Lane rope float

A technology of lane-dividing lines and floats, which is applied to public buildings, gymnasiums, building types, etc., can solve the problems of low wave-absorbing performance and large gaps between floats used for lane-dividing lines, etc., and achieve high wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

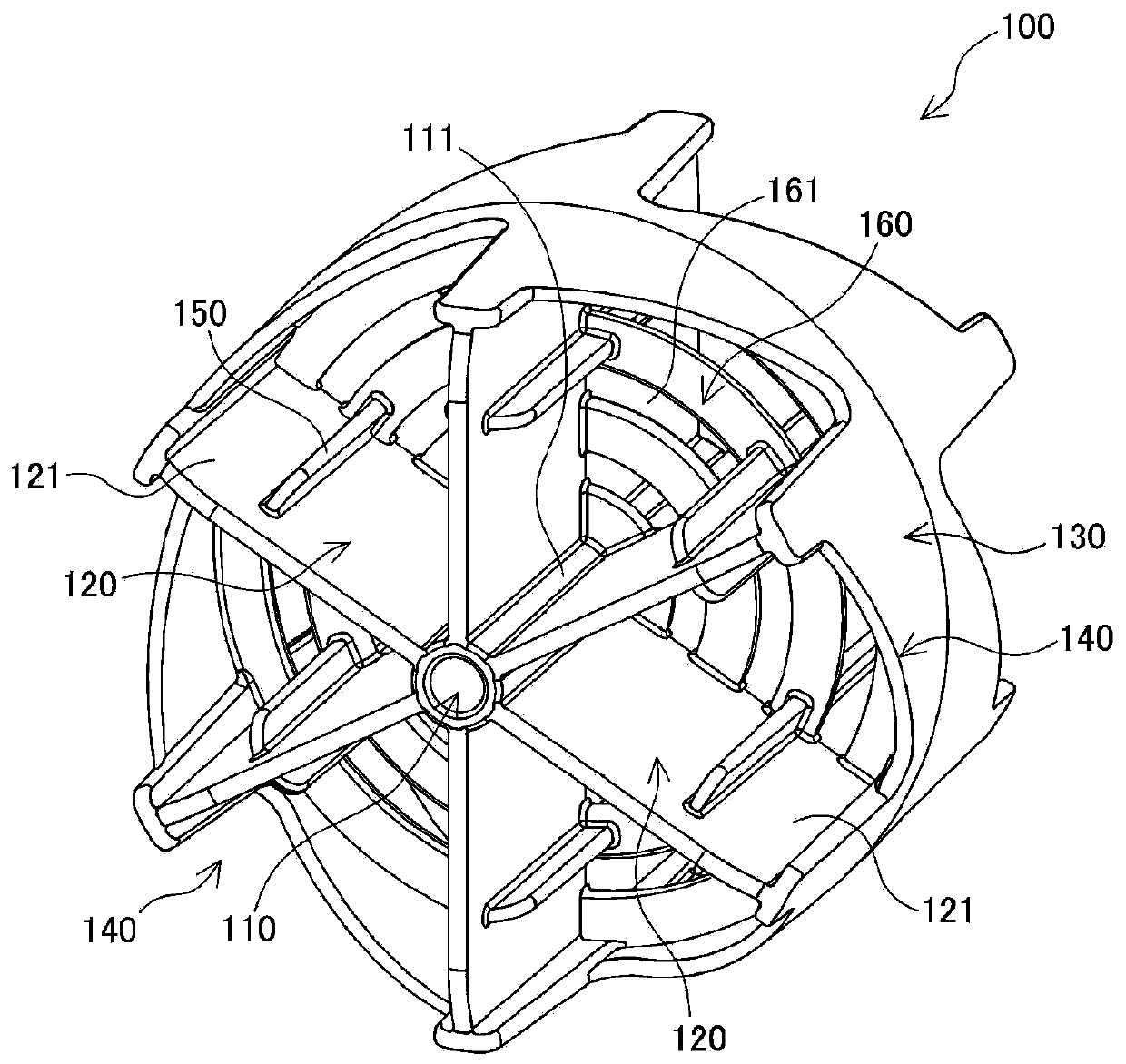

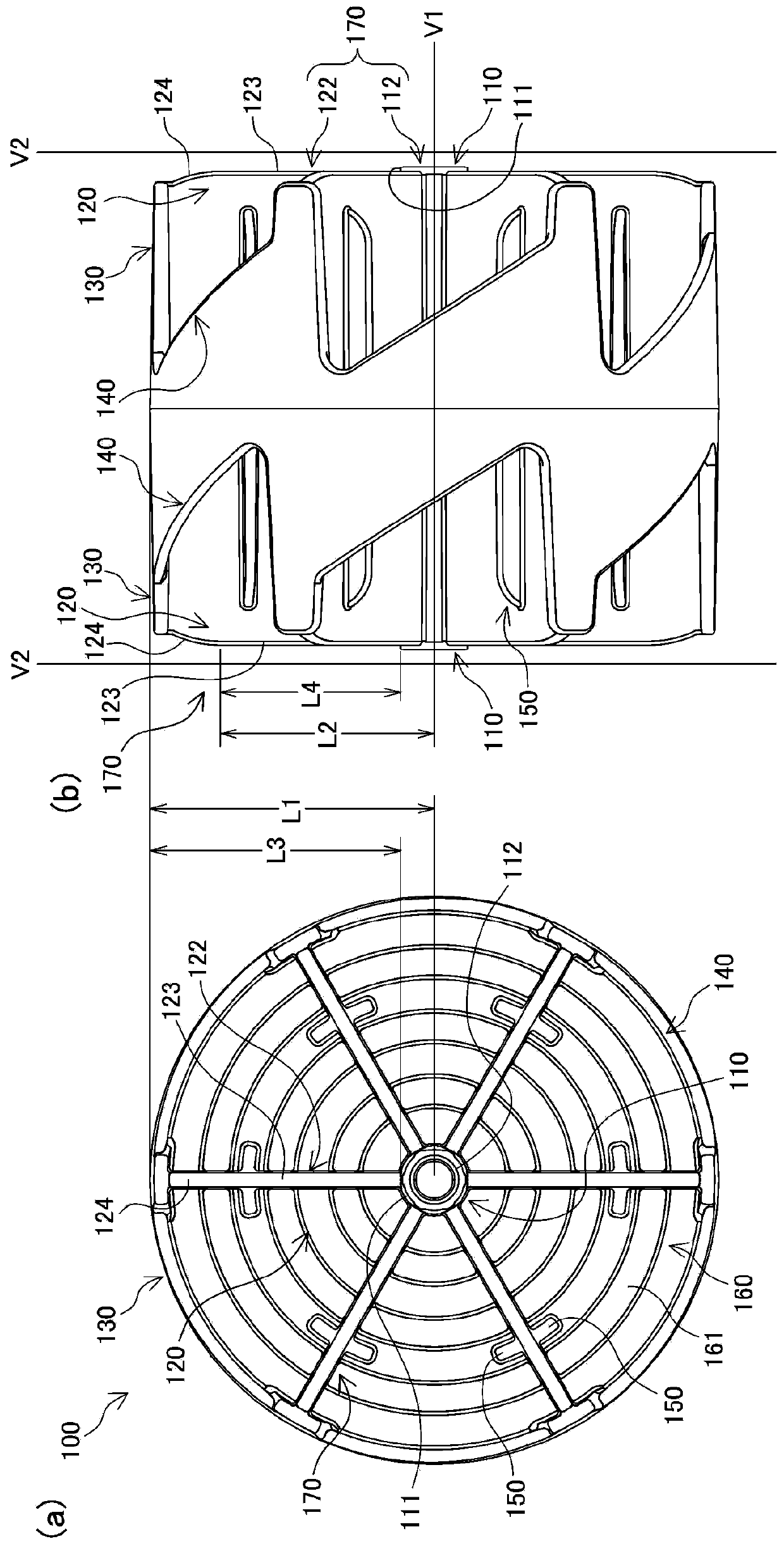

[0051] first, figure 1 with figure 2 The float 100 for lanes according to Embodiment 1 of the present application is shown. figure 1 It is an overall perspective view of the float 100 for the lane dividing line, figure 2 (a) is a front view of the float 100 for the lane line, figure 2 (b) is a side view of the float 100 for lane markings.

[0052] The lane-dividing float 100 has: a long cylindrical portion 110 located at the center of the lane-dividing float 100 through which the rope R can be inserted; The side surface 111 protrudes parallel to the rope R; and the wall surface 130 is connected to the side end 121 of the wing plate 120 and covers the wing plate 120 .

[0053] The wall surface 130 between adjacent blades 120 is formed obliquely. In addition, openings 140 are formed on both sides of the inclined portion, and waves advancing from the side enter into the lane line float 100 through the openings 140 . Furthermore, a protruding plate 150 parallel to the r...

