A Throat Offset Pneumatic Vectoring Nozzle with Internal S-Bend

A vector nozzle and throat technology, applied in the field of advanced thrust vector nozzles, can solve the problems of complex structure, troublesome maintenance, poor reliability, etc., and achieve the effect of widening the working envelope, good applicability, and reducing the reflection cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

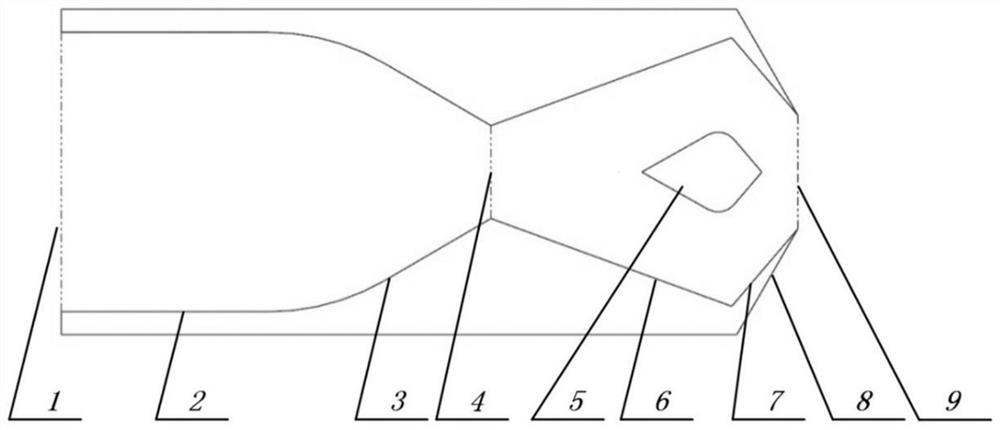

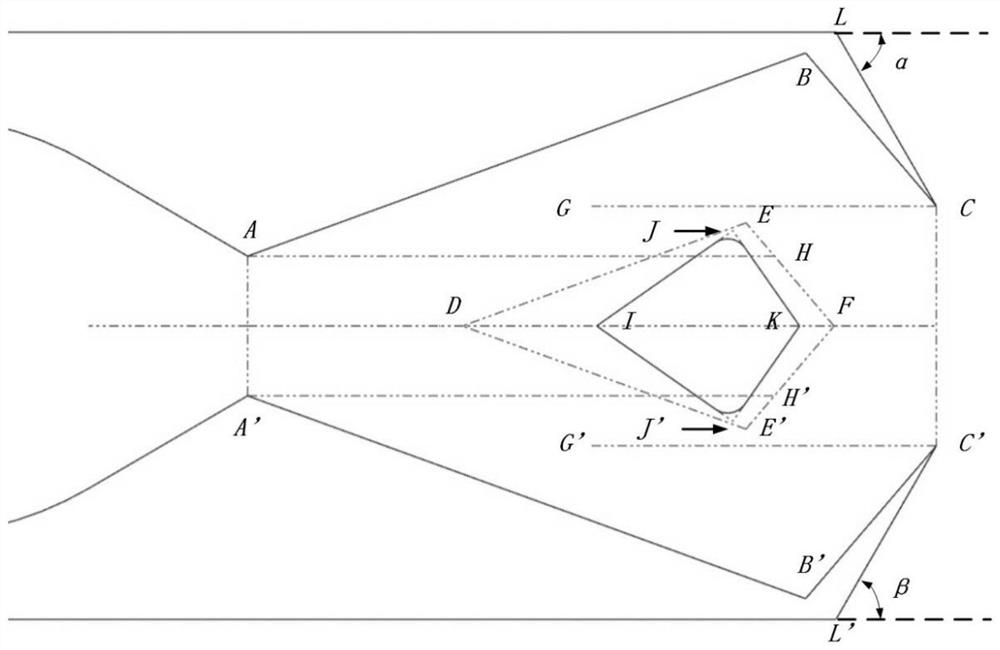

Image

Examples

Embodiment

[0048] The calculation is carried out for the typical configuration of the throat offset aerodynamic vectoring nozzle with inner S-bend and its control method.

