An automatic jet-flow floating breakwater and its wave-absorbing method

A floating breakwater, automatic technology, applied in the direction of breakwaters, embankments, jetties, etc., can solve the problem of wasting money, save energy, enhance wave absorption performance, and meet the requirements of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

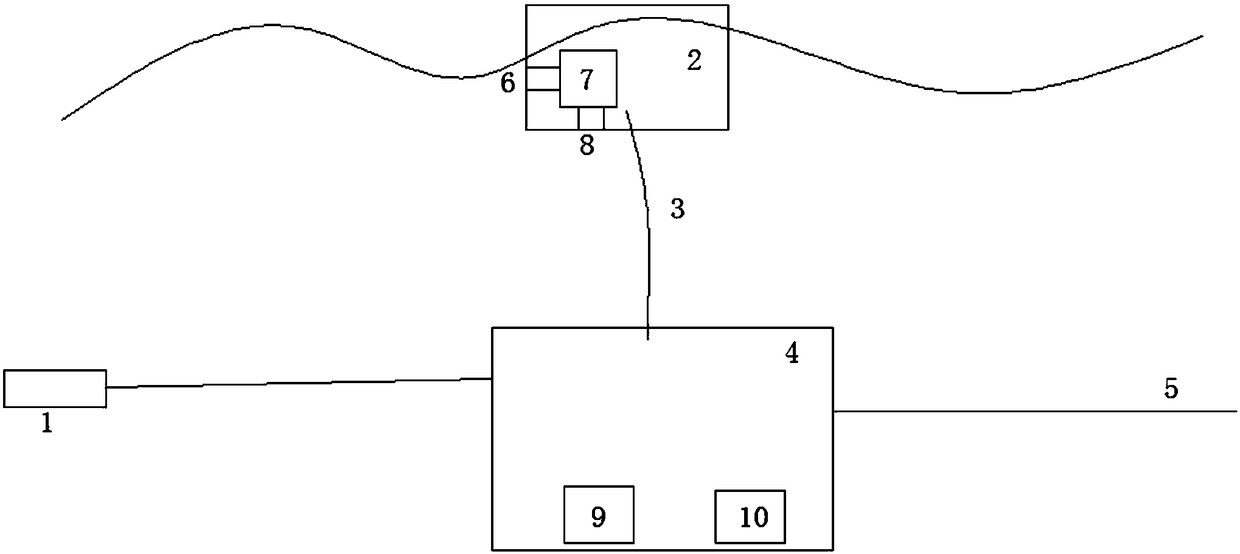

[0023] Example 1, such as figure 1 As shown, this embodiment discloses a new type of automatic jet floating breakwater, which includes a base 4 that sinks into the bottom of the water and a floating body 2 floating on the water surface. The base and the floating body are connected by anchor chains 3. Water pump 7, the water inlet 8 of this water pump is arranged on the lower part of the floating body, and the water outlet 6 is arranged on the facing wave side of the floating body; a single-chip microcomputer 9 is installed in the base, and a pressure wave height meter 1 is arranged in front of the facing wave side of the base. The wave height meter is electrically connected with the water pump, and the switch and flow of the water pump are controlled according to the data from the pressure type wave height meter. The single-chip microcomputer is electrically connected with the water pump switch 10 installed in the base, and controls the switch and flow of the water pump throug...

Embodiment 2

[0029] Embodiment 2. This embodiment discloses another new type of automatic jet floating breakwater, which includes a base that sinks into the bottom of the water and a floating body that floats on the water surface. The base and the floating body are connected by anchor chains, and a water pump is arranged in the floating body. , the water inlet of the water pump is set on the lower part of the buoyant body, and the water outlet is set on the facing wave side of the buoyant body; the bottom of the buoyant body is also provided with a waterproof box, and a single-chip microcomputer is installed in the waterproof box, and the probe of the pressure wave height meter is set on the outside of the waterproof box. On the wave side, the single-chip microcomputer is electrically connected with the pressure wave height meter and the water pump, and controls the switch and flow of the water pump according to the data from the pressure wave height meter. The single chip microcomputer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com