Surface treatment method for resisting dewing environment of devices in spacecraft sealed cabin

A surface treatment and device surface technology, which is applied in the device for controlling the living conditions of spaceflight vehicles, spaceflight equipment, and spaceflight vehicles. Communication and other problems, to achieve the effect of solving line short circuit, good anti-condensation effect, ensuring life safety and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

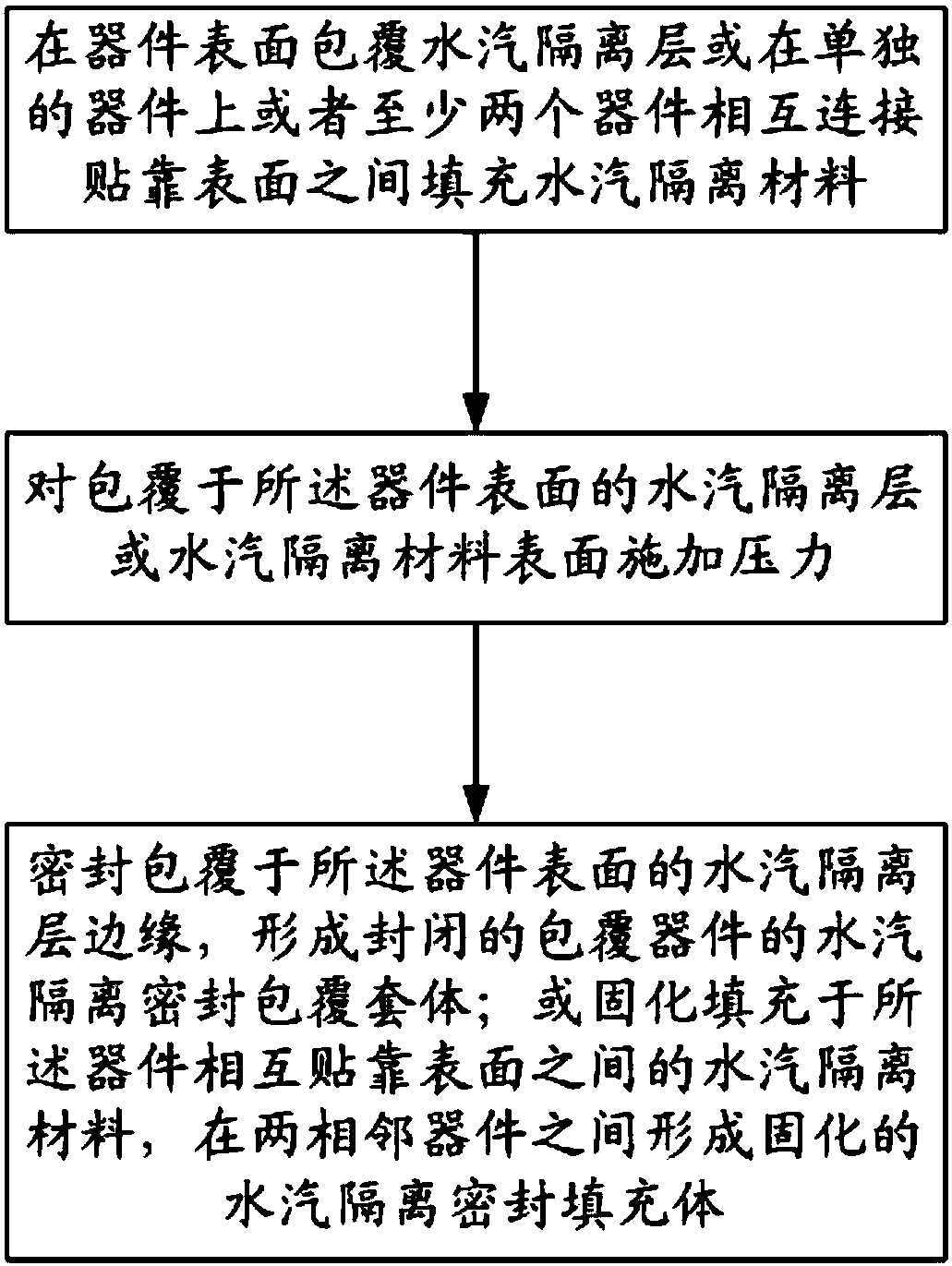

Method used

Image

Examples

Embodiment Construction

[0035] The description of the embodiments in this specification should be combined with the corresponding drawings, and the drawings should be regarded as a part of the complete specification. In the drawings, the shapes or thicknesses of the embodiments may be exaggerated and marked for simplification or convenience. Furthermore, the parts of each structure in the drawings will be described separately. It should be noted that the elements that are not shown in the drawings or described in words are forms known to those of ordinary skill in the art .

[0036] The descriptions of the embodiments here, any references to directions and orientations are just for convenience of description, and should not be construed as any limitation to the protection scope of the present invention. The following descriptions of the preferred embodiments involve combinations of features, which may exist independently or in combination, and the present invention is not particularly limited to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com