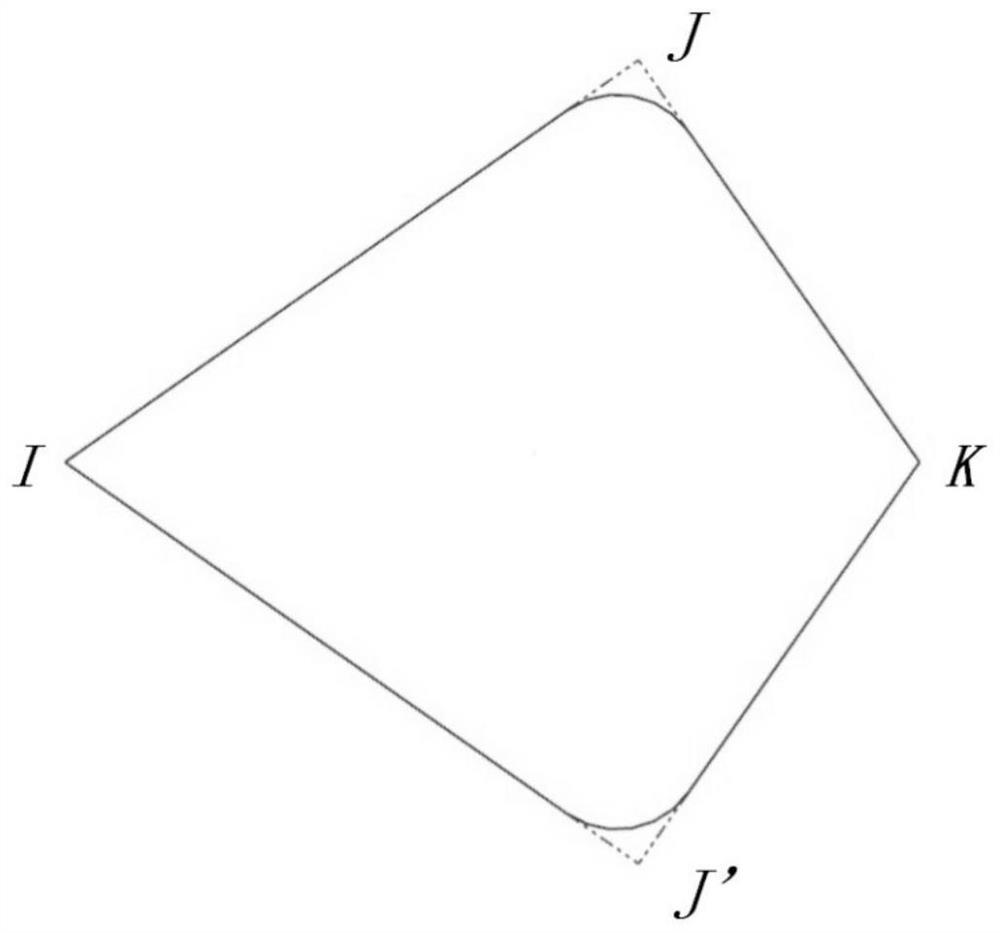

[0049] Figure 5 show is Figure 4 The performance curves of the thrust vector angle of the three nozzle configurations as a function of the working drop pressure ratio. where curve A corresponds to Figure 4 The central cone configuration of the solid line in the curve B corresponds to Figure 4 The dotted line in the central cone configuration, curve C corresponds to Figure 4 Nozzle configuration without central cone.

[0050] It can be seen that the central cone of the solid line and the central cone of the dotted line are quite different in the shape of the head, and its influence on the performance of the nozzle is also obvious. The thrust vector angle performance of the dotted center cone is the worst. After optimizing the profile of the nozzle head, the thrust vector angle performance has been significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com