Heavy fixture suitable for transfer of cylindrical thin shell and application method thereof

A cylindrical and fixture technology, applied in the field of hoisting fixtures, can solve the problems of inability to use cranes and cranes, and inability to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

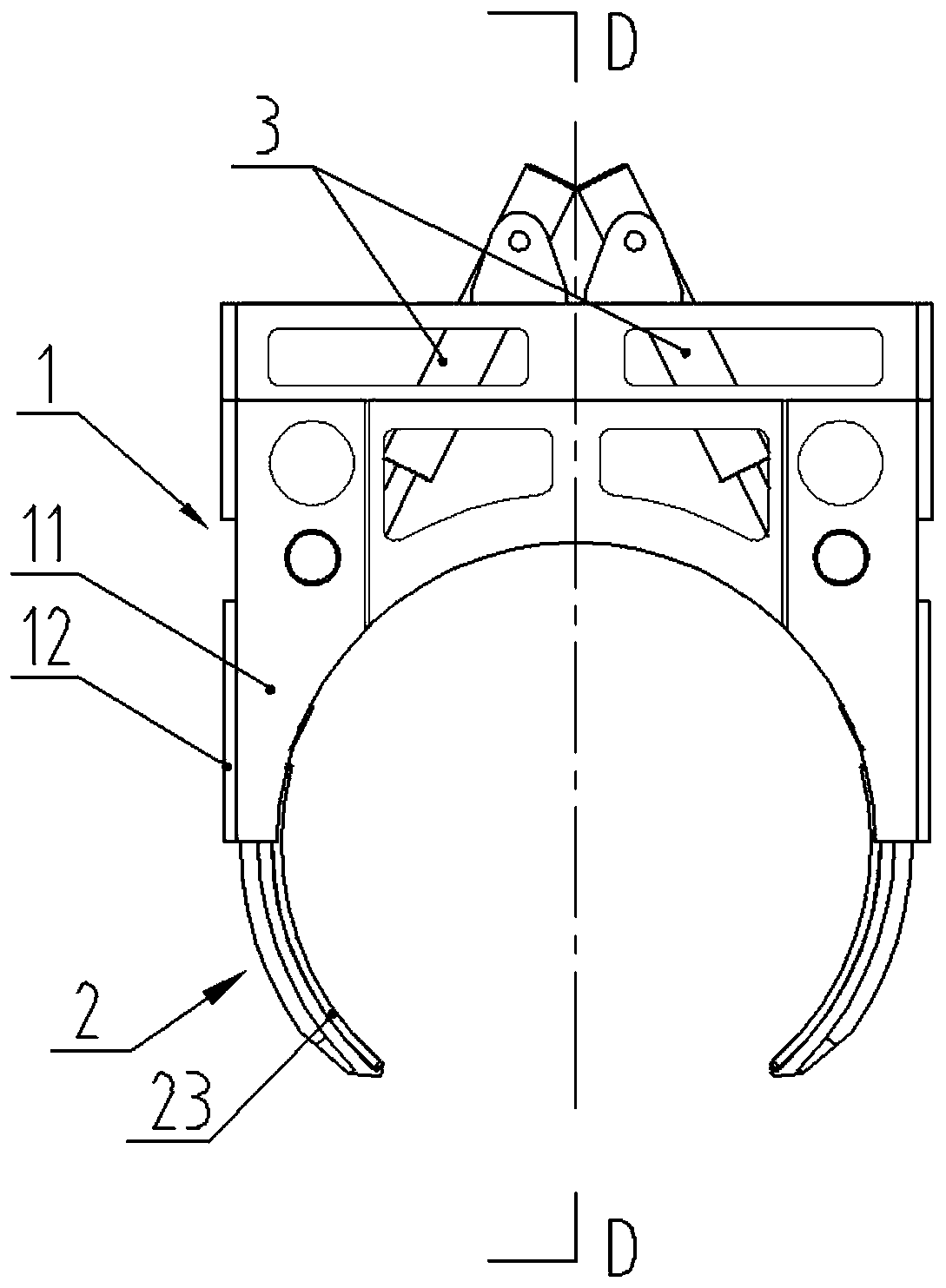

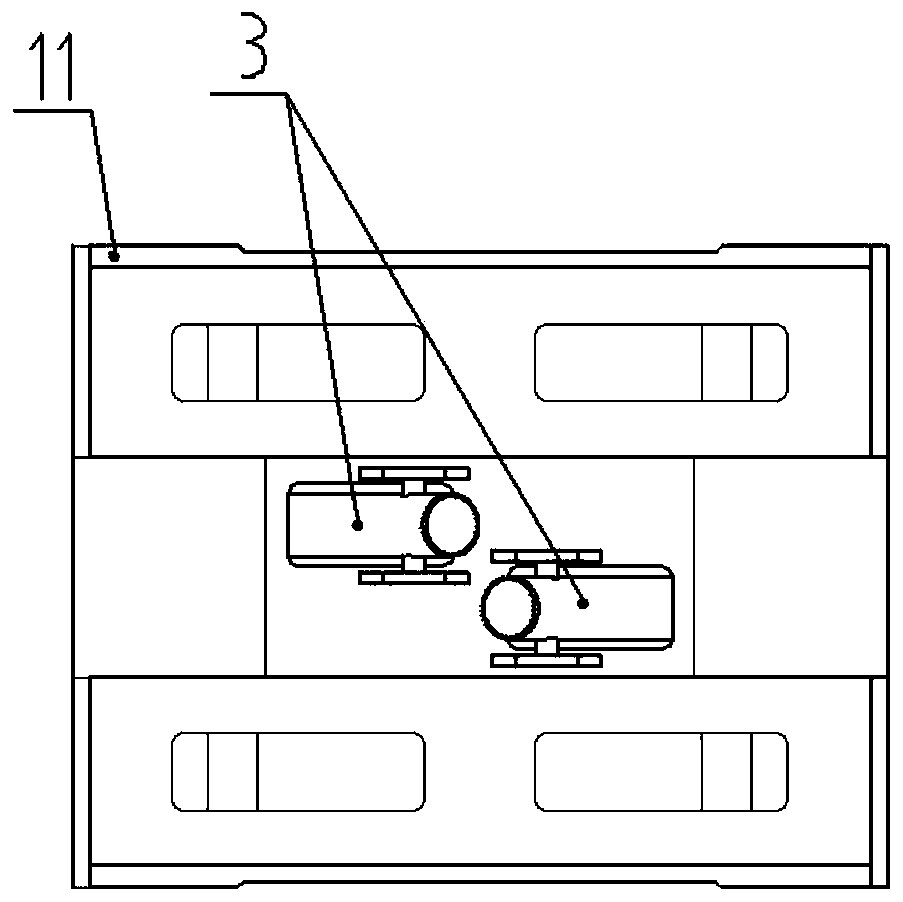

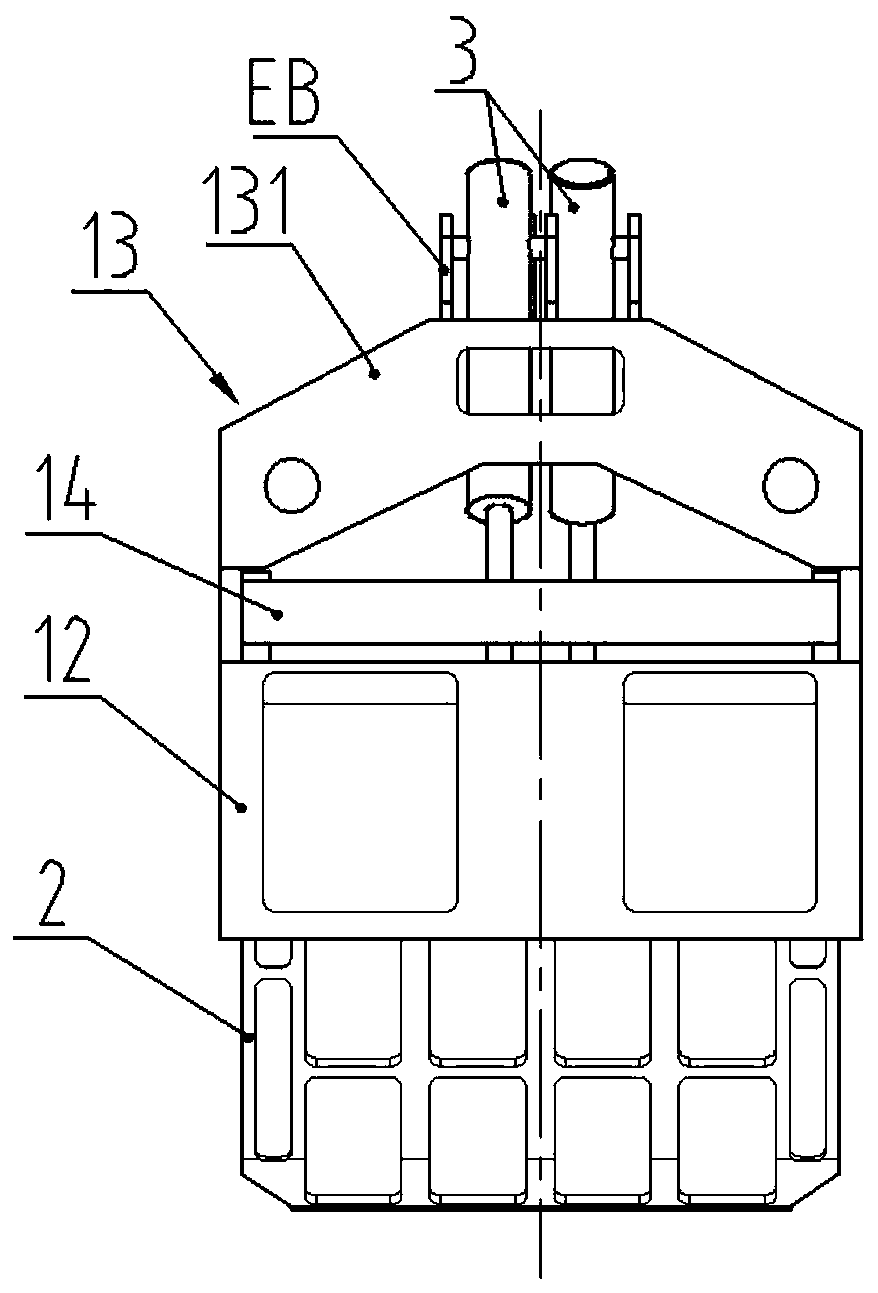

[0034] to combine figure 1 and Figure 11 It can be seen that the heavy-duty clamp suitable for transferring cylindrical thin shells disclosed in this embodiment mainly includes a base 1 , jaws 2 and an oil cylinder 3 . The base 1 is a rectangular frame structure, the jaws 2 are arc-shaped plate holding jaws, a pair of jaws 2 are symmetrically connected to the bottom of the base 1 with respect to the center plane in the length direction of the base 1, and two oil cylinders 3 are arranged obliquely. The cylinder end of the cylinder is hinged on the base 1, and the piston rod end is respectively hinged on the jaws 2. The expansion and contraction of the piston rod of the oil cylinder 3 drives the jaws to slide along the slide rail at the bottom of the base 1, which can clamp the product and release it. Operation of the product.

[0035] to combine Figure 1 to Figure 11 It can be seen that the base 1 includes a radial connecting plate 11 , an axial connecting plate 12 , a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com