Triangular crawler wheel driving wheel driving structure

A technology of triangular crawler and driving structure, which is applied in the directions of crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of high vehicle height and low driving efficiency of driving wheels, and can reduce the height of the vehicle and improve the wheel side drive. Efficiency, the effect of reducing the vertical distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

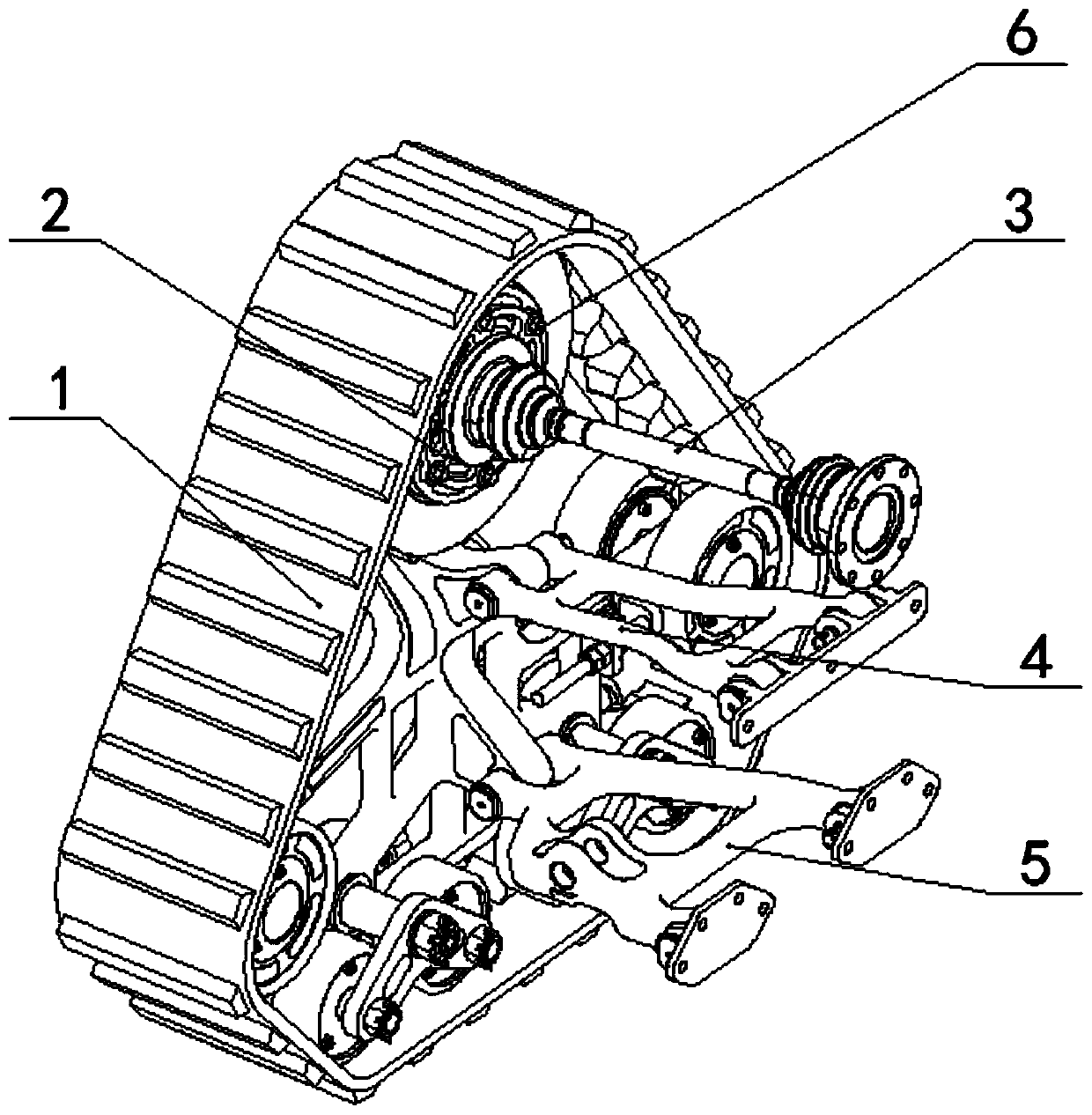

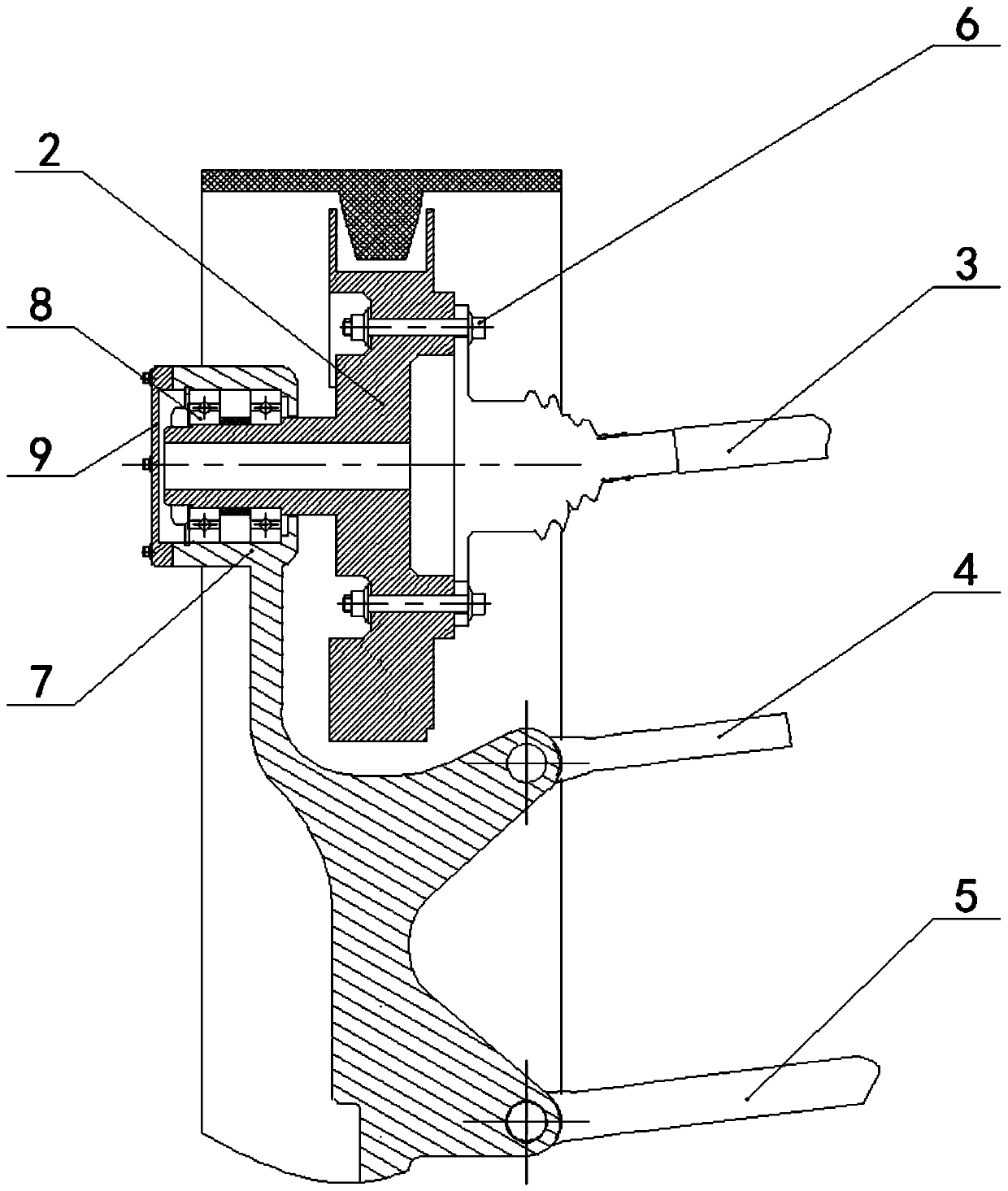

[0011] A driving structure of a triangular track wheel driving wheel involved in this embodiment, its structure is as follows figure 1 As shown, the cross-sectional view is as figure 2 shown. The structure includes a triangular track wheel 1, a driving wheel 2, a wheel drive shaft 3, an upper swing arm 4, a lower swing arm 5, a connecting bolt 6, a frame with a bearing chamber 7, a rolling bearing 8, and a bearing end cover 9. Among them: the driving wheel 2 contained in the triangular track wheel 1 is connected with the wheel drive shaft 3 through the connecting bolt 6; The band bearing chamber skeleton 7 is connected, and the bearing chamber outside is locked with the bearing end cover 9.

[0012] The wheel drive shaft is directly connected with the driving wheel to effectively improve the drive efficiency of the wheel. The upper and lower swing arms are directly connected to the frame with bearing chamber, which greatly reduces the height of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com