Embodiment approach 2

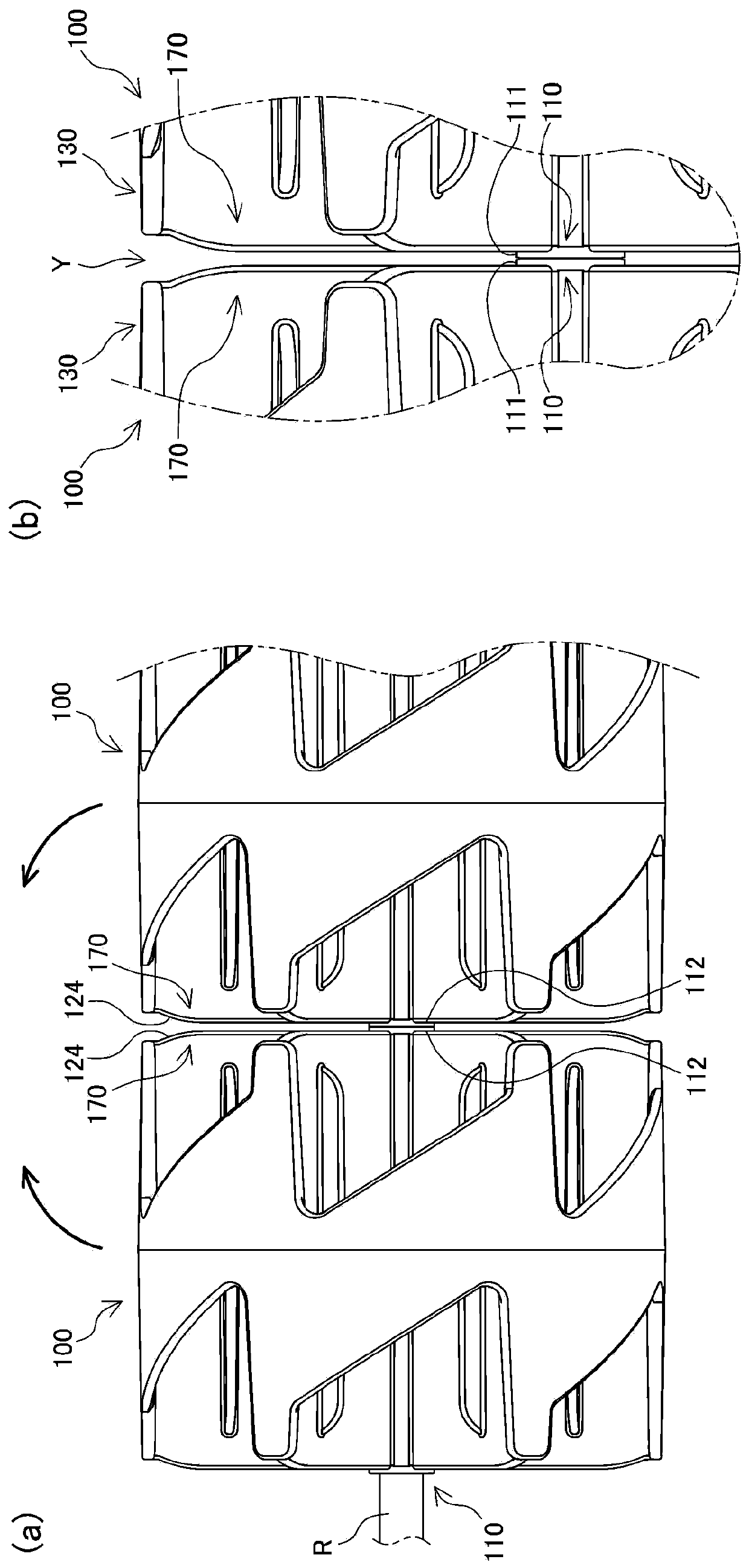

[0103] Next, refer to Figure 7 The lane-dividing float 100D according to Embodiment 2 of the present application will be described. It should be pointed out that Figure 7 (a) is a side view of the lane line float 100D, Figure 7 (b) is a side view of a state in which a plurality of lane-dividing floats 100D are attached to the rope R, Figure 7 (c) is to enlarge Figure 7 (b) is a side view of the vicinity of one outer end 170Da and the other outer end 170Db of the float 100D for lane dividing. In addition, the composition of the float 100D for lane-dividing lines is different from that of the float for lane-dividing lines except that the configuration of the one outer end 170Da and the other outer end 170Db is different from the outer end 170 of the float 100 for lane-dividing lines. 100 has the same configuration, so detailed description thereof will be omitted.

[0104] Such as Figure 7 As shown in (a), in one outer end portion 170Da of the float 100D for a lane li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com