Soakaway pit dewatering device and soakaway pit construction method

A puddle and water pump technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems that the cushion layer and waterproof layer cannot be closed in time, affect the foundation construction, damage the waterproof layer, etc., and achieve convenient construction, water level does not rise, Guaranteed waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

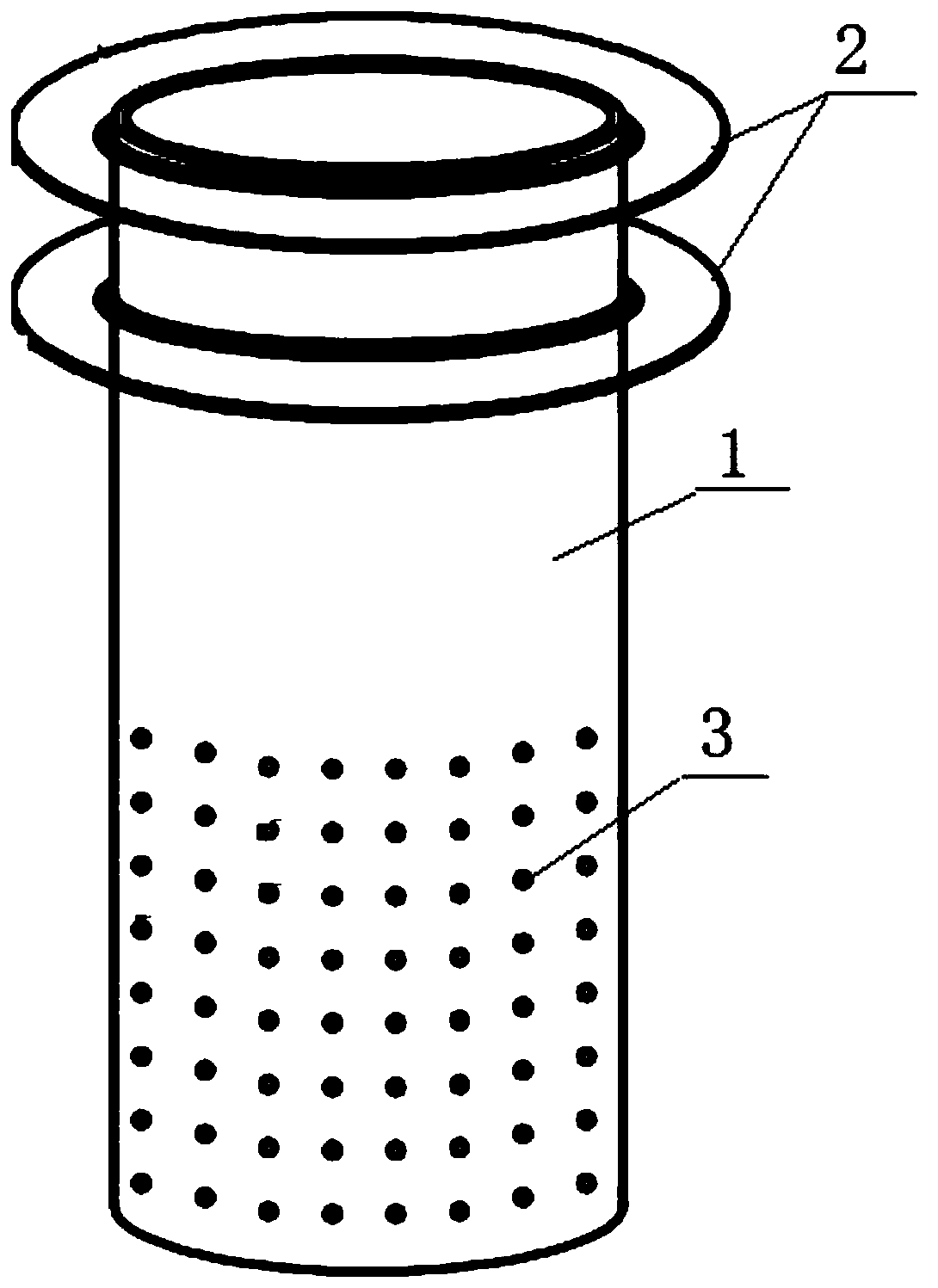

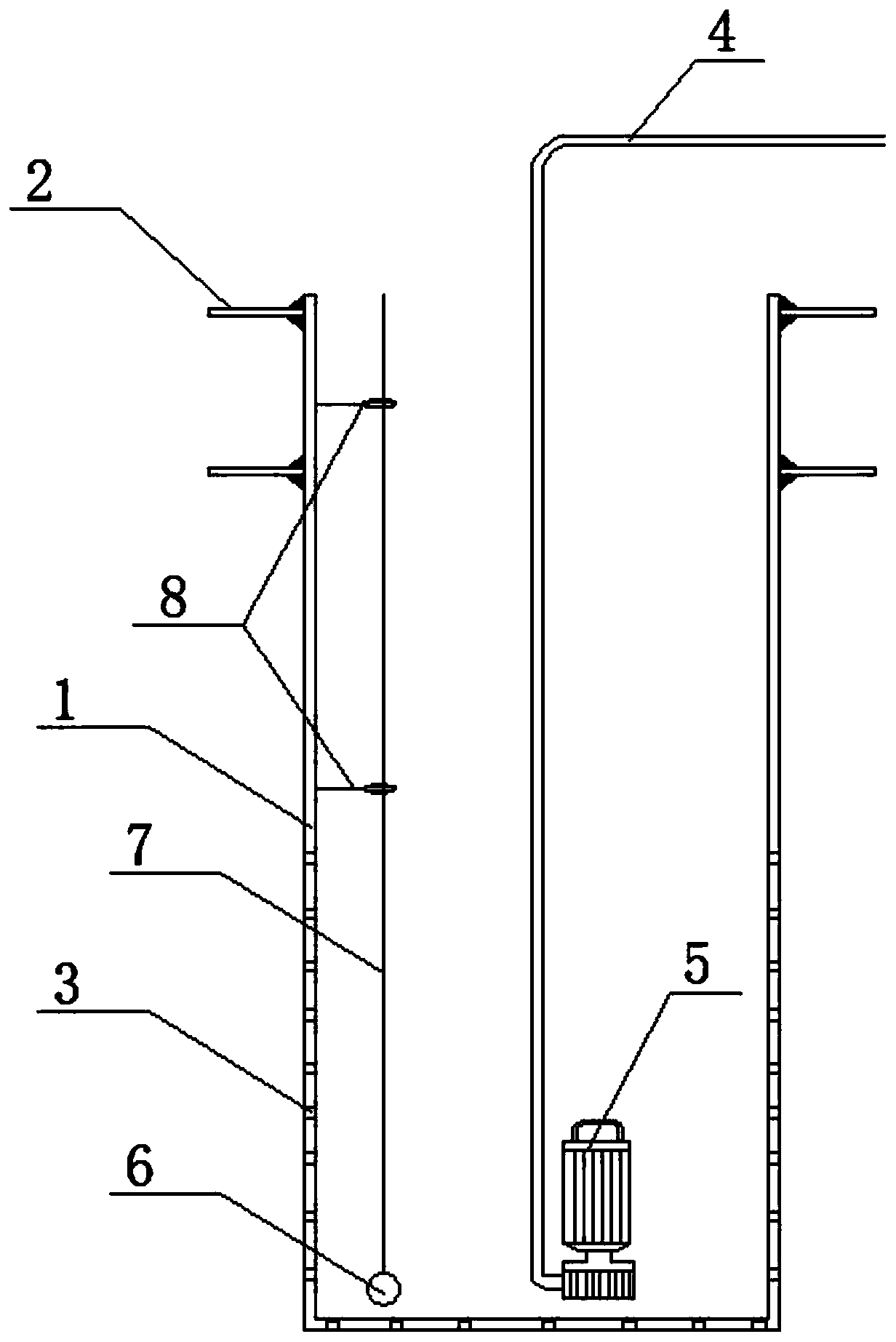

[0035] Such as Figure 1-2 As shown, a water seepage pit dewatering device according to an embodiment of the present invention is used to isolate impurities from the water pump 5 when the water seepage pit is dewatered, to prevent impurities from causing damage to the water pump 5, and to ensure that the water pump 5 can continue to operate. It includes a protective tube 1 with an opening at the top. The protective tube 1 is made of steel. The wall thickness of the protective tube 1 is 2-5mm. The protective tube 1 is provided with a suction pipe 4 extending to the bottom of the protective tube 1, and the water inlet end of the suction tube 4 is connected with Water pump 5, the water outlet extends to the outside of the protection cylinder 1. The water pump 5 is used to pump the water that penetrates into the protection cylinder 1. The water pump 5 is an automatic pump. When the water level is higher than the water pump 5, it automatically pumps water, and it stops when the water ...

