Construction method of hydrophobic structure of water delivery culvert pipe joint expansion joint

A construction method and technology of expansion joints, which are applied in water conservancy projects, hydroelectric power generation, hydropower stations, etc., can solve the problems of expansion joint water-stop packing damage, water leakage in pipes, and other problems that cannot be completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

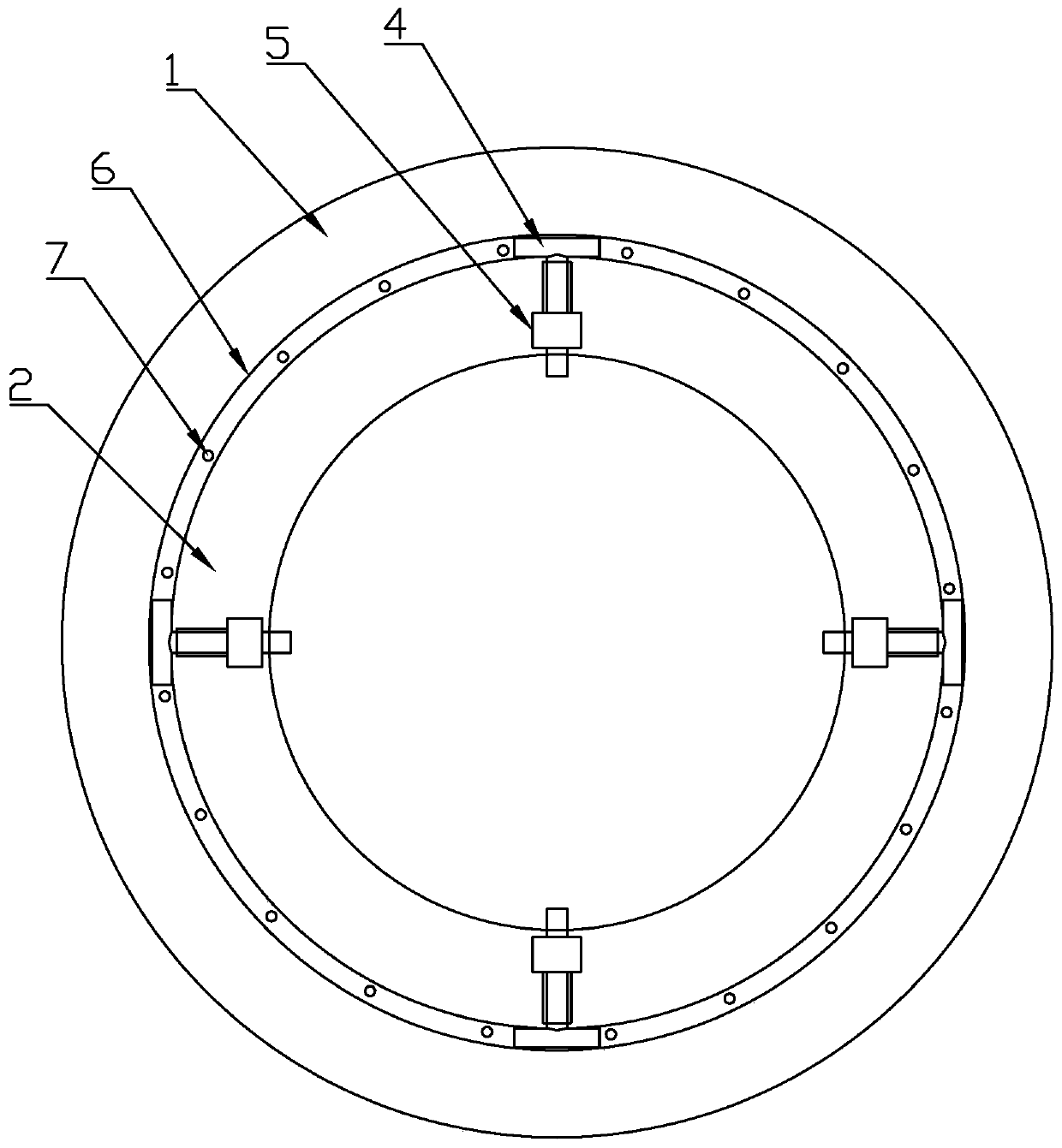

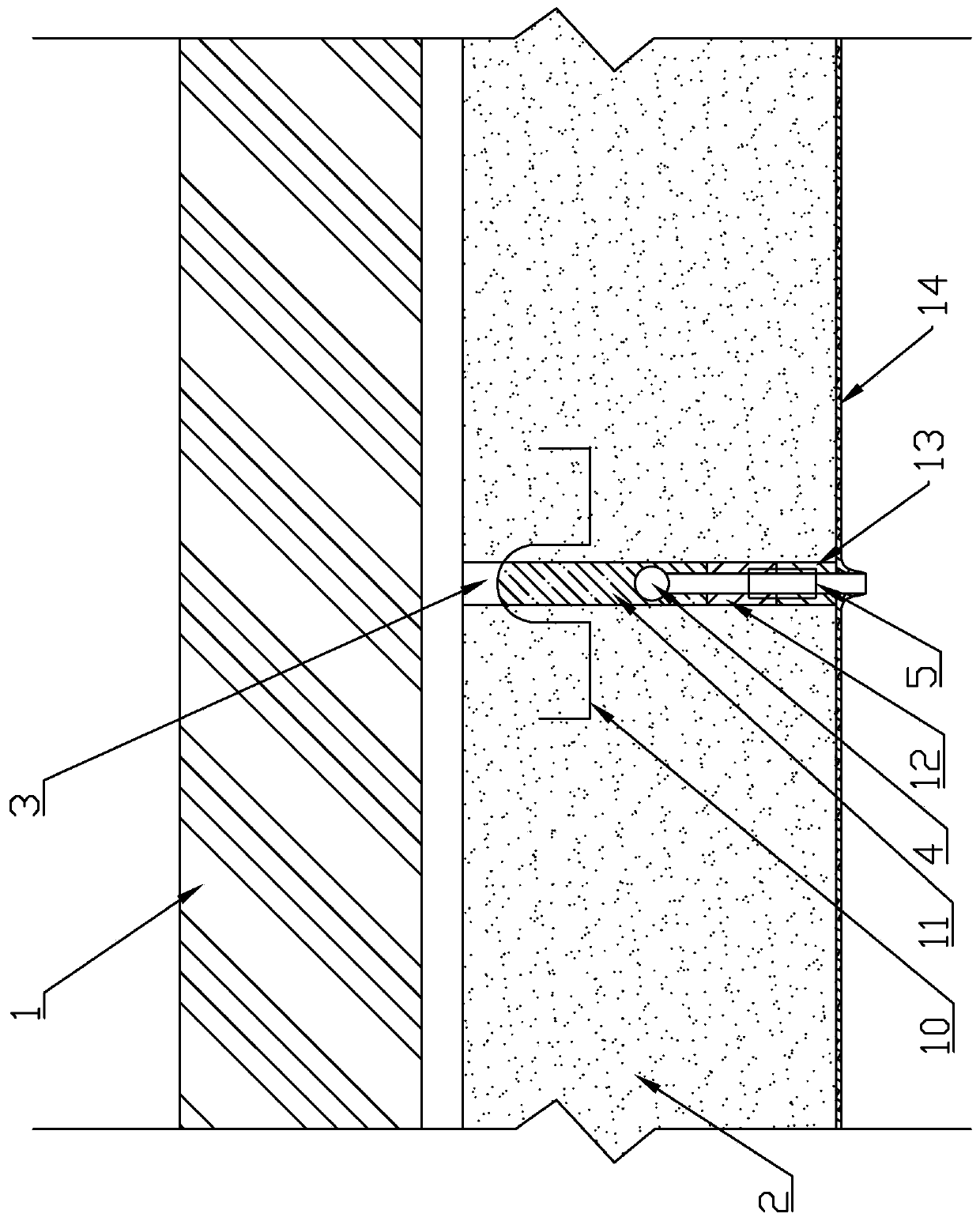

[0025] Such as figure 1 , figure 2 As shown, the hydrophobic structure of the expansion joint of the pipe joint of the water delivery culvert provided by the present invention, the water delivery culvert has a tubular reinforced concrete lining 1 arranged on the outer peripheral side, which is used to bear the earthwork pressure; A tubular reinforced concrete second lining 2 connected head to tail (i.e. the aforementioned pipe joint) is used for water delivery; expansion joints 3 are formed at the joint positions of the reinforced concrete second lining 2 (such as image 3 shown);

