A test system and method for storage modulus and loss modulus of o-ring

A technology of loss modulus and storage modulus, which is applied in the field of O-ring storage modulus and loss modulus test system, can solve problems such as inability to explain the condition of O-rings, difficult to simulate working load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0057] Take the measurement of storage modulus and loss modulus of a certain type of O-ring as an example to describe in detail.

[0058] 1. The information of a certain type of O-ring is shown in Table 1.

[0059] Table 1 O-ring rubber sealing ring test pieces and test information

[0060]

[0061] 2. Preparation before measurement

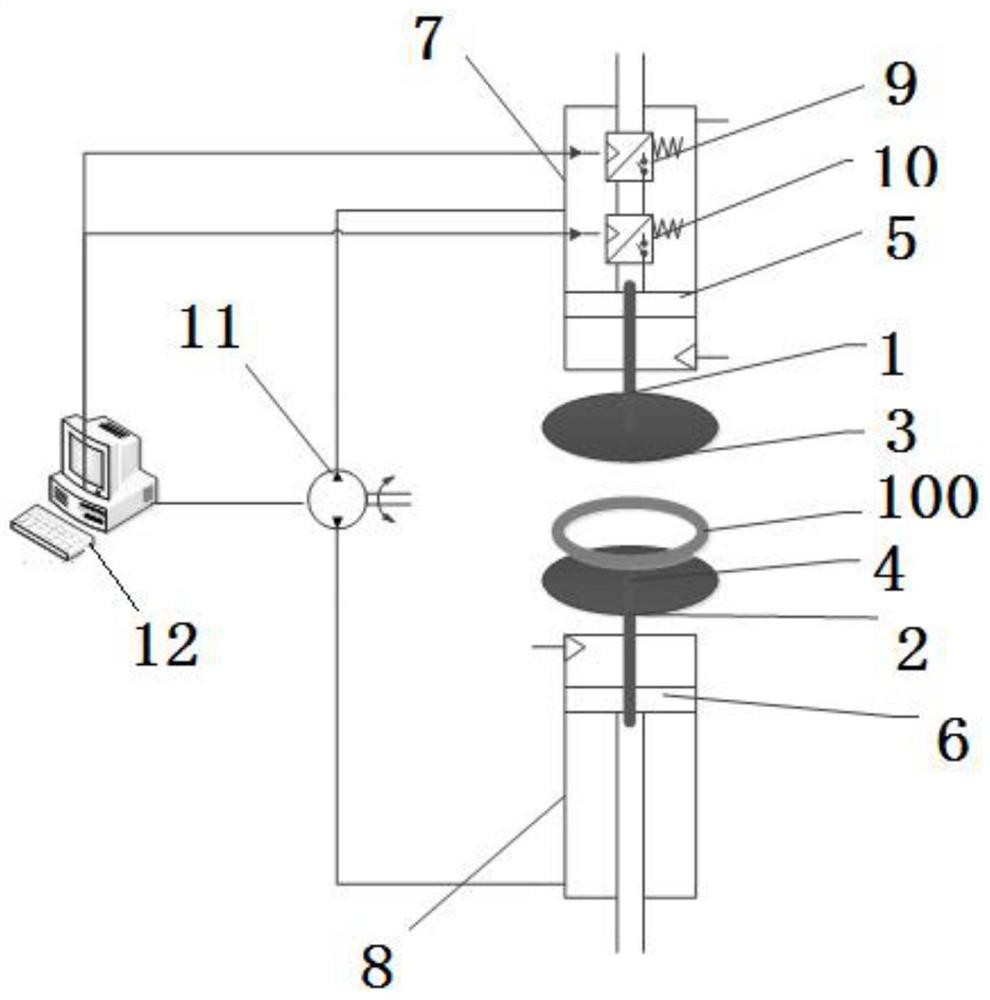

[0062] 1) Place the O-ring on the contact surface 3 of the second jig 2 .

[0063] 2) The control device controls the first cycle stress applying device 7 to go down by means of the electric device, until the contact surface 2 of the first fixture just touches the upper surface of the O-ring, but no force has been formed, record the contact surface of the first fixture 3 positions.

[0064] 3) Continue to control the downward movement of the stress applying device 7 in the first cycle until the contact surface 3 moves downward by 0.75 mm to achieve 25% compression of the O-ring, and record this position as the origin.

[0065] 3. Measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com