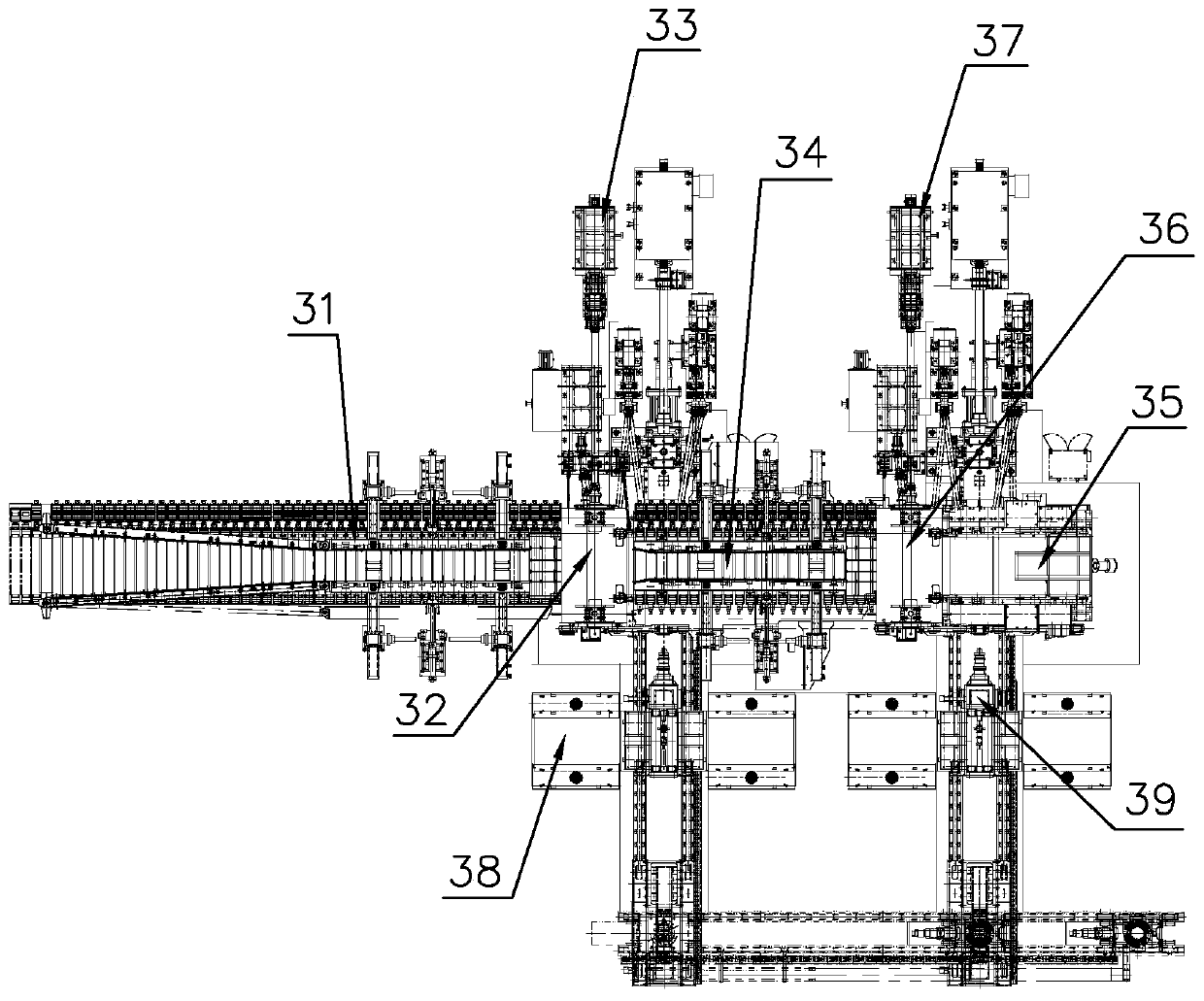

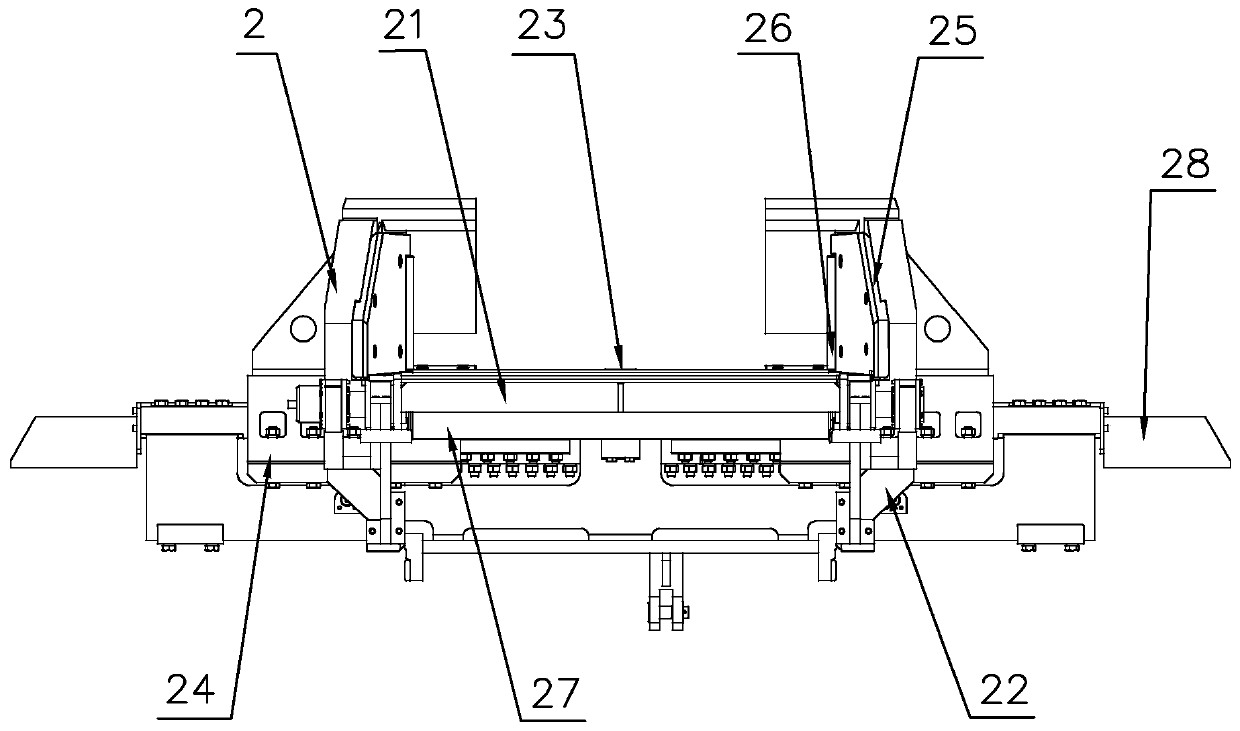

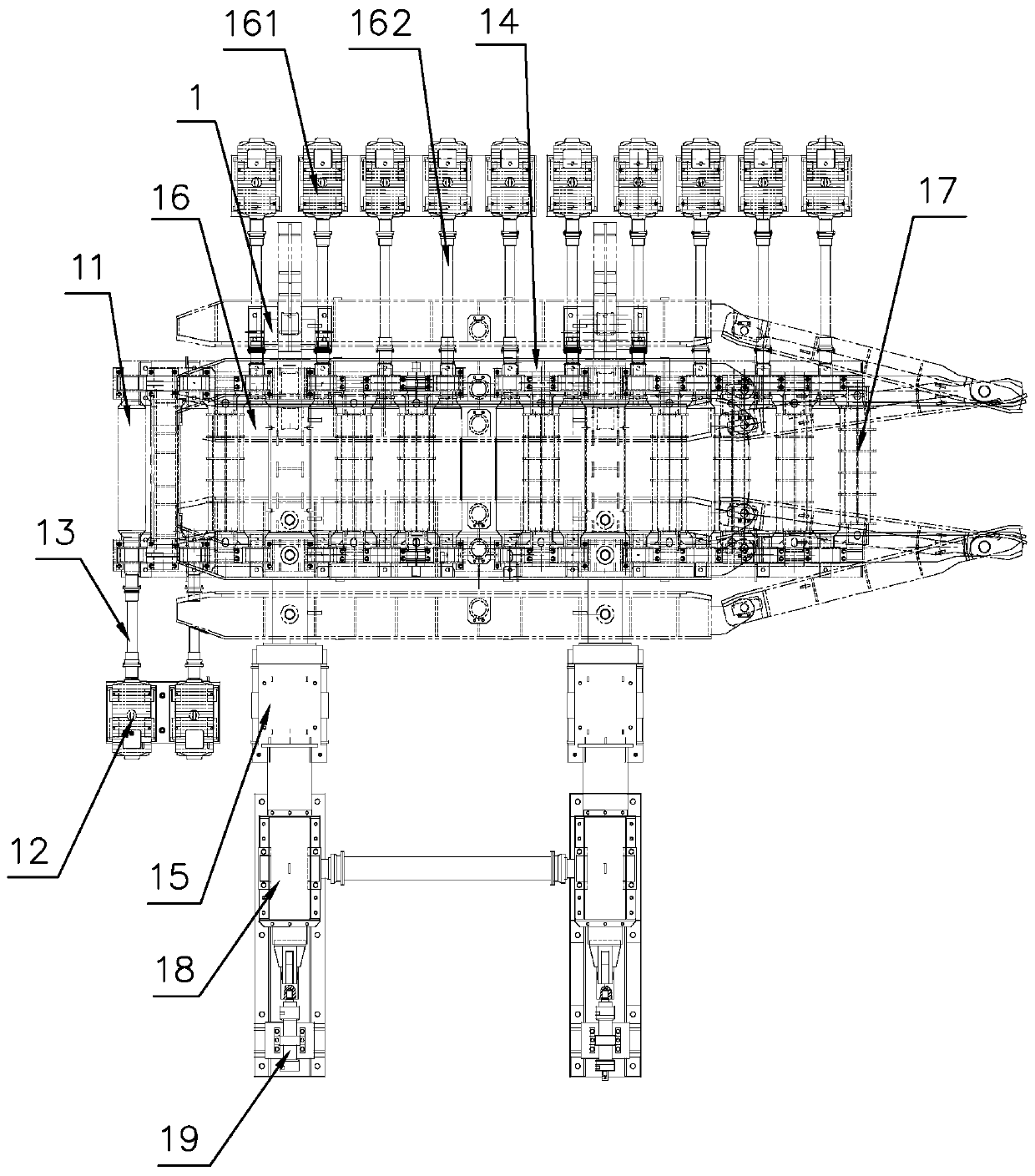

Wide-band thin stainless steel rolling equipment and wide-band thin stainless steel hot rolling process

A technology of stainless steel and strip steel, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as impact, punching out of wires, and affecting the quality of wide-band thin plate stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: a kind of broadband thin plate stainless steel hot rolling process:

[0050] 1) Rough rolling preparation, before the strip steel enters the side guide plate during the rough rolling process, the opening of the side guide plate is set to be 40mm wider than the strip steel;