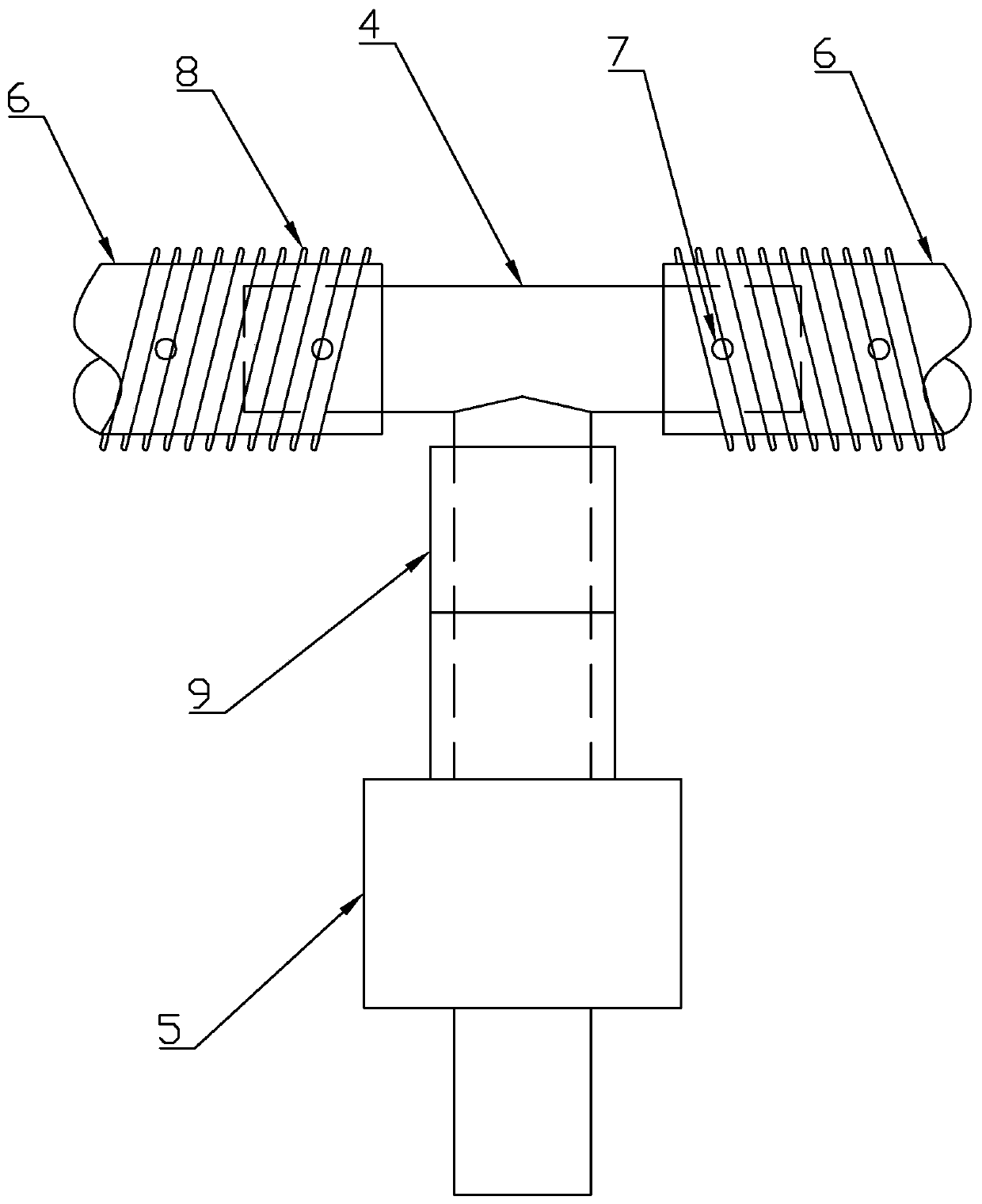

[0026] At least fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com