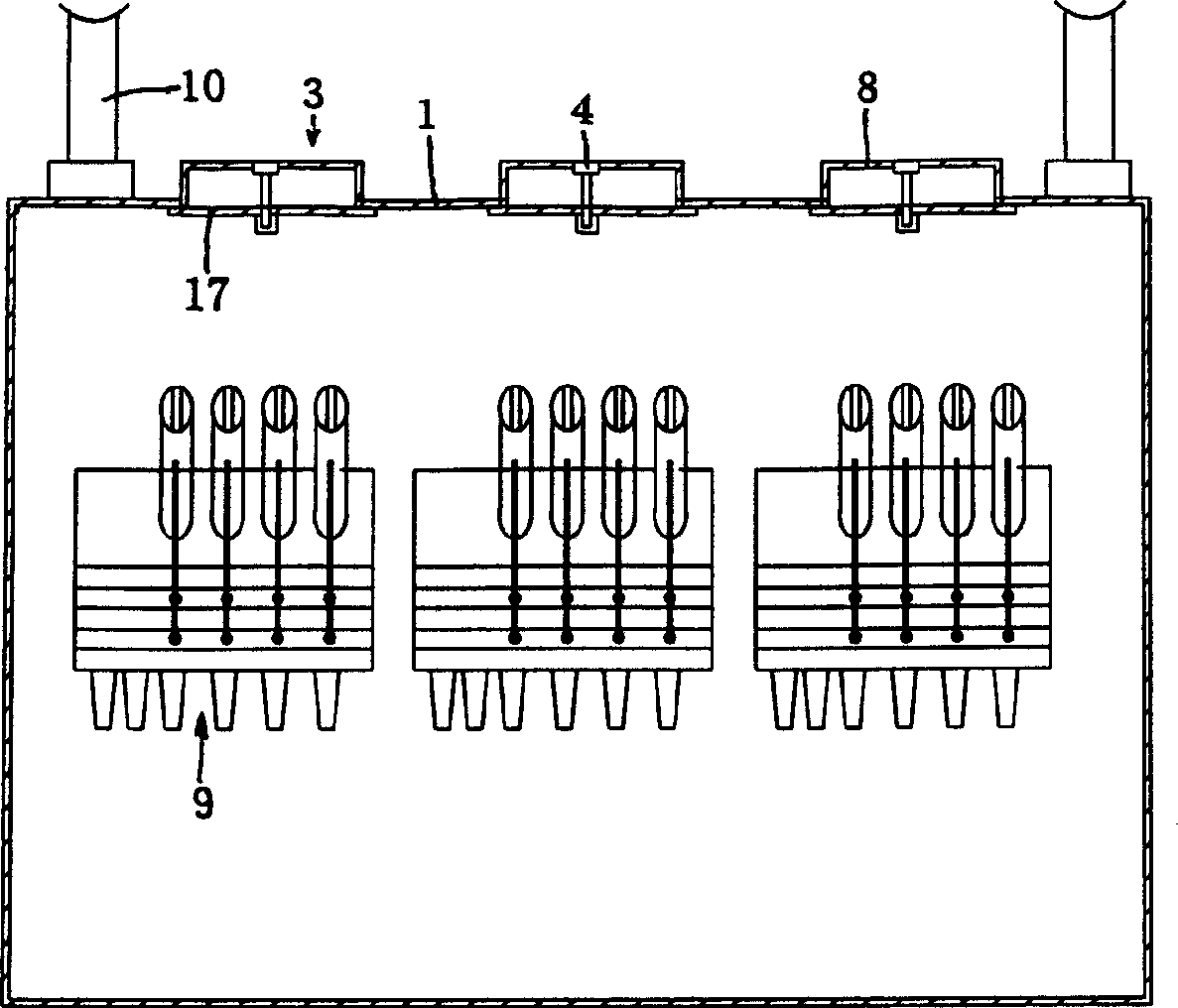

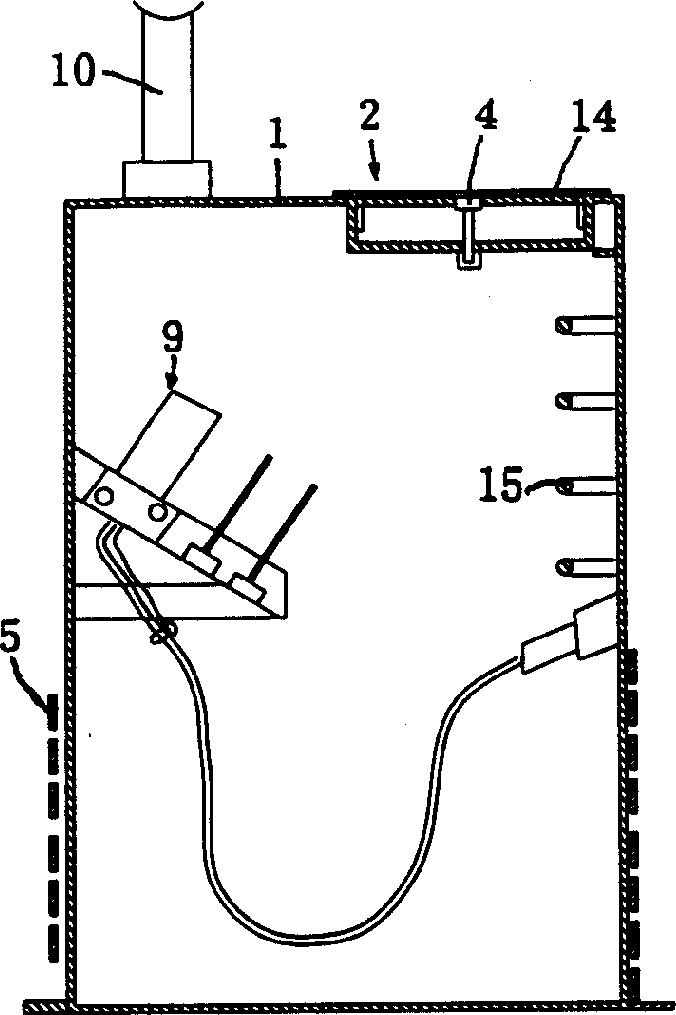

[0036] From Figure 1, Figure 2, Figure 3, Figure 4 , Figure 5 , Fig. 6 and Fig. 11 can find out that the underground high-voltage cable distribution box of the present invention comprises the box body 1 that welds with steel plate, and the bottom of box body 1 is provided with cable inlet and outlet pipe, and cable inlet and outlet pipe pass through If there is a cable, a semicircular pressure plate can be used to press the cable at the inlet and outlet pipes of the cable, and then the bolts of the pressure plate are tightened and the sealing packing is injected to fix the cable tightly on the top of the box 1 described in the cable inlet and outlet pipes. Underground, the top of the box body 1 is provided with a manhole 2, two explosion-proof holes and three switch operation holes 3, the manhole 2 is sealed with a manhole cover, and the box body 1 is located below the manhole 2 A ladder 4 is provided so that when it is necessary to repair the electrical appliances in the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com