High Precision Current Transformer

A current transformer, high-precision technology, applied in the field of transformers, can solve the problems of full load overheating, small current value at the measuring end, low measurement accuracy, etc., to achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

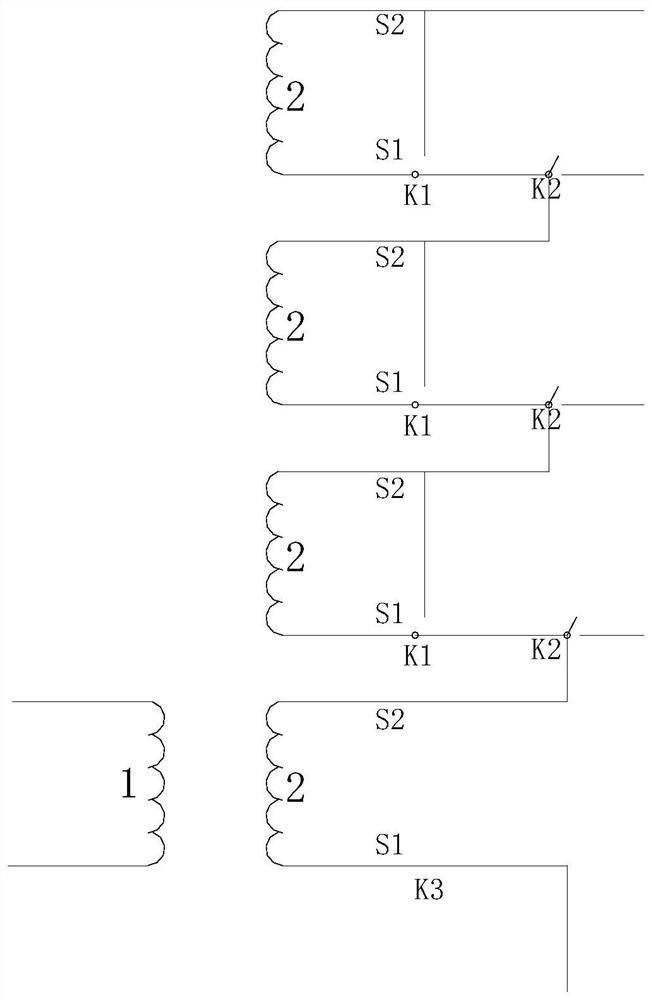

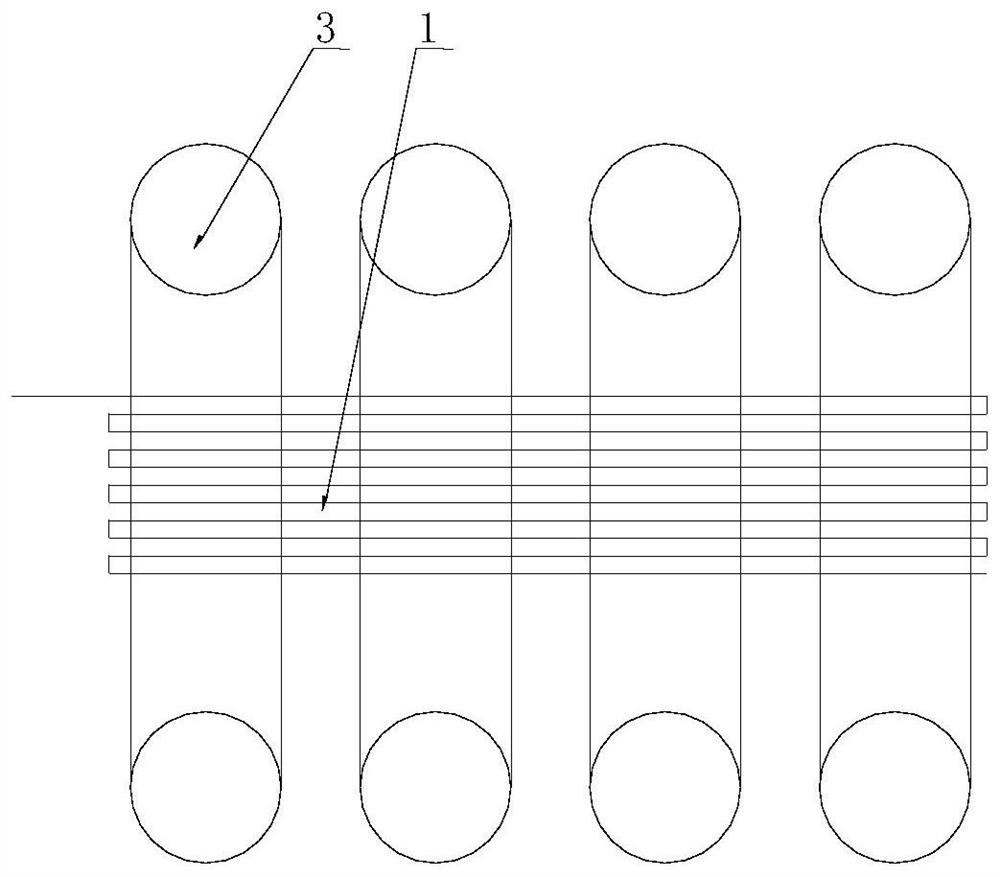

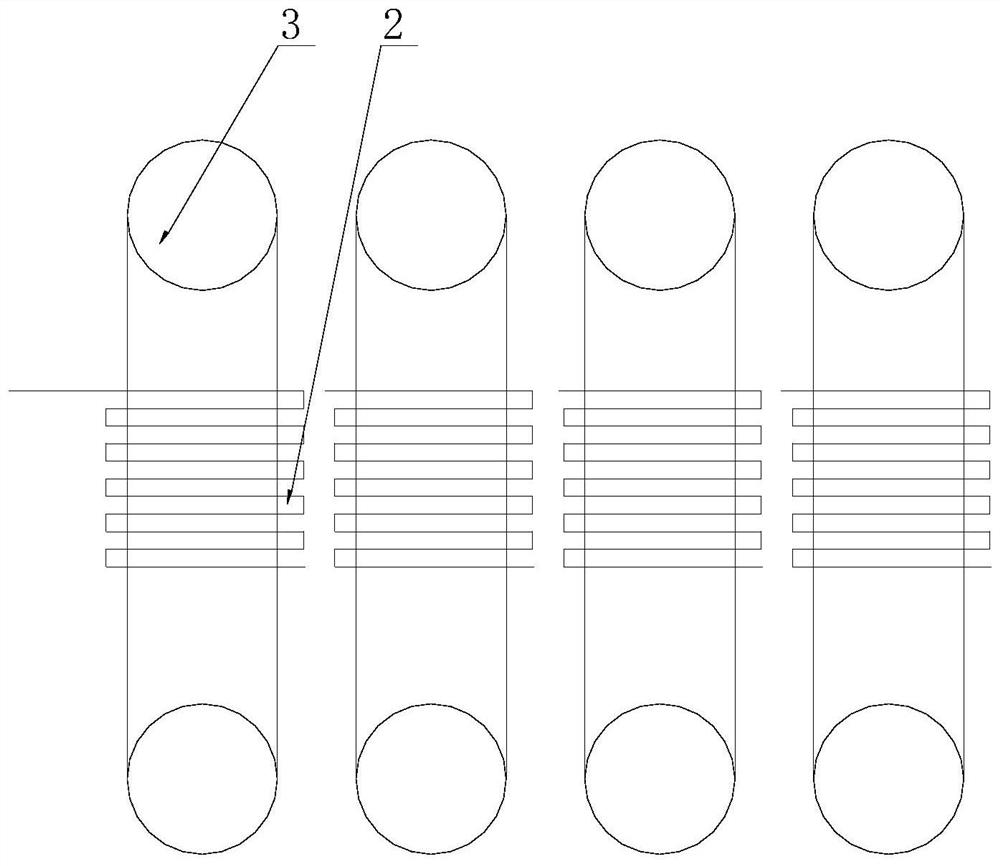

[0032] like Figure 1-6 As shown, the high-precision current transformer includes a primary winding 1 and several secondary windings 2, the primary winding 1 and several secondary windings 2 form several winding units, and each winding unit includes a secondary winding 2, several Two secondary windings 2 are connected in series or disconnected through the disconnect switch K2.

[0033] Several secondary windings 2 are respectively wound on each iron core 3 , the number of iron cores 3 is the same as that of the secondary windings 2 , and the primary winding 1 is wound on several iron cores 3 .

[0034] Each secondary winding 2 is provided with two outlets, namely the first outlet S1 and the second outlet S2;

[0035] The first outgoing terminal S1 of one secondary winding 2 of two adjacent secondary windings 2 and the second outgoing terminal S2 of the other secondary winding 2 are jointly connected to the moving end of the disconnecting switch K2, and the non-conducting term...

Embodiment 2

[0055] like Figure 7 As shown, on the basis of Embodiment 1, a main terminal switch K3 is provided between the first outlet terminal S1 of the first secondary winding 2 of several secondary windings 2 and the secondary winding 2, and the main terminal switch K3 The moving end is connected to the secondary winding 2 , the non-moving end is connected to a short-circuit wire, and the other end of the short-circuit wire is connected to the second outlet S2 of the secondary winding 2 . The main terminal switch K3 short-circuits the secondary winding 2 at the first terminal, so that the entire secondary winding 2 is disconnected from the detection module. As a safety guarantee measure, the high voltage hazard caused by the complete open circuit of the secondary winding 2 is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com