Self-cleaning full-automatic vacuum fryer

A vacuum fryer, fully automatic technology, applied in the direction of oil/fat baking, etc., can solve the problems of rising acid value, labor-intensive, easy accumulation of residues at the bottom of the pot, etc., to achieve simple structure, ensure cleanliness, improve frying The effect of manufacturing effect and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

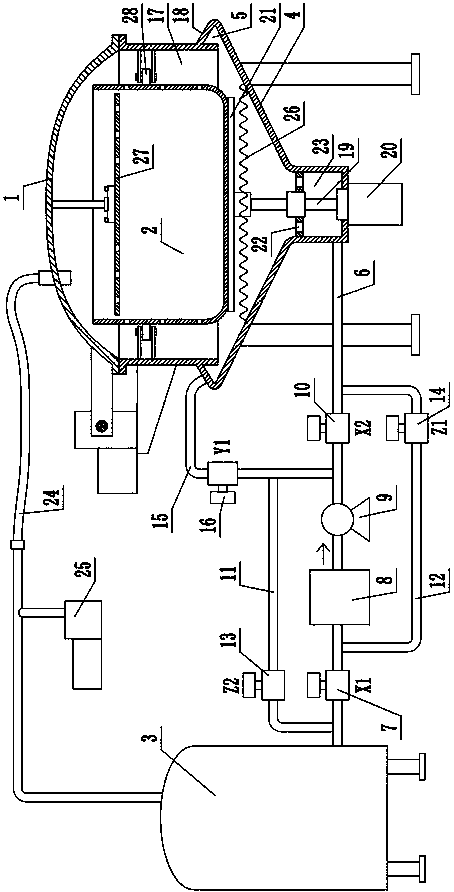

[0021] Referring to the accompanying drawings, the self-cleaning full-automatic vacuum fryer includes a fryer, preferably a pot cover 1 hinged on the top of the fryer, a frying basket 2 that can be placed in the fryer, and an oil storage that can store and heat the oil body. Pot 3; Wherein, the bottom of this fried pot is preferably conical pot bottom section 4, secondly, in order to carry out automatic cleaning to the inner wall of pot bottom section 4, the inner peripheral wall of fryer is provided with a circle of oil spray channel 5, and The fuel injection channel 5 is annularly provided with a circle of fuel injection slots for scouring the inner wall of the bottom section 4 of the pot; figure 1 As shown, in order to realize the structure of the oil injection channel 5 and the oil injection slot, the fryer preferably includes a cylindrical pot body section 17 at the upper end and a pot bottom section 4 at the lower end. In addition, the upper end of the bottom section 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com