A Freezing Tray-Based Stress-Free Fixture

A fixing device and stress-free technology, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems that the workpiece cannot be fixed and affect the processing effect of the workpiece, etc., and achieve the effect of ensuring stability, ensuring the effect of freezing and fixing, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

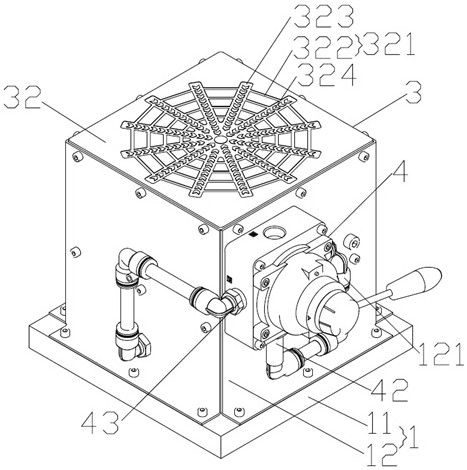

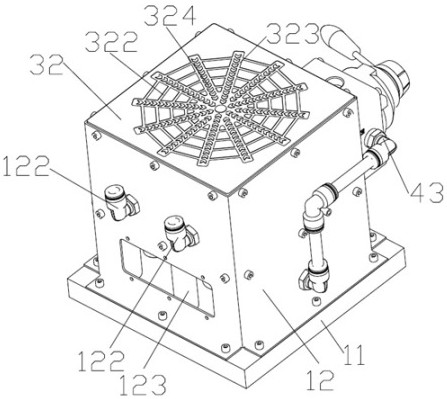

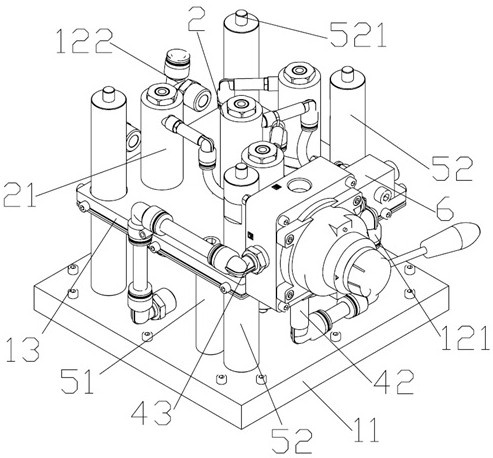

[0020] Please refer to Figure 1 to Figure 5 , a kind of stress-free fixing device based on the freezing plate of the present invention comprises a box body 1, a rapid refrigeration device 2 and a freezing plate 3, the box body 1 includes a box body bottom plate 11 and a box body side wall 12, and the box body side wall 12 is provided with On the case bottom plate 11, the freezing tray 3 is parallel to the case bottom plate 11 and the freezing tray 3 is connected to the side wall 12 of the case body. 32. The heat dissipation surface 31 and the fixed surface 32 are opposite sides of the freezing tray 3. The heat dissipation surface 31 is provided with a heat dissipation network 311. The heat dissipation network 311 includes a plurality of first grooves 312 arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com