Method and apparatus for determining the phase compositions of a multiphase fluid flow

A multi-phase fluid and fluid technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze fluids, liquid/fluid solid measurements, etc., can solve problems such as complex devices and time-consuming processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

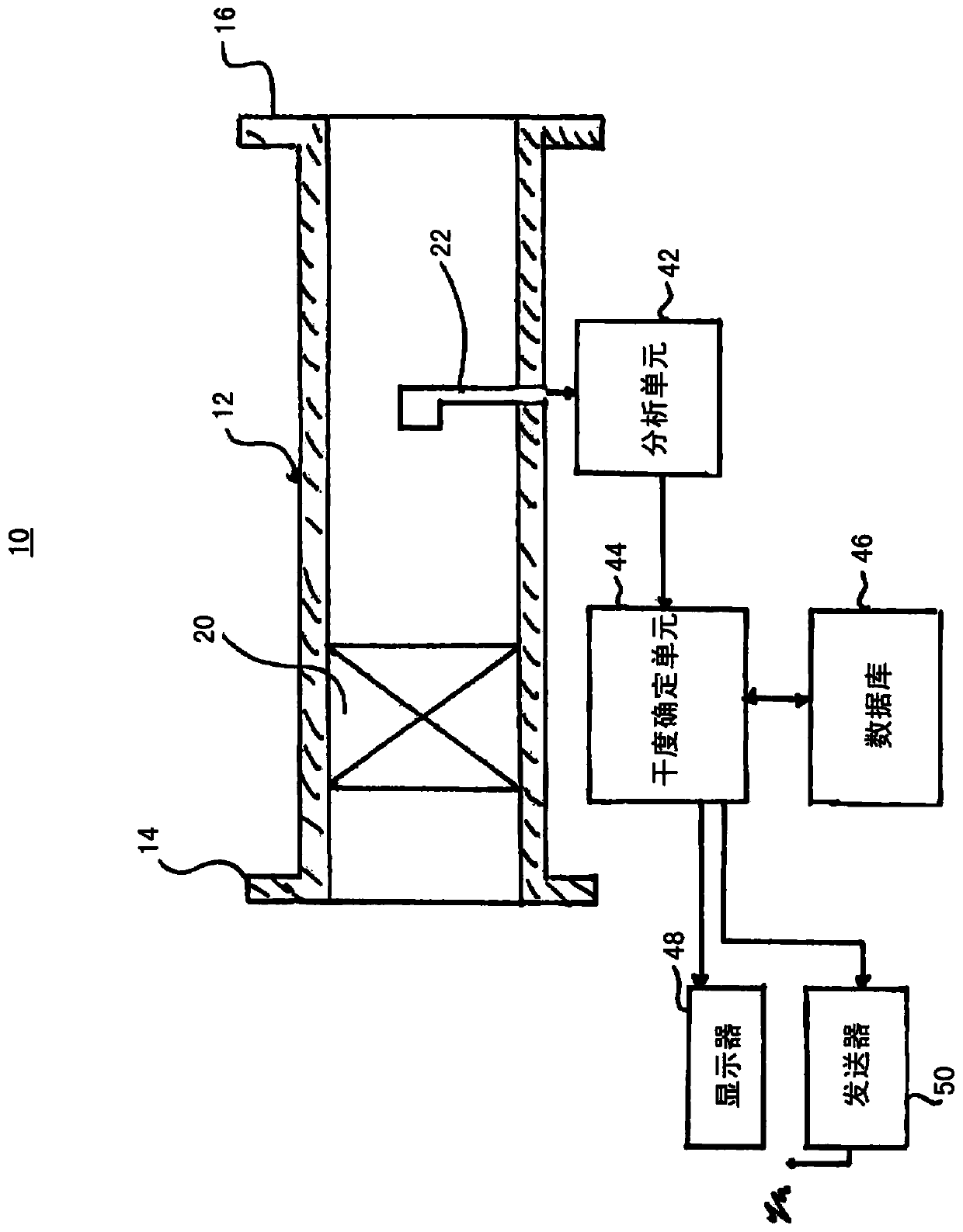

[0037] figure 1 Generally shown is an apparatus 10 for determining the phase composition of wet steam flowing in a steam line. In this particular embodiment, the device 10 is arranged to determine the dryness of the wet steam. Apparatus 10 includes a length of pipe 12 having connecting flanges 14 and 16 at both ends. The device 10 further comprises a vibration sensor 22 for acquiring vibration signals from the steam flow and an upstream fluid agitator 20 for agitating the steam flow.

