Apparatus and method for testing compressed gas dispensing stations

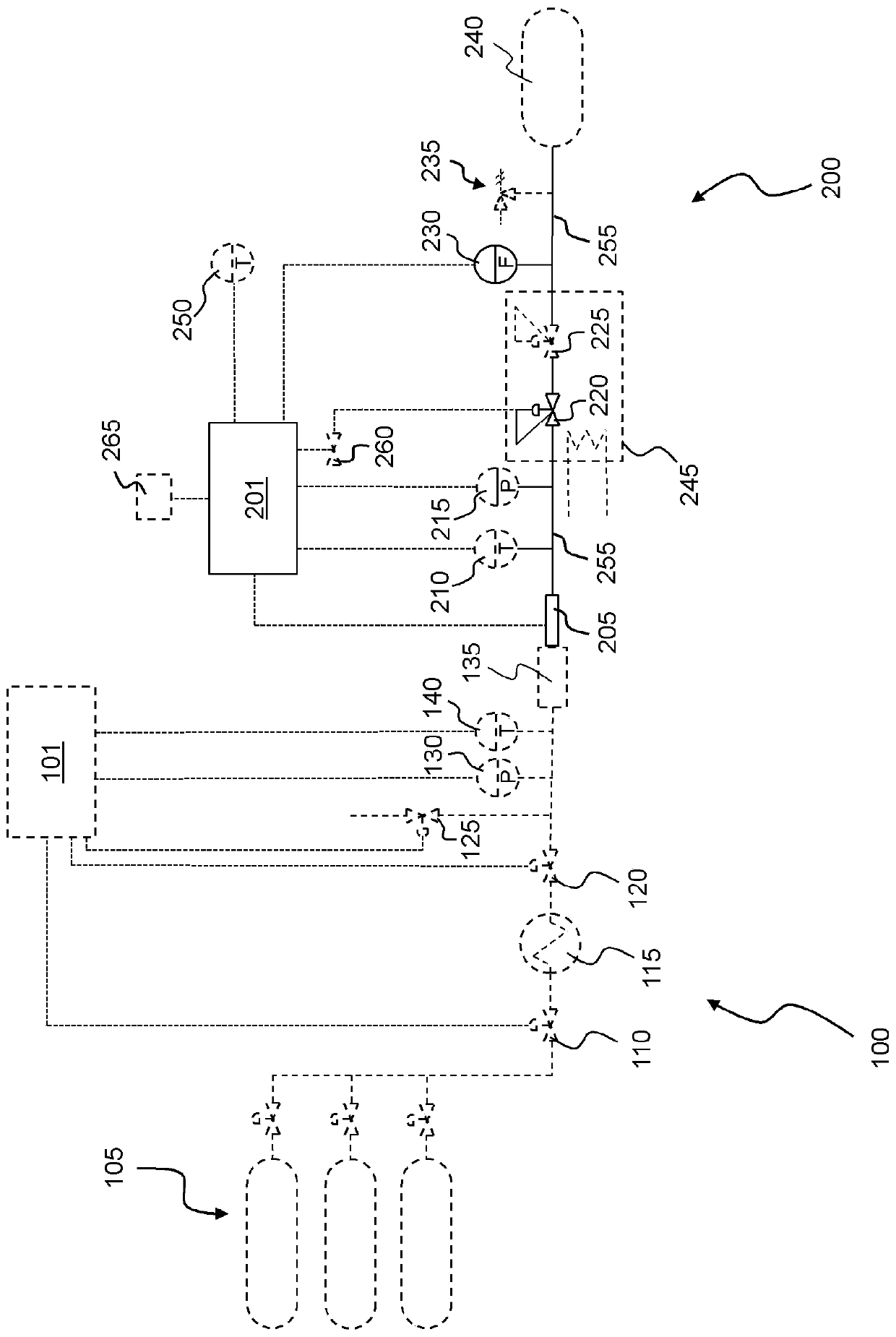

A technology for compressing gas and distributing stations, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, liquid distribution, etc., and can solve problems such as unusable and impractical vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

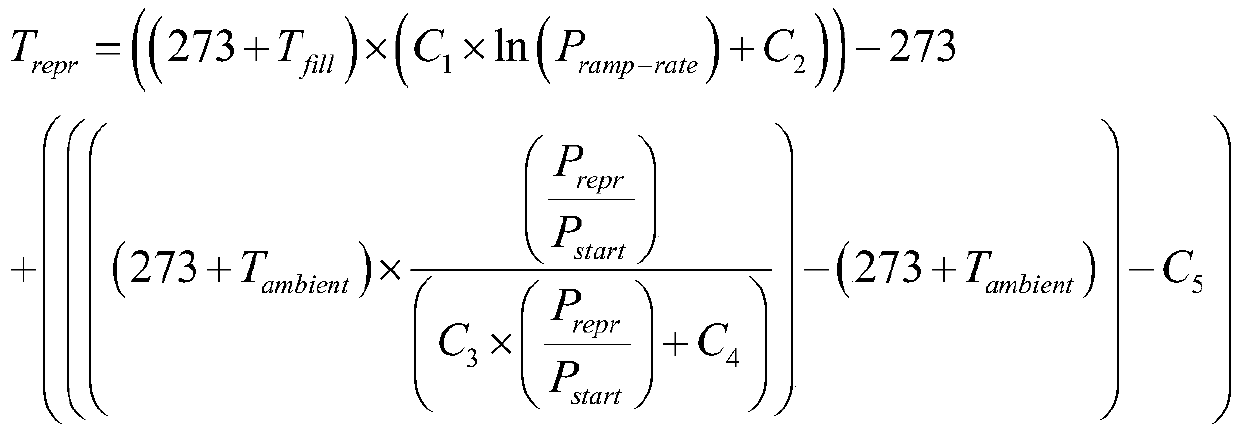

Method used

Image

Examples

Embodiment Construction

[0051] The following detailed description only provides preferred exemplary embodiments, and is not intended to limit the scope, applicability, or configuration of the present invention. On the contrary, the following detailed description of the preferred exemplary embodiment will provide those skilled in the art with a feasible description for implementing the preferred exemplary embodiment of the present invention. It should be understood that without departing from the scope of the present invention defined by the claims In this case, various changes can be made to the function and arrangement of the elements.

[0052] When applied to any feature in the embodiments of the present invention described in the specification and claims, the articles "a" and "an" used herein mean one or more. Unless such limitation is specifically stated, the use of "a" and "an" does not limit the meaning of individual features. The article "the" before a singular or plural noun or noun phrase indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com