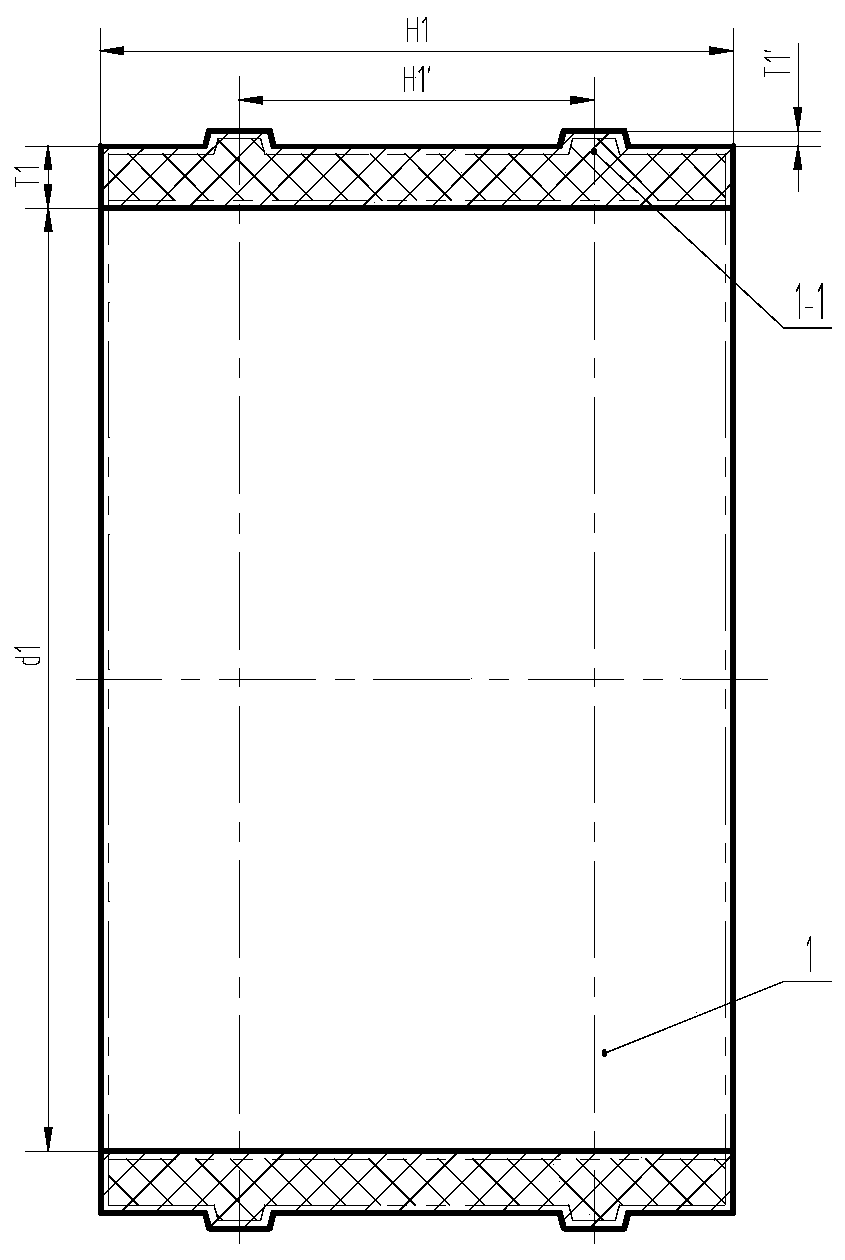

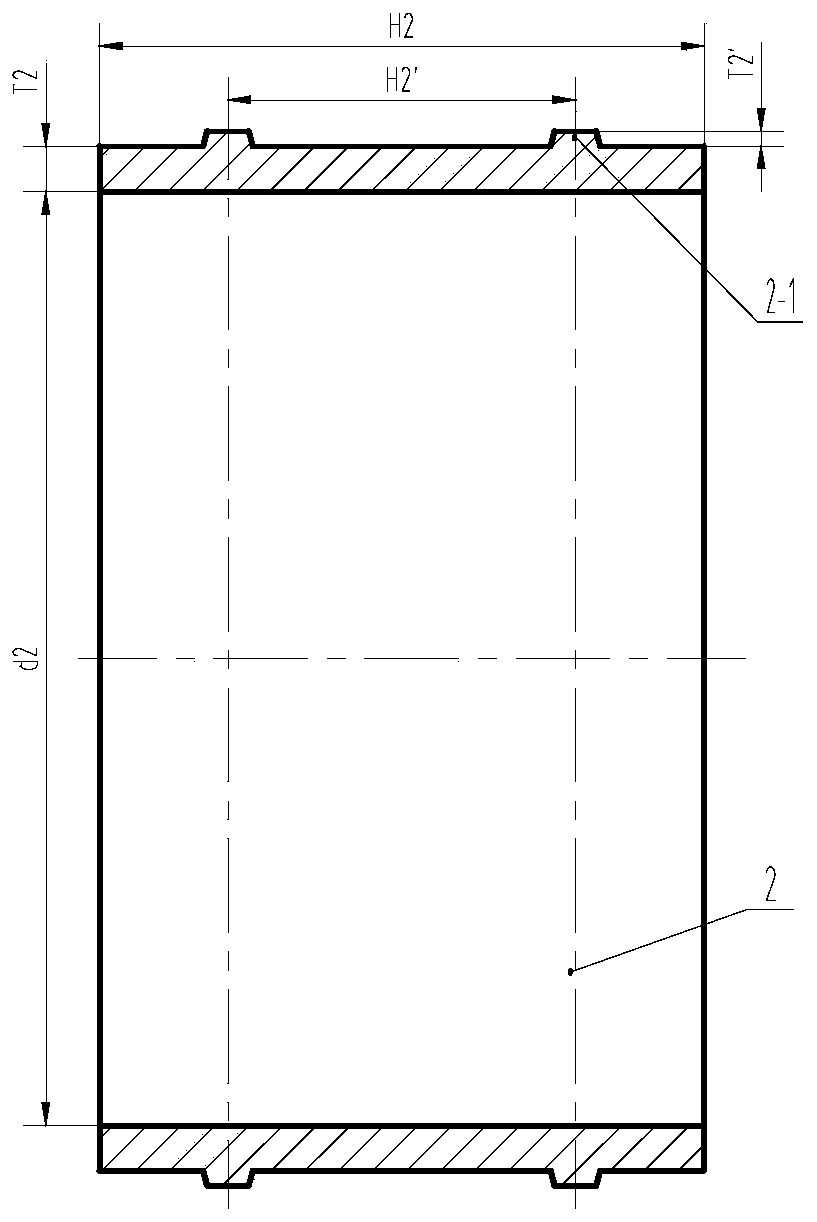

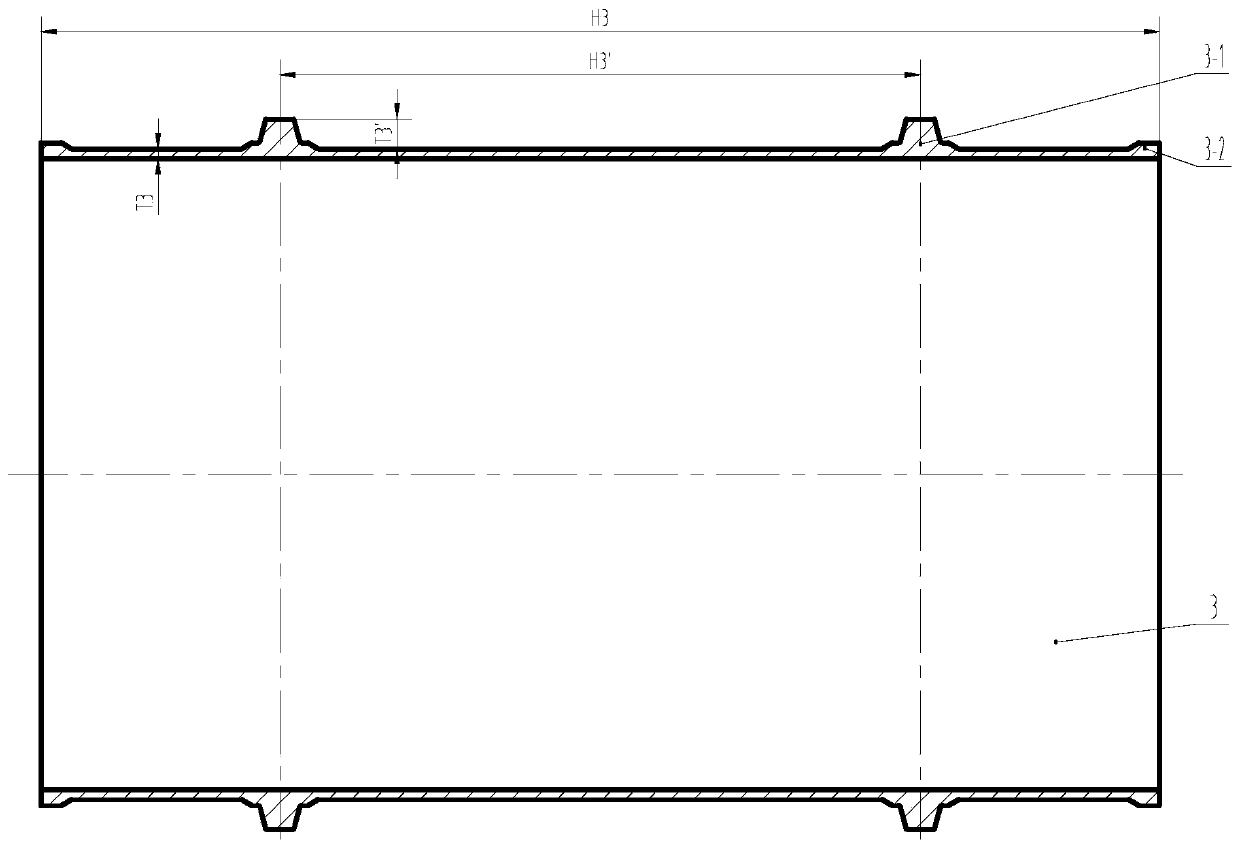

Unfolding and straightening equipment for arc section of thin-walled cylindrical part with outer transverse rib

A technology of thin-walled tubes and transverse ribs, applied in the field of composite forming of metal profiles, to achieve the effect of preventing tearing and preventing wrinkling and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

[0047] The "connection" mentioned in the present invention should be interpreted in a broad sense unless otherwise specified or limited, and may be a direct connection or a connection through an intermediary. In the description of the present invention, it should be understood that the directions indicated by "upper", "lower", "front", "rear", "left", "right", "upper end", "middle", "lower end" etc. Or the positional relationship is based on the orientation or positional relationship shown in the drawings, which is only for the convenience of describing the present invention and simplifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com