Building concrete preparation equipment and its working method

A technology of concrete and concrete mortar, applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

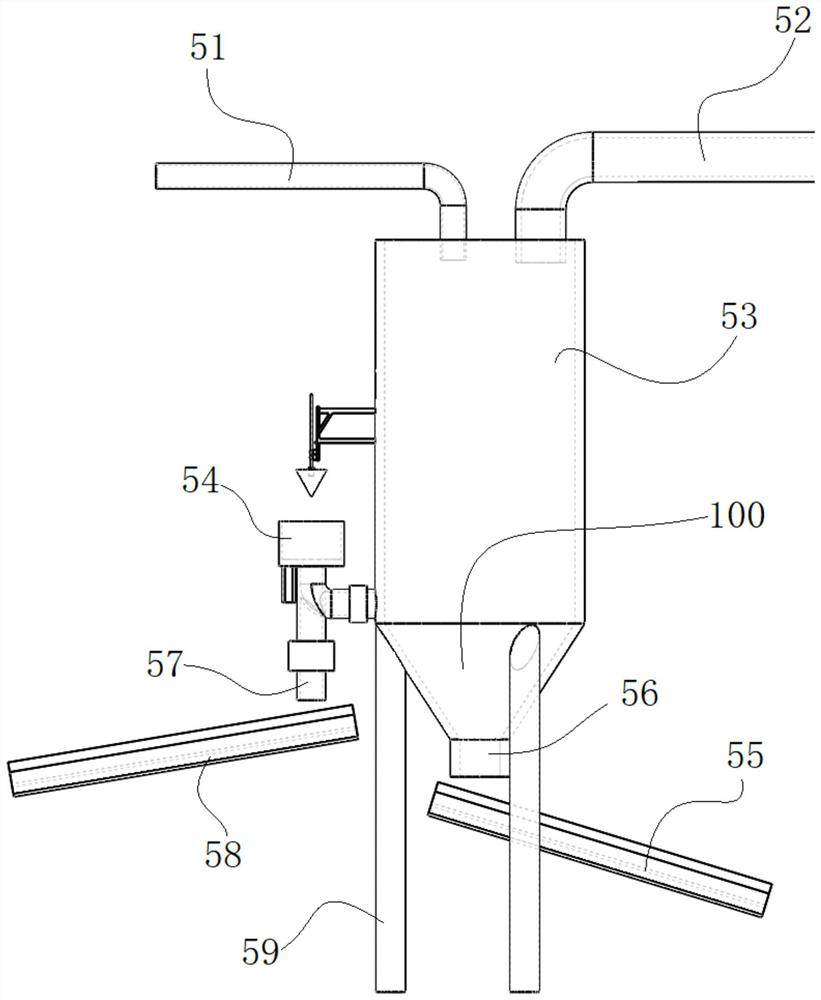

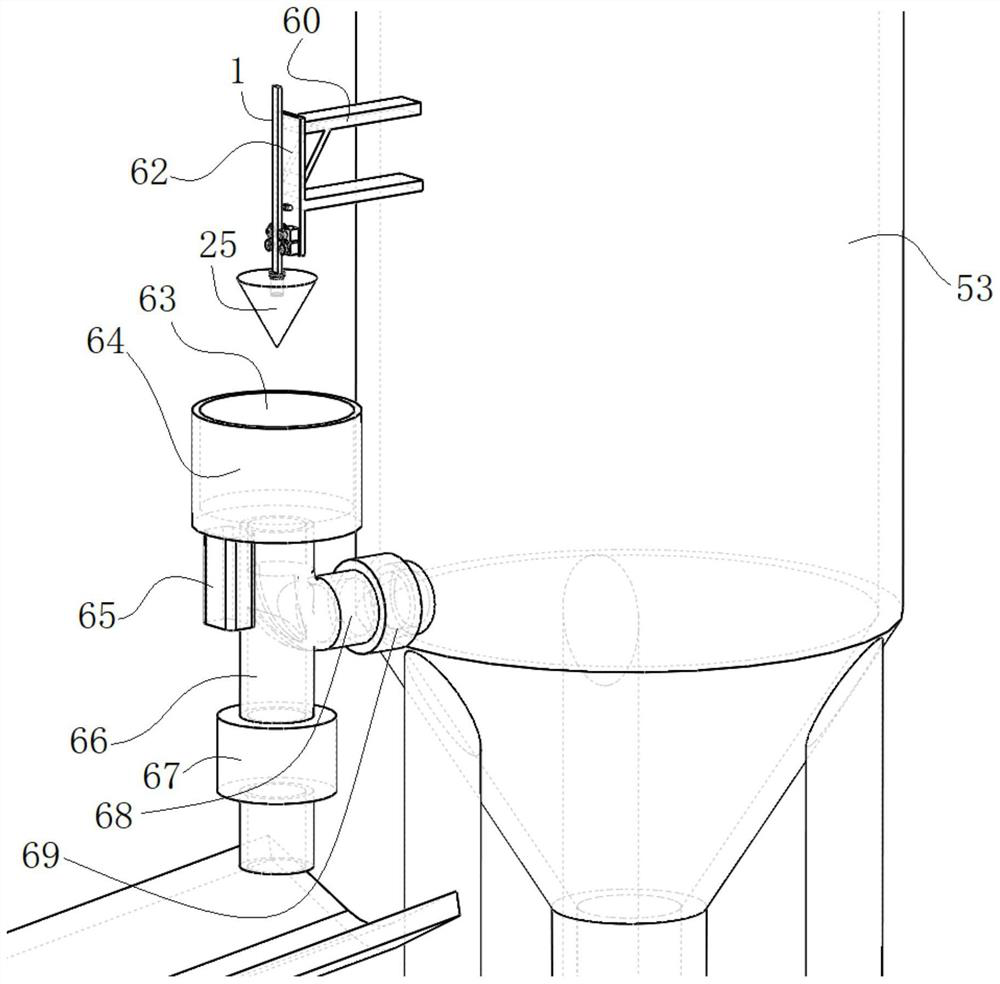

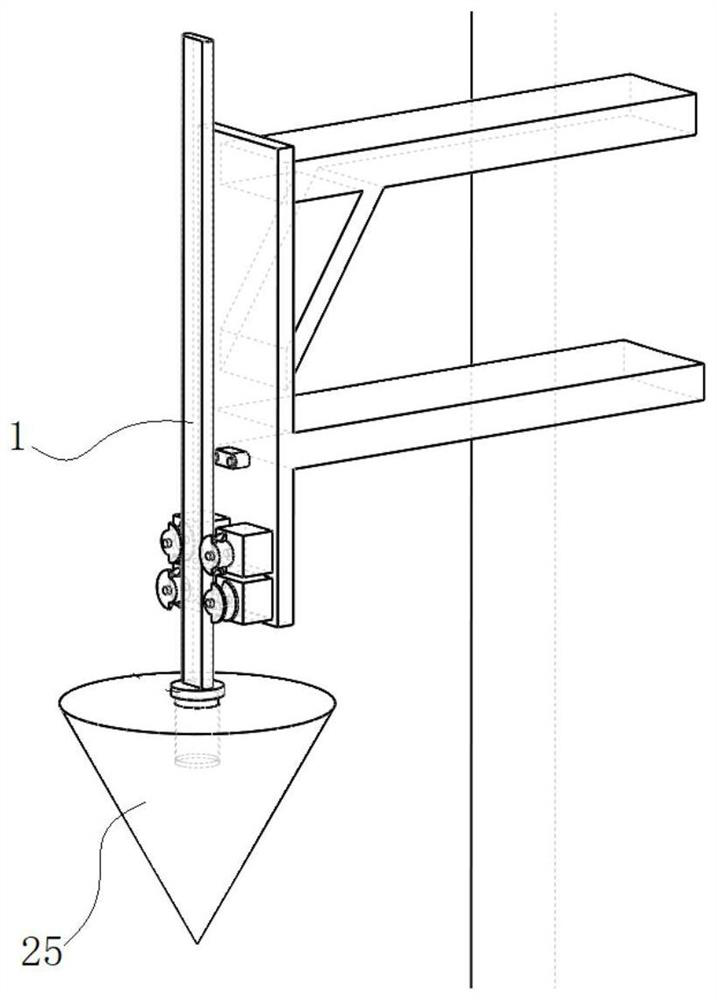

[0033] as attached Figures 1 to 11 Construction concrete preparation equipment includes a concrete mortar mixing tower 53, the inside of the concrete mortar mixing tower 53 is provided with a stirring device, the mortar mixing tower 53 is vertically supported by several supports 59, and the concrete mortar mixing tower 53 The bottom end is a tapered lower hopper 100 with the tip pointing down; the lower end of the tapered lower hopper 100 is provided with a discharge port 56, and a valve is provided in the discharge port 56; it also includes The first material guide trough 55 arranged obliquely; the bottom of the discharge port 56 corresponds to the high end of the first material guide trough 55; it also includes a concrete batching delivery pipe 52 and a water supply pipe 51; the concrete batching delivery pipe 52 Both the water supply pipe 51 and the discharge end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com