Adjustable double-punch device for punching point riveting

An adjustable, double-punch technology, applied in the field of processing equipment, can solve problems such as poor processing quality, parts flying out, and low processing efficiency, and achieve the effects of preventing damage and safety accidents, enhancing stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation, structure, features and functions of the adjustable double-punch device for punch point riveting according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

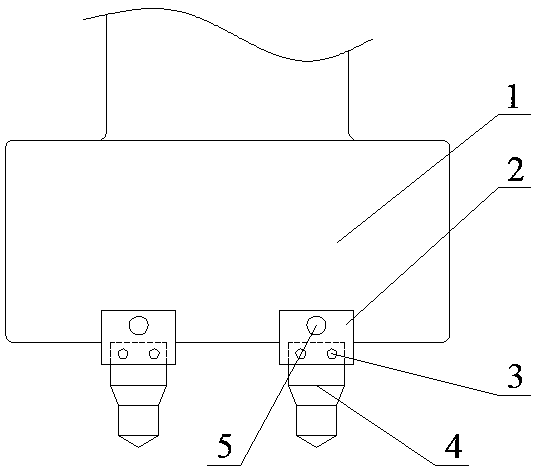

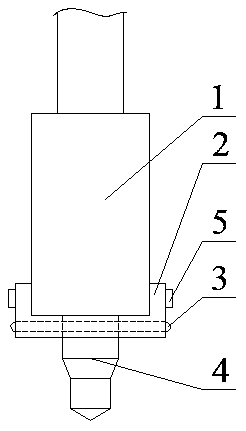

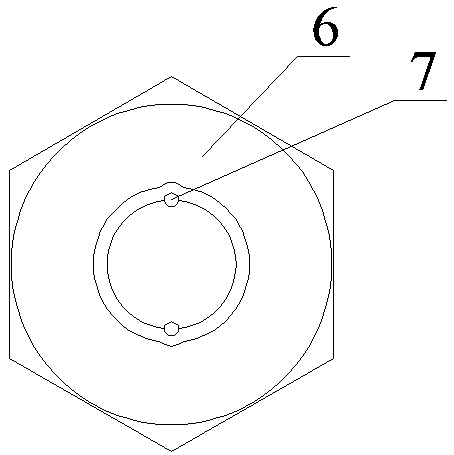

[0017] see Figure 1 to Figure 2 , the adjustable double-punch device for punch point riveting of the present invention includes a punch handle 1, a clamping sleeve 2, and a punch 4, wherein: the bottom of the punch handle 1 is movably connected with a clamping sleeve 2, and A punch 4 is detachably installed on the jacket 2 . The clamping sleeve 2 is a right-angle U-shaped sleeve body, and the punch 4 is installed in the clamping sleeve 2 through the mounting pin 3 . The clamping sleeve 2 can move along the side of the punch handle 1, and both sides of the clamping sleeve 2 are fastened by locking bolts 5. The number of punches 4 is two. Each punch 4 is connected by two mounting pins 3 .

[0018] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com