Embodiment 2

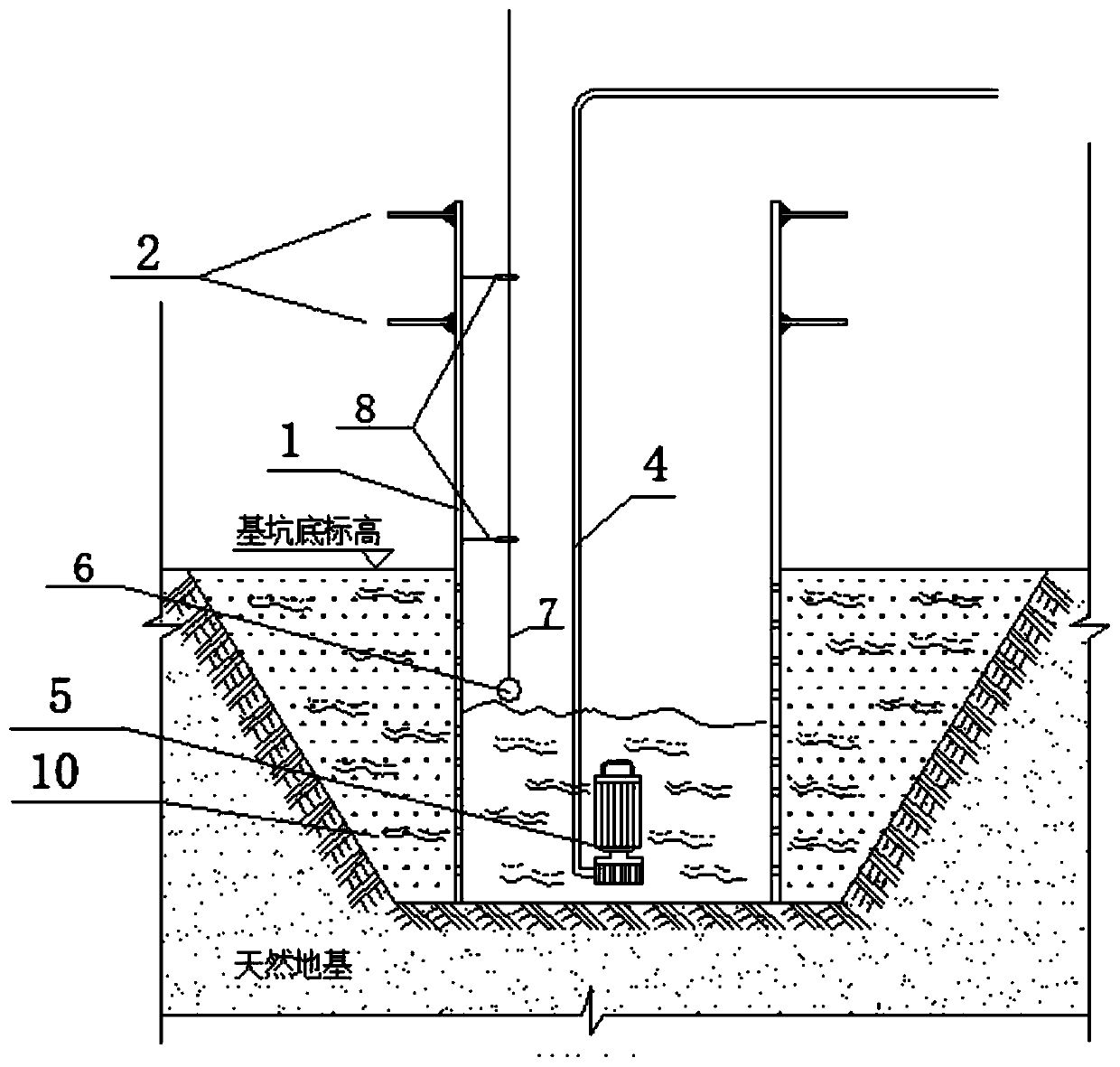

[0041] Such as Figure 3-6 As shown, a water seepage pit construction method includes the following steps:

[0042] S1: Install the soaking pit dewatering device in the center of the soaking pit, and fill the casing 1 with graded sand and gravel 10 to fix the casing 1. The graded sand and gravel 10 are used for dewatering, permeable and fixed casing 1, and the water pump 5 continues Pumping to keep the water level lower than the elevation of the bottom of the foundation pit;

[0043] S2: Pour the foundation concrete cushion 11 above the graded sand and gravel 10. The foundation concrete cushion 11 is poured to the outer wall of the protective tube 1, and the top of the foundation concrete cushion 11 is lower than the steel plate waterstop ring 2; the height of the general foundation concrete cushion Is 100mm.

[0044] S3: Lay the waterproof coiled material 12 above the foundation concrete cushion layer 11. The waterproof coiled material 12 is rolled up to the bottom of the steel wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com