A Calculation Method of Bloom Rolling Temperature Field Considering Non-uniform Deformation Heat

A technology of rolling temperature and calculation method, which is applied in the field of iron and steel metallurgy, can solve problems such as large amount of calculation, no consideration of the influence of uneven deformation heat, uneven distribution of deformation heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

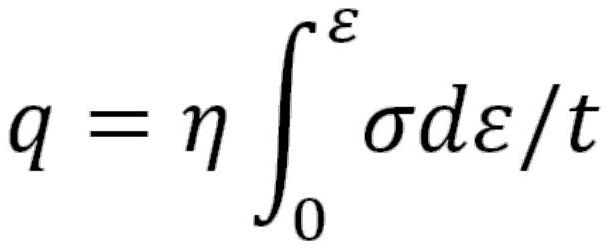

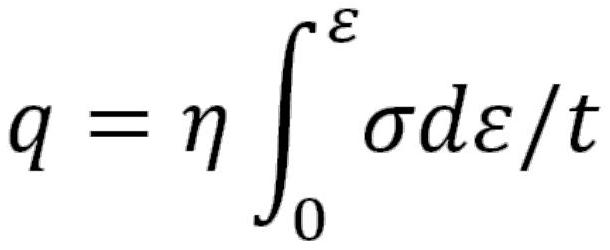

[0030] The invention provides a method for calculating the temperature field of bloom rolling in consideration of uneven deformation heat.

[0031] The method includes steps as follows:

[0032] S1: Using the three-dimensional structural finite element method to establish a single-pass rolling calculation model for blooms:

[0033] S11: Establishing a three-dimensional geometric model of the single-pass rolling of the bloom according to the geometric dimensions of the rolled piece and the roll;

[0034] S12: Divide the geometric model established in S11 into units, first select the unit type, among which, select the 8-node hexahedron unit for the rolled piece, and select the quadrilateral shell unit for the roll, and then determine the grid division for each edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com