[0051] 2) Strip centering, after the strip enters the side guide plate, the roller shaft stops running, and the side guide plate is synchronously and symmetrically moved closer to the rolling center line so that the side guide plate moves closer to center the strip steel;

[0052] 3) Carry out rough rolling, when the centering of the strip is completed, the side guide plate is quickly opened to a distance of 40mm, and the strip begins to run to the rolling mill to complete the rough rolling process;

[0053] 4) After the rough rolling is completed, after the strip passes through, the side guide plates are synchronized and the center line of the rolling is opened symmetrically, ready fo...

Embodiment 2

[0063] Embodiment 2: a kind of broadband thin plate stainless steel hot rolling process:

[0064] 1) Rough rolling preparation, before the strip steel enters the side guide plate during the rough rolling process, the opening of the side guide plate is set to be 50mm wider than the strip steel;

[0065] 2) Strip centering, after the strip enters the side guide plate, the roller shaft stops running, and the side guide plate is synchronously and symmetrically moved closer to the rolling center line so that the side guide plate moves closer to center the strip steel;

[0066] 3) Carry out rough rolling, when the centering of the strip is completed, the side guide plate is quickly opened to a distance of 50mm, and the strip begins to run to the rolling mill to complete the rough rolling process;

[0067] 4) After the rough rolling is completed, after the strip passes through, the side guide plates are synchronized and the center line of the rolling is opened symmetrically, ready fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap