Lubricating medium coating mechanism of direct drive assembly device

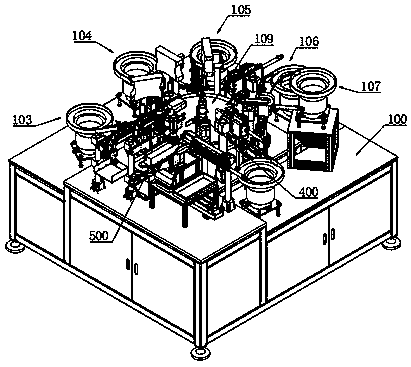

A technology of lubricating medium and assembling device, applied in the field of lubricating medium coating mechanism, can solve the problems of unsatisfactory efficiency and consistency, small volume of direct transmission group, difficult manual assembly, etc., and achieve efficient and reliable scientific assembly process and compact structure , to complete the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0048] one

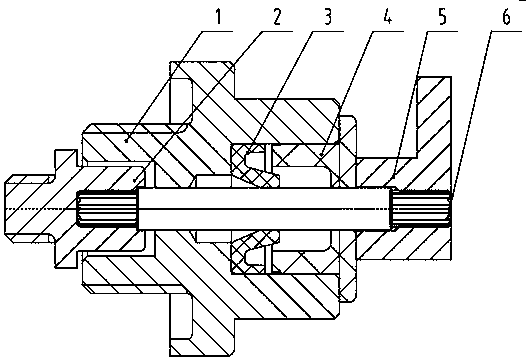

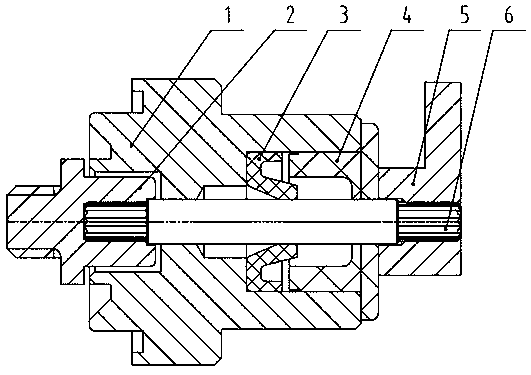

[0049] Such as figure 1 and figure 2 Shown: direct drive group, including drive shaft 6, bushing 1, dynamic seal structure, connecting piece 2 and lever 5;

[0050] The transmission shaft 6 is rotatably inserted in the sleeve 1; one axial end of the transmission shaft 6 is a transmission input end, and the other end is a transmission output end; the transmission input end is fixedly provided with the dial A rod 5, the shifting rod 5 has a shifting portion protruding outward along the radial direction of the transmission shaft 6; the transmission output end is coaxially fixed with the connecting piece 2;

[0051] The interior of the shaft sleeve 1 is provided with the dynamic sealing structure near the transmission input end, and the outer surface of the shaft sleeve 1 is provided with an assembly and fixing structure of the shaft sleeve 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com