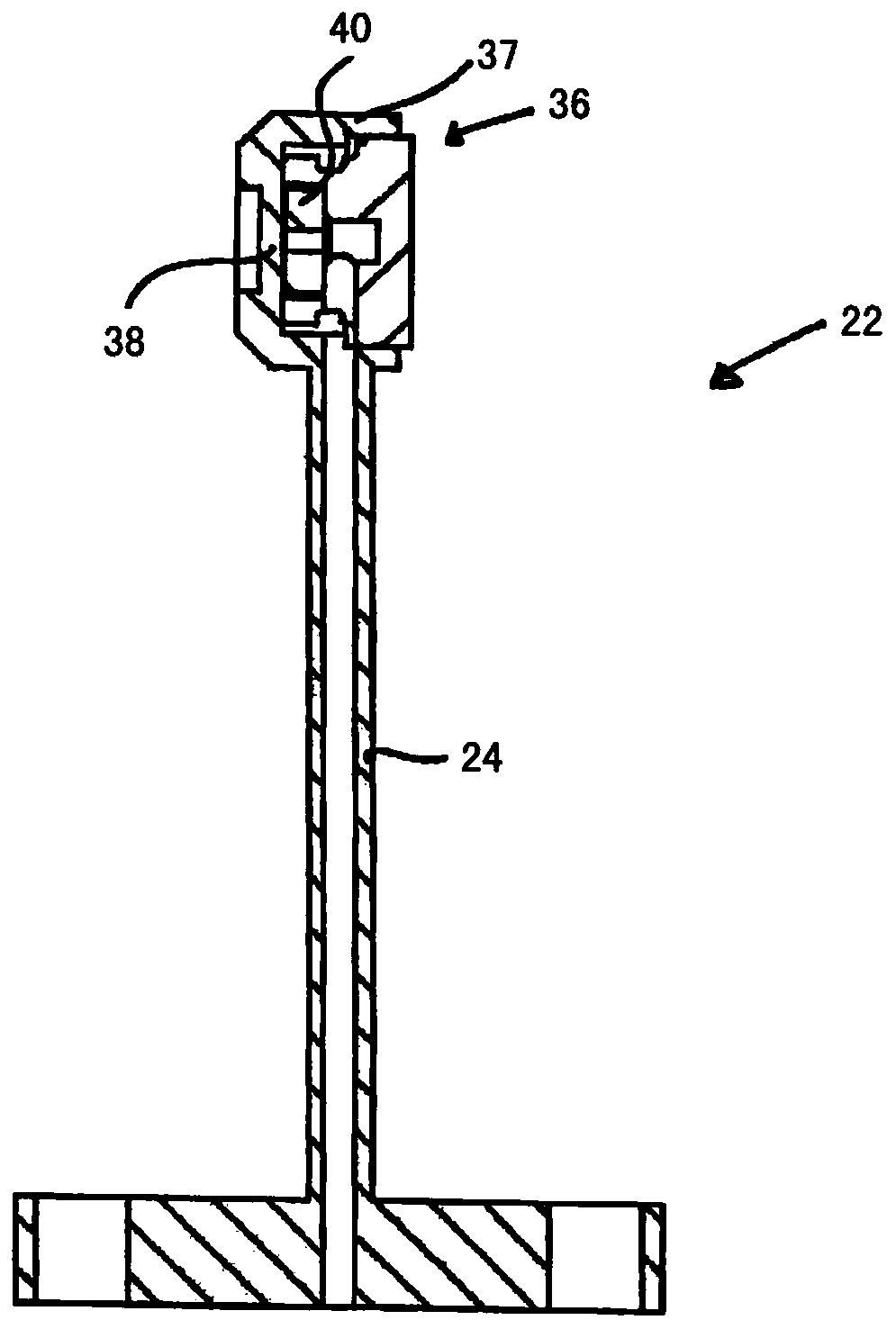

[0038]The vibration sensor 22 is arranged in the pipe 12, downstream of the agitator 20 along the longitudinal direction of the pipe 12 and at the figure 2 shown in more detail. The vibration sensor 22 includes a hollow rod 34 extending into the pipe and a head 36 mounted to the end of the rod 34 and aligned with the axis of the pipe. The head 36 includes a body 37 and a substantially planar target 38 in the form of a diaphragm. The target 38 faces the vapor flow and lies in a